Flexible and rapid clamp device

A fixture device, fast technology, applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of increasing the cost of process equipment and production preparation cycle, deformation of the crankshaft, and lack of auxiliary positioning function, so as to shorten the production preparation cycle , the effect of improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

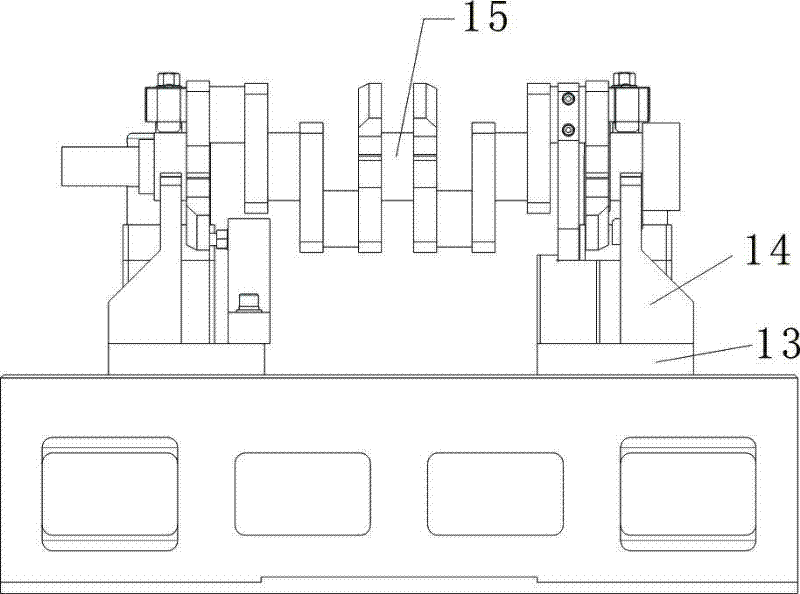

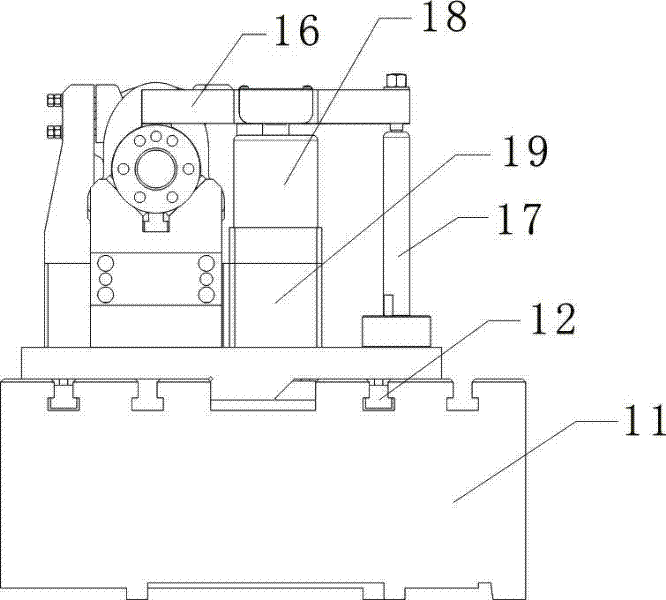

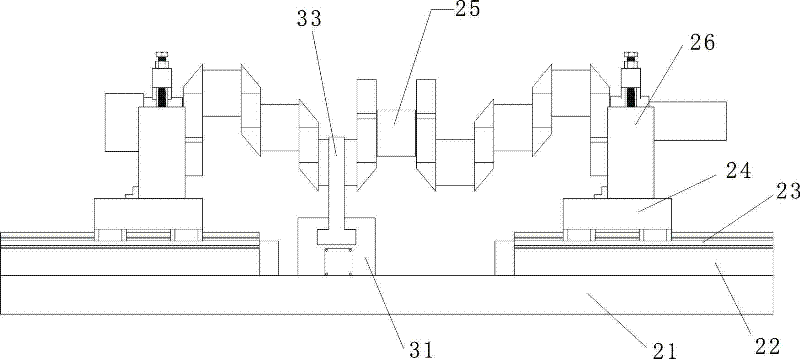

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: image 3 , 4 , 5, the present invention mainly includes a base plate 21, a guide rail support 22 is respectively arranged on the left and right sides of the base plate 21, and a carriage 24 is respectively installed by a guide rail 23 on it. The V-shaped block 26 of neck, on the slewing bearing journal of crankshaft, clamp with rotary oil cylinder pressing plate mechanism, the crank throw side in the middle of crankshaft 25 is provided with an automatic centering mechanism and clamps to the crank throw both sides to realize auxiliary positioning.

[0015] Figure 4 The rotary oil cylinder pressing plate mechanism shown includes an upper pressing plate 27 pressed against the crankshaft on the slewing bearing journal, one end of the pressing plate 27 is fixed to the oil cylinder base 29 through an adjustable screw 28, and the oil cylinder base 29 is installed An oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com