Production method for a metal nanostructure using an ionic liquid

A metal nanostructure, ionic liquid technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of forming metal nanostructures and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

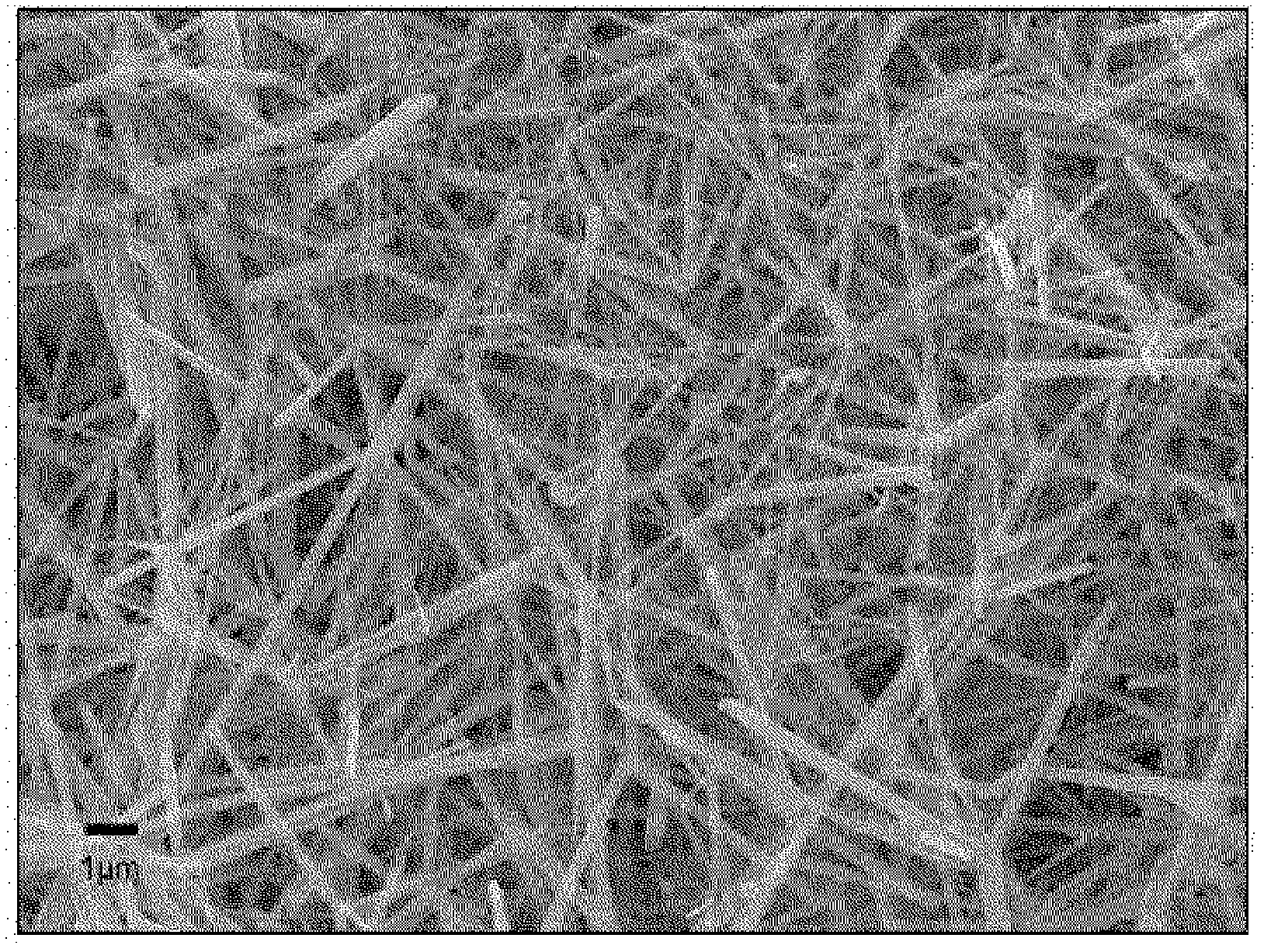

[0042] In a round bottom flask, 50 mL of silver nitrate (AgNO 3 ) dissolved in ethylene glycol to form a solution with a concentration of 0.1M and 50mL of 1-butyl-3-methylimidazolium methyl sulfate (1-butyl-3-methylimidazolium methyl sulfate) dissolved in ethylene glycol to form a concentration The 0.15 M solutions were mixed to form a mixed solution. Subsequently, the mixed solution was stirred and allowed to react at a temperature of 160° C. for 60 minutes, and then cooled to room temperature. Subsequently, the cooled mixed solution was filtered with a filter having a pore size of 1 μm, and then observed with a scanning electron microscope. As a result, metal nanowires formed, such as figure 1 shown. It can be observed that the metal nanowires have a diameter of about 220 nm and a length of about 7 μm.

Embodiment 2

[0044] In a round bottom flask, 10 mL of silver nitrate (AgNO 3 ) was dissolved in 1,3-propanediol to form a solution with a concentration of 0.2M and 10 mL of 1-ethyl-3-methylimidazolium methyl sulfate (1-ethyl-3-methylimidazolium methyl sulfate) was dissolved in 1,3- A solution with a concentration of 0.3 M in propylene glycol was mixed to form a mixed solution. Subsequently, the mixed solution was stirred and allowed to react at a temperature of 100° C. for about 30 minutes, and then cooled to room temperature. Subsequently, the cooled mixed solution was filtered with a filter having a pore size of 1 μm, and then observed with a scanning electron microscope. As a result, it was found that the formed metal nanowires had a diameter of about 180 nm and a length of about 10 μm.

Embodiment 3

[0046] In a round bottom flask, 10 mL of silver nitrate (AgNO 3 ) dissolved in 1,2-propylene glycol to form a solution with a concentration of 0.2M and 10 mL of 1-ethyl-3-methylimidazolium methyl sulfate dissolved in 1,3-propylene glycol to form a solution with a concentration of 0.3M. to form the first mixed solution, followed by silver nitrate (AgNO 3 ), sodium lauryl sulfate was added into the first mixed solution to form the second mixed solution. Subsequently, the second mixed solution was stirred and reacted at a temperature of 100° C. for about 30 minutes, and then cooled to room temperature. Subsequently, the cooled mixed solution was filtered with a filter having a pore size of 1 μm, and then observed with a scanning electron microscope. As a result, it was found that the formed metal nanowires had a diameter of about 80 nm and a length of about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com