Spliced rear panel structure for display device

A display device, splicing technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of insufficient backplane structural strength and outer frame structural strength, difficulty in meeting backplane requirements, and increase in secondary processing costs, etc. Material cost and mold cost, low cost, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

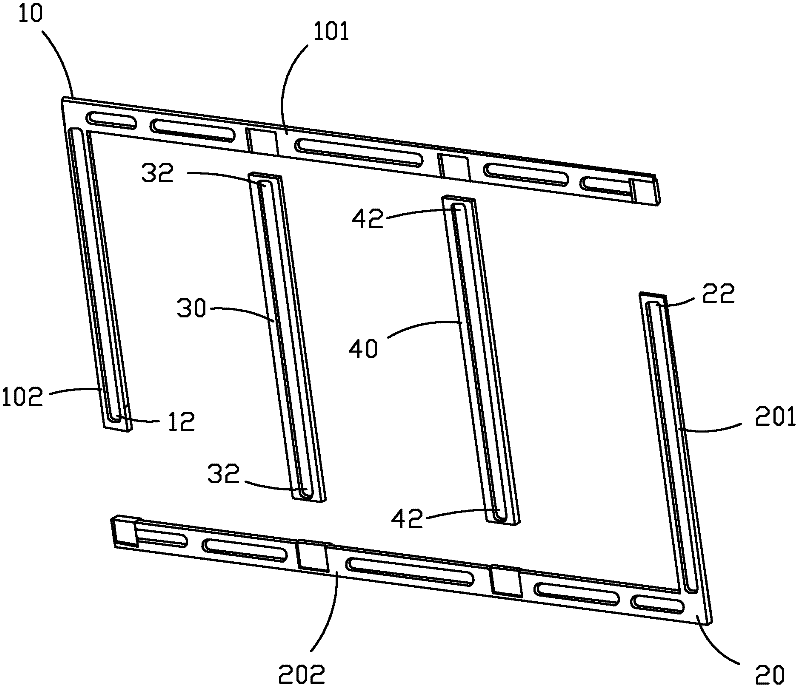

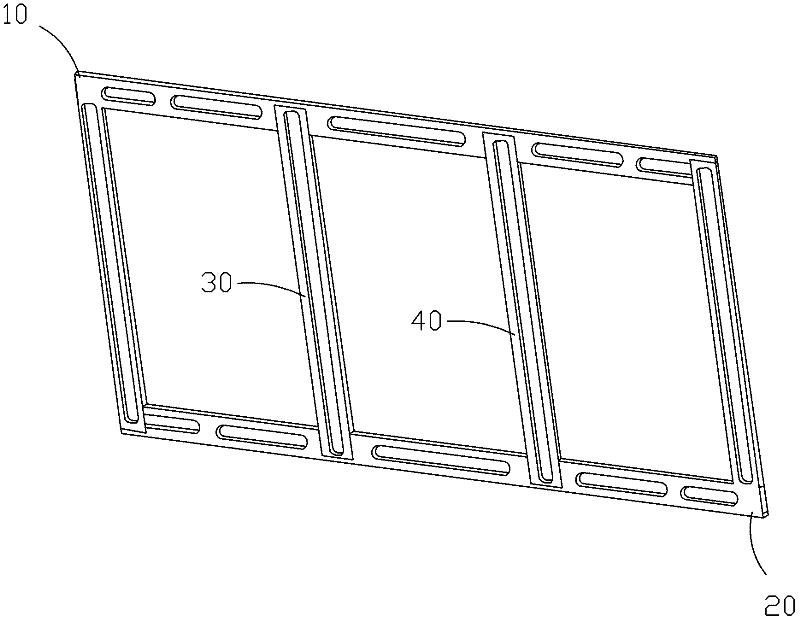

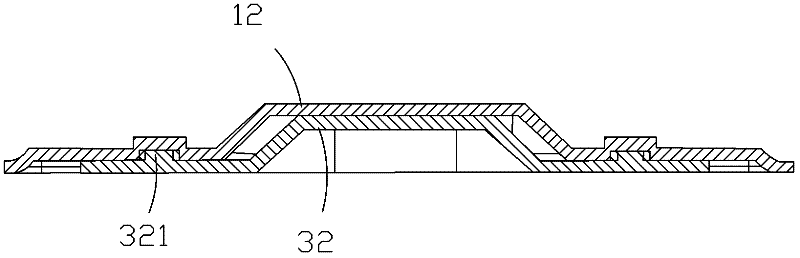

[0026] Such as Figure 1-3 As shown, the present invention provides a spliced back panel structure of a display device, which includes: a first mounting part 10 and a second mounting part 20 which are L-shaped respectively, and a third mounting part 30 and a second mounting part which are in-line respectively. Four mounting parts 40, the two ends of the first mounting part 10 are respectively connected with the two ends of the second mounting part 20 to form a closed outer frame, the third mounting part 30 is placed in the outer frame and the two ends are respectively connected to the first mounting part The component 10 is connected with the second mounting component 20 , the fourth mounting component 40 is placed in the outer frame and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com