Gluing system and gluing method of base plates

A substrate and gluing technology, applied in the field of OLED display manufacturing, can solve problems such as affecting the gluing processing efficiency, occupying a large space for equipment, and being difficult to control, and achieving the effect of high gluing processing efficiency, compact structure, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

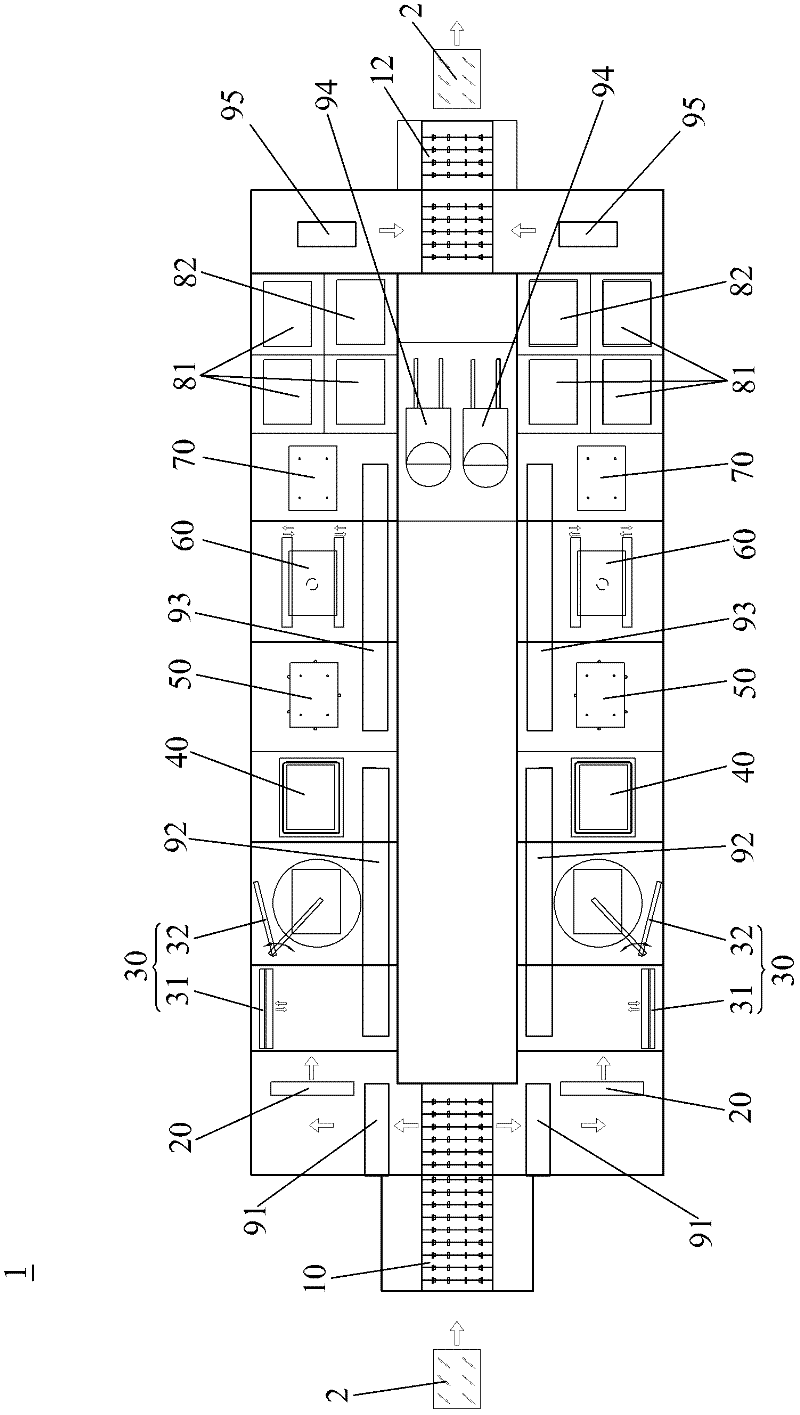

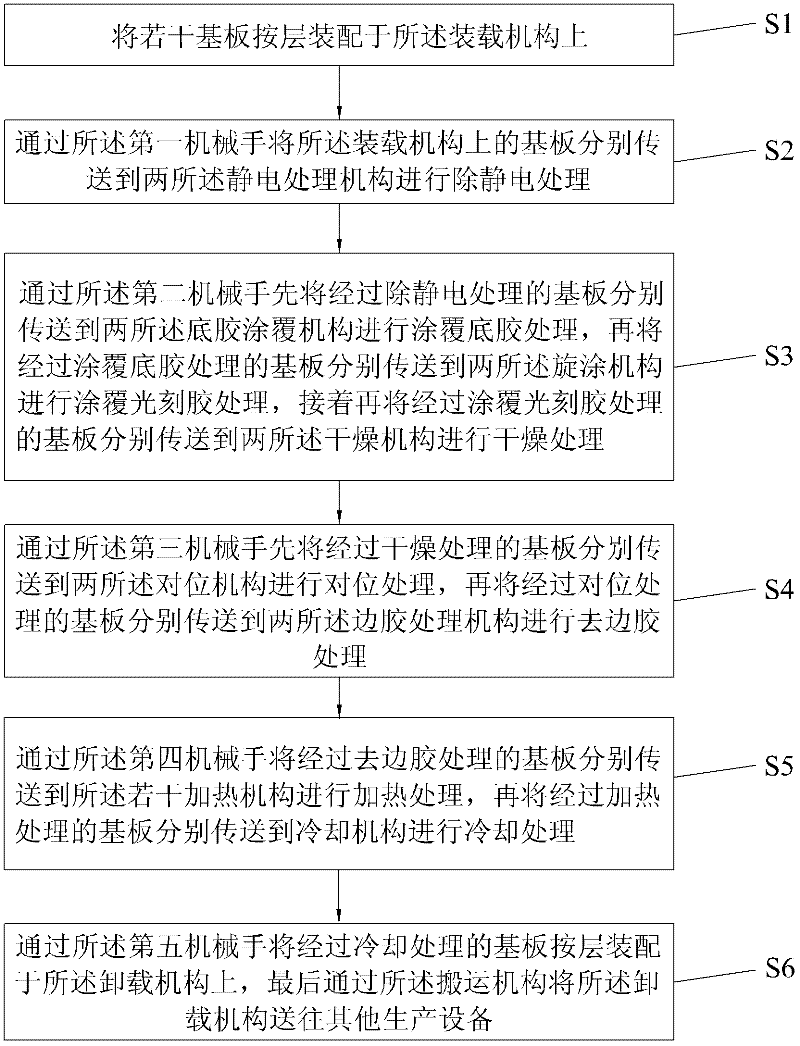

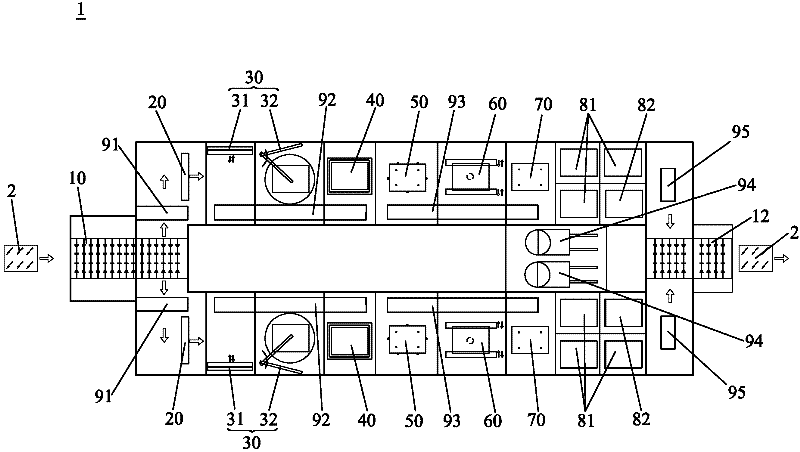

[0027] refer to figure 1 , the substrate gluing system 1 of the present invention includes a loading mechanism 10, a gluing mechanism 30, a drying mechanism 40, and a transmission mechanism. The loading mechanism 10 has a layered structure, and several substrates 2 are assembled on the layered layers of the loading mechanism 10. Structurally, the gluing mechanism 30 is arranged between the loading mechanism 10 and the drying mechanism 40 , and the loading mechanism 10 , gluing mechanism 30 and drying mechanism 40 are arranged in sequence to form a production line. Specifically, the production line includes two groups of the gluing mechanism 30 and two groups of the drying mechanism 40, the gluing mechanism 30 includes a primer coating mechanism 31 and a spin coating mechanism 32 arranged in sequence, the primer The coati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap