Optical glass, preform product and optical element

A kind of optical glass and glass technology, which is applied in the field of optical glass, preforms and optical components, can solve the problems of reduced spectral transmittance, large exposure effect, and difficulty in maintaining spectral transmittance, so as to reduce exposure effect and inhibit The effect of spectral transmittance and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

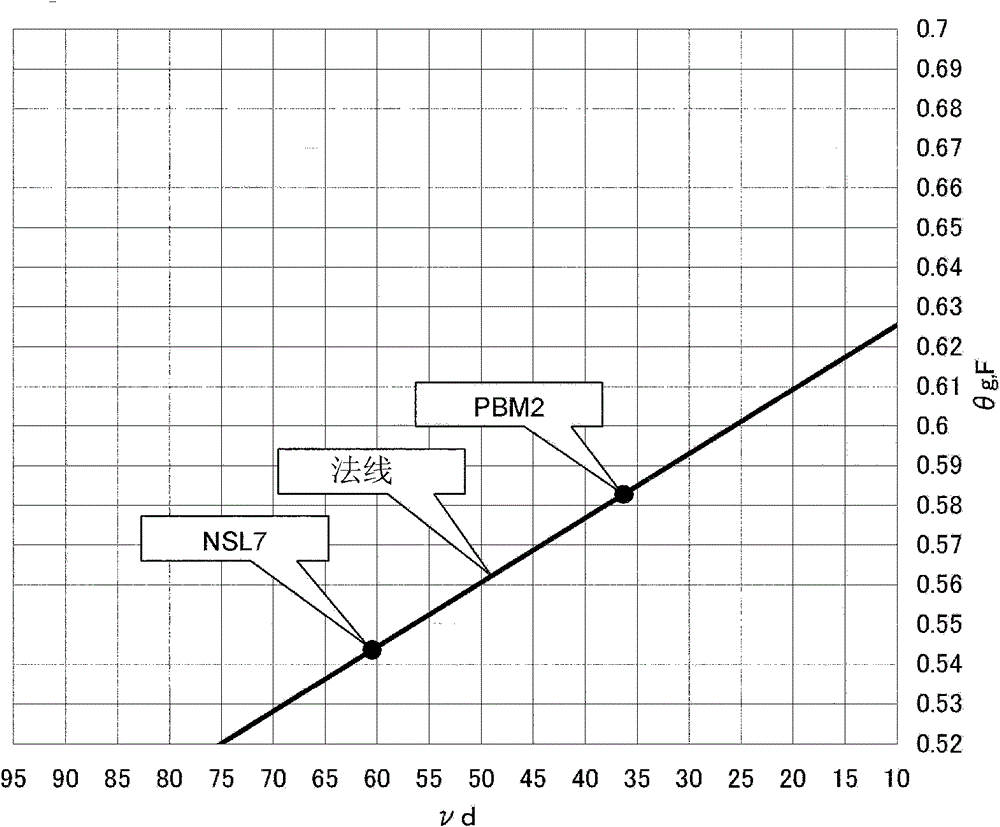

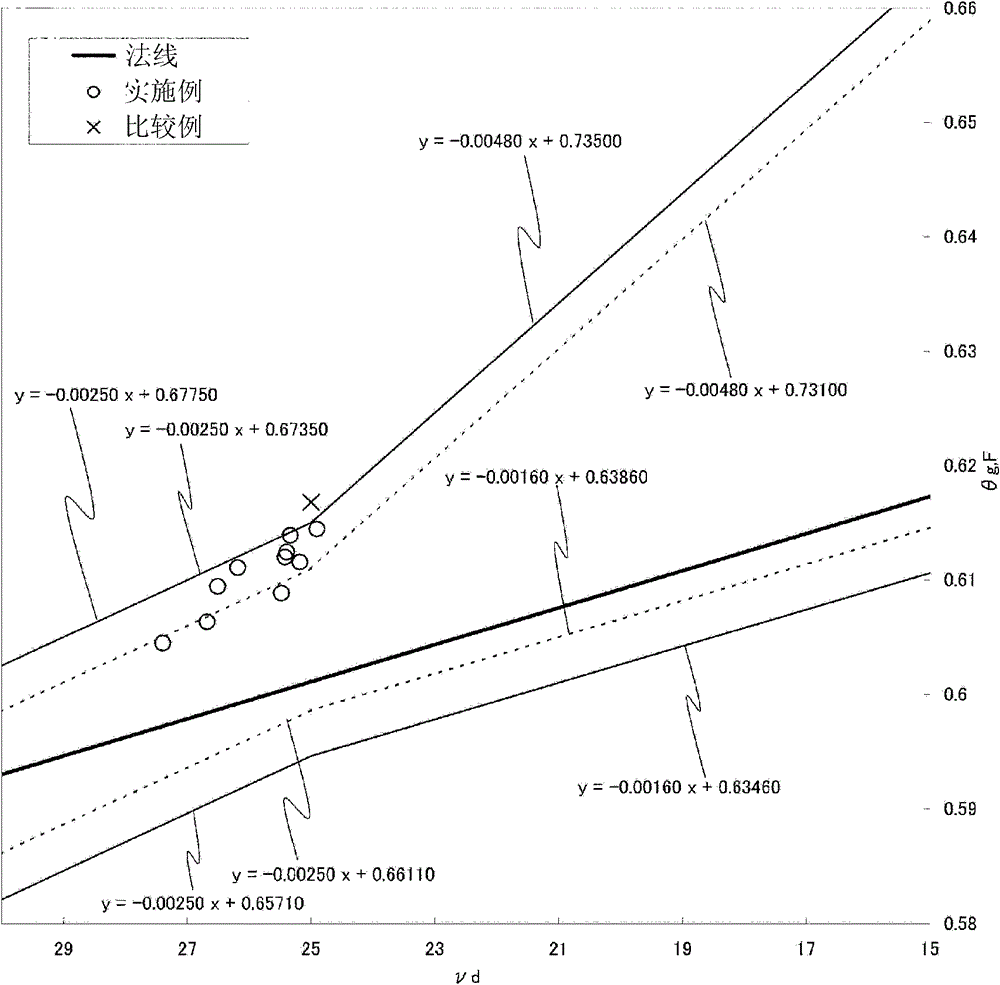

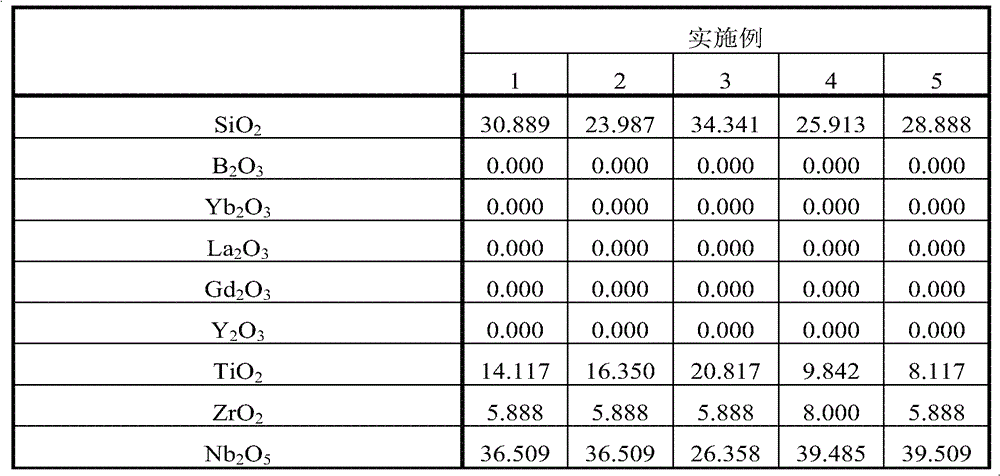

[0063] The optical glass of the present invention, relative to the total mass of glass converted into oxide composition, contains SiO 2 Composition 10.0%~40.0% and Nb 2 o 5 The composition is 1.0% to 50.0%, and has an Abbe number of 15 or more and 30 or less (v d ), in partial dispersion ratio (θg, F) and Abbe number (v d ), between v d Within the range of ≤25, satisfy (-0.00160×v d +0.63460)≤(θg, F)≤(-0.00480×v d +0.73500), at v d In the range of >25, satisfy (-0.00250×v d +0.65710)≤(θg, F)≤(-0.00250×v d +0.67750). By using SiO 2 Composition and Nb 2 o 5 The glass has high refractive index and high dispersion, and at the same time, the partial dispersion ratio (θg, F) can be made close to the normal line, and the spectral transmittance of the glass after ultraviolet irradiation can be reduced. Deterioration and devitrification and / or clouding of glass after reheating. Therefore, it is possible to obtain an Abbe number (v d ) and easy to perform mold press mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com