Method for manufacturing metal shielding layer of 'SZ' type copper-wire-shielded medium-voltage cable

A technology of metal shielding layer and manufacturing method, which is applied in the direction of cable/conductor manufacturing, power cables with shielding layer/conductive layer, circuits, etc., which can solve the problems of high tightening force of wire cores, achieve good bending performance, and eliminate damage The effect of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: A method for manufacturing the metal shielding layer of an "SZ" type copper wire shielded medium voltage cable,

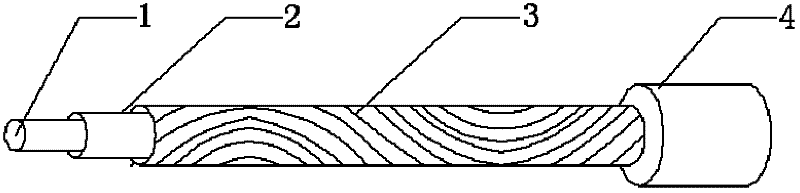

[0018] The power cable includes a conductor unit 1, an insulating layer 2, a metal shielding layer composed of several metal wires 5 and an outer sheath layer 4; the twisting pitch of the metal shielding layer 3 is divided into the first half and the second half ;

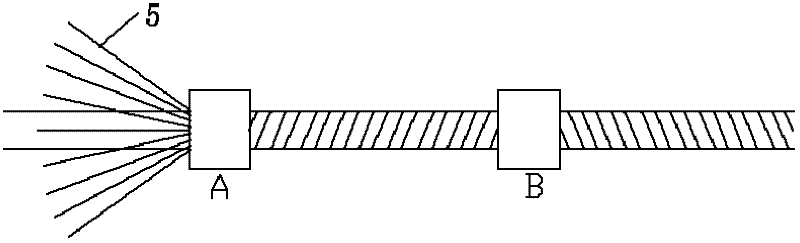

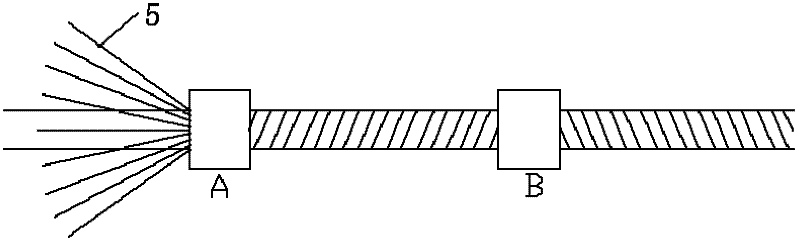

[0019] When the power cable moves forward at a certain speed, the formation process of the first half of the twisted pitch is that the several metal wires 5 rotate clockwise by a first angle, so that the several metal wires 5 wrap clockwise around the surface of the insulating layer 2, and then fix the end of the first half;

[0020] When the power cable moves forward at a certain speed, the formation process of the second half of the twisted pitch is that the plurality of metal wires 5 rotate counterclockwise by a second angle, so that the plurality of metal wires 5 5 wrap around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com