Normal-temperature color pavement cold paving material used in summer or high-temperature areas and preparation technology thereof

A preparation process and technology of cold patching material, which is applied in the field of cold patching material for colored pavement, to achieve excellent waterproof performance, not easy to fade, and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

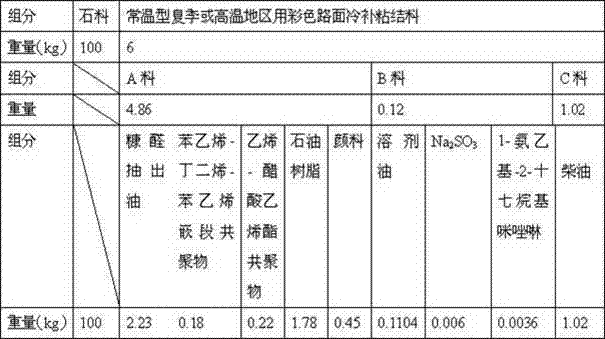

[0027] The raw materials used in the production of 106kg normal temperature cold patch material for summer or high temperature areas are as follows:

[0028]

[0029] Its preparation process is as follows:

[0030] ① Preparation of material A: firstly clean up the mixing equipment, then add furfural extract oil with a weight of 2.23kg, styrene-butadiene-styrene block copolymer with a weight of 0.18kg, and a weight of 0.22kg Ethylene-vinyl acetate copolymer, petroleum resin with a weight of 1.78kg, and pigment with a weight of 0.45kg. During the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C, and stirred at 170°C for 60 Minutes later, 4.86kg of cementitious material A material was prepared by shearing;

[0031] ② Preparation of material B: put solvent oil with a weight of 0.1104kg, Na with a weight of 0.006kg 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline with a weight of 0.0036 is mixed and stirred to make 0.12kg modified...

Embodiment 2

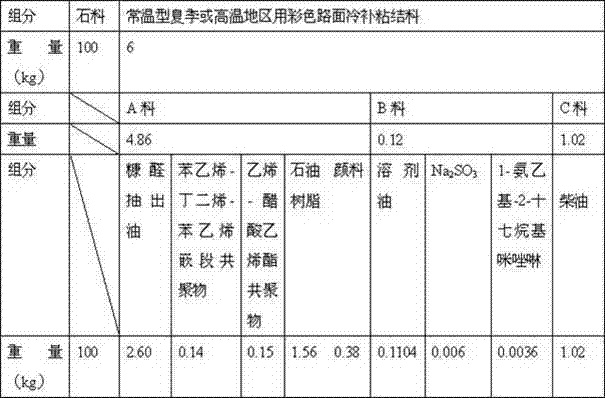

[0035] The raw materials used in the production of 106kg normal temperature cold patching material for colored pavement in summer or high temperature areas are as follows:

[0036]

[0037] Its preparation process is as follows:

[0038]① Preparation of material A: first clean up the stirring equipment, then add furfural extract oil with a weight of 2.60kg, styrene-butadiene-styrene block copolymer with a weight of 0.14kg, and a weight of 0.15kg Ethylene-vinyl acetate copolymer, petroleum resin with a weight of 1.56kg, and pigment with a weight of 0.38kg. During the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C, and stirred at 170°C for 60 Minutes later, 4.86kg of cementitious material A material was prepared by shearing;

[0039] ② Preparation of material B: put solvent oil with a weight of 0.1104kg, Na with a weight of 0.006kg 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline with a weight of 0.0036 is mixed and stirred t...

Embodiment 3

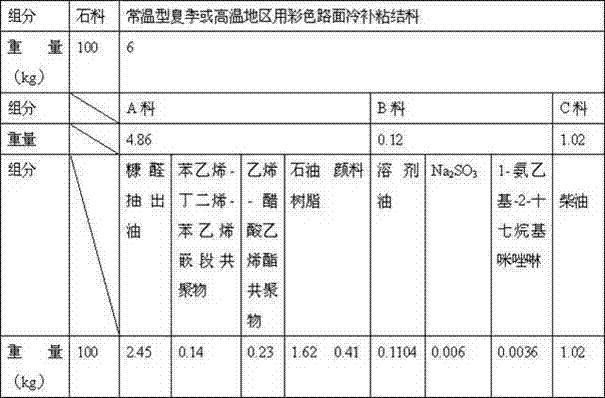

[0043] The raw materials used in the production of 106kg normal temperature cold patch material for summer or high temperature areas are as follows:

[0044]

[0045] Its preparation process is as follows:

[0046] ① Preparation of material A: first clean up the stirring equipment, then add furfural extract oil with a weight of 2.45kg, styrene-butadiene-styrene block copolymer with a weight of 0.14kg, and a weight of 0.23kg Ethylene-vinyl acetate copolymer, petroleum resin with a weight of 1.62kg, and pigment with a weight of 0.41kg. During the addition process, the stirring equipment kept stirring, and the above mixture was heated to 170°C, and stirred at 170°C for 60 Minutes later, 4.86kg of cementitious material A material was prepared by shearing;

[0047] ② Preparation of material B: put solvent oil with a weight of 0.1104kg, Na with a weight of 0.006kg 2 SO 3 1-aminoethyl-2-heptadecyl imidazoline with a weight of 0.0036 is mixed and stirred to make 0.12kg modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com