Device for adding iodine into crude salt

A uniaxial, blade technology, applied in the field of salt processing, can solve the problem of poor uniformity of iodized salt, etc., to achieve the effect of easy mixing, large spraying force, and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

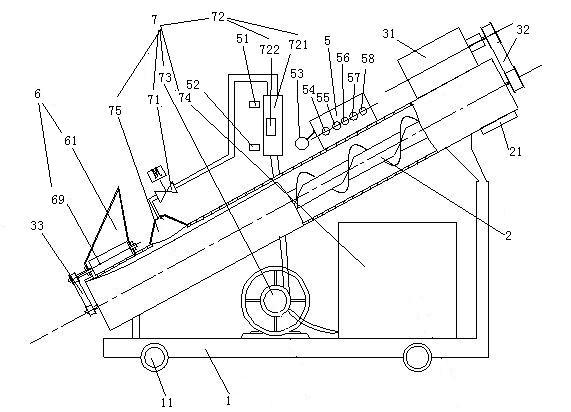

[0021] Embodiment one, see figure 1 , a raw salt iodization device, including a frame 1, a uniaxial paddle type continuous mixing mechanism 2 arranged on the frame 1, a motor 31, an iodine solution spraying mechanism 7 and a control device 5.

[0022] The bottom of the frame 1 is equipped with road wheels 11 . The purpose that road wheel 11 is installed is to improve the convenience when the present invention moves.

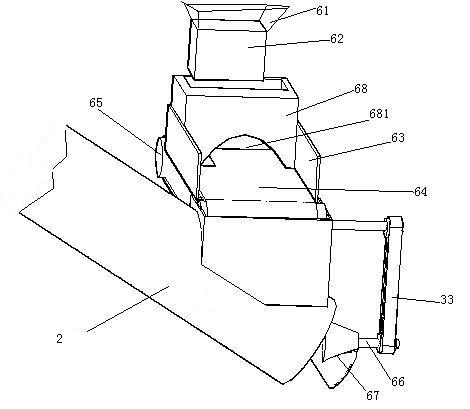

[0023] The uniaxial paddle type continuous mixing mechanism 2 is arranged obliquely, and its right end is high and its left end is low. The right end of the uniaxial paddle type continuous mixing mechanism 2 is provided with a discharge port 21, and the left end of the uniaxial paddle type continuous mixing mechanism 2 is provided with a raw salt quantitative feeding mechanism 6, and the nozzle 4 is located at the discharge port 21 and Between the former salt quantitative feeding mechanism 6.

[0024]The iodine liquid spraying mechanism comprises shower head 7...

Embodiment 2

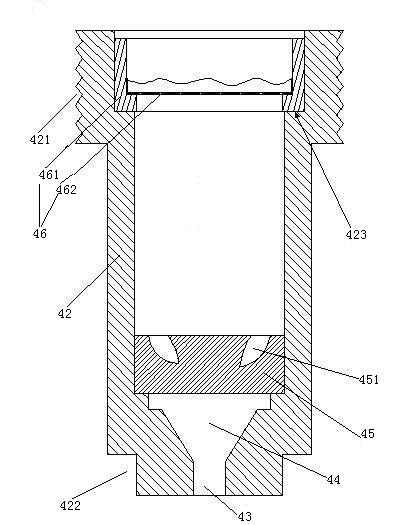

[0031] Embodiment two, the difference with embodiment one is, refer to figure 2 , the spray head 75 includes the housing 42 . The housing 42 is made of stainless steel, the housing 42 is cylindrical, and the upper end of the housing 42 is larger than the lower end.

[0032] A connection thread 421 is provided on the outer surface of the upper end of the housing 42 . The purpose of providing the connecting thread 421 is to facilitate the connection of the casing 42 to the nozzle control solenoid valve 71 .

[0033] Two notches 422 are symmetrically provided on the edge of the outer surface of the lower end of the housing 42 . The purpose of setting the cutout 422 is to facilitate the rotation of the housing 42 .

[0034] A liquid outlet 43 is opened at the center of the lower end surface of the housing 42 . The liquid outlet 43 is a cylindrical hole.

[0035] The liquid inlet end of the liquid outlet 43, that is, the upper end in the figure, is provided with a conical cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com