Knitting machine

A technology of knitting machine and frame, applied in the directions of knitting, weft knitting, warp knitting, etc., can solve the problems of cumbersome manufacturing and installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

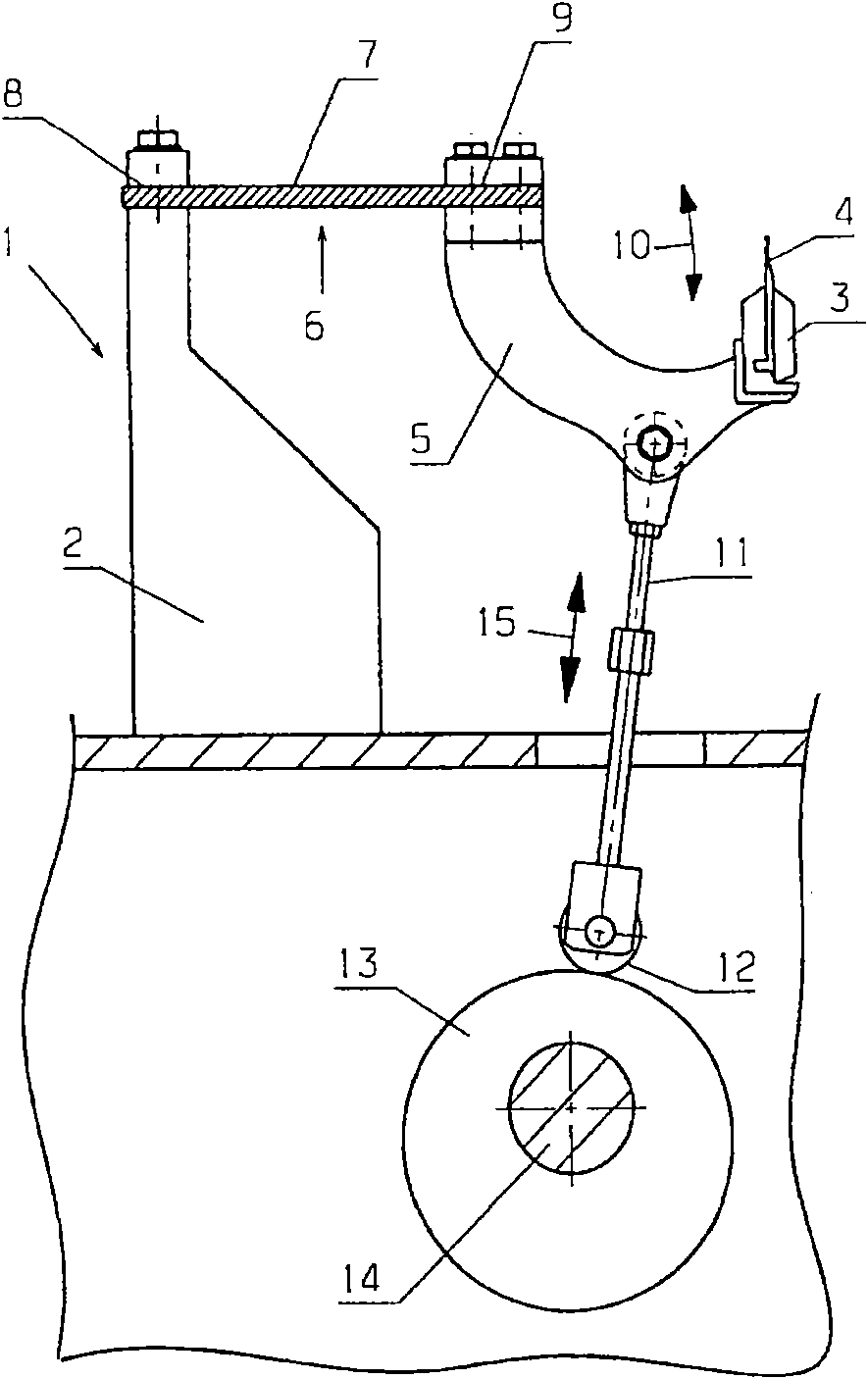

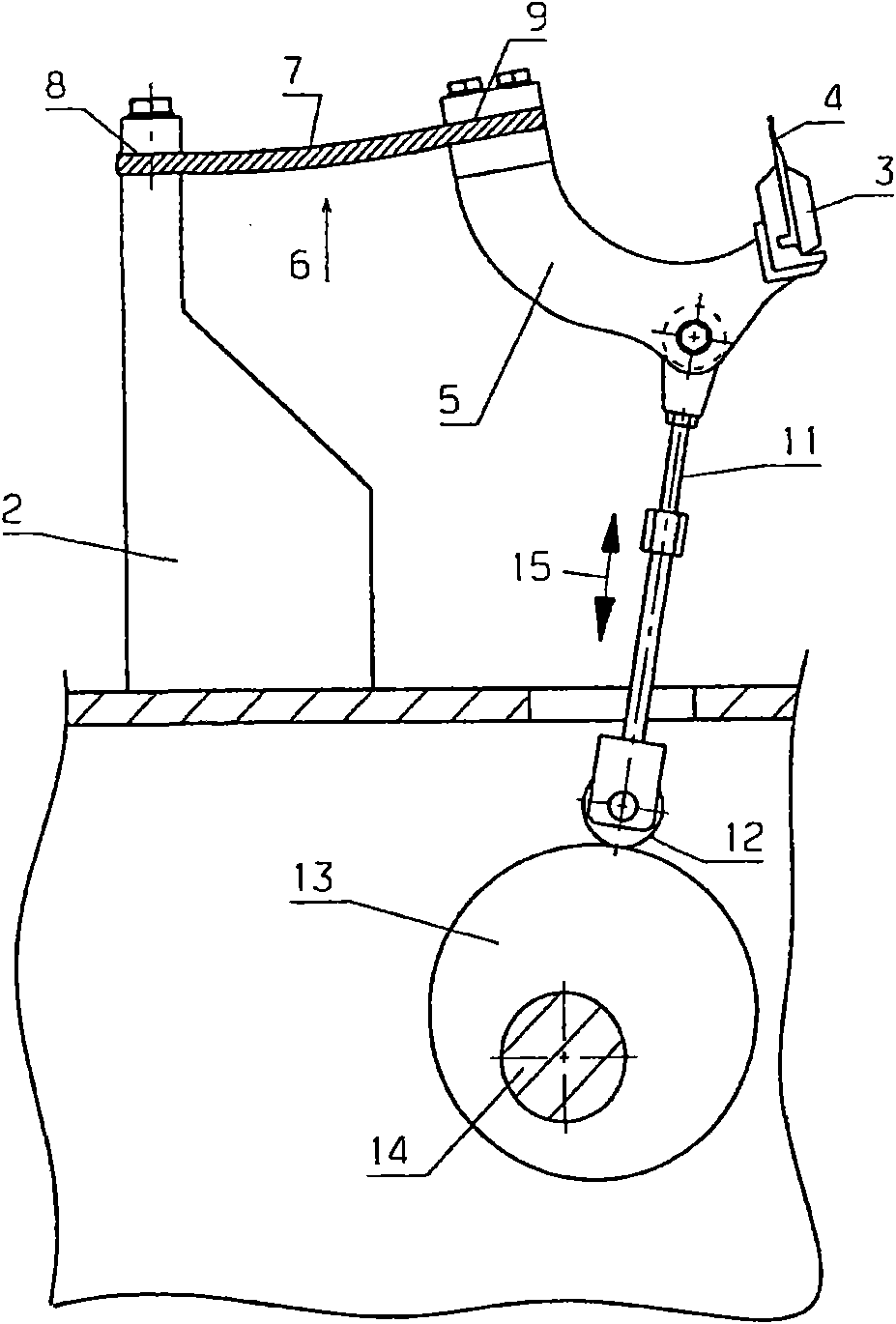

[0021] figure 1 A schematic partial sectional view of a knitting machine 1 with a frame 2 and a loop forming tool bar 3, in the present case a needle bar with needles 4, these The knitting needles are arranged one after the other perpendicular to the drawing surface.

[0022] For the sake of clarity, the other bars of the knitting machine 1 are not shown, but are of course present in practice.

[0023] The looping tool bar 3 is fixed on the front end of the support rod 5 . The support rod is connected with the frame 2 through a bending joint device 6 .

[0024] In the present case, the bending joint has a leaf spring 7 made of fiber-reinforced plastic. The leaf springs are connected to the frame 2 via a momentary fastening (momentenfest) connection 8 . Furthermore, the leaf spring 7 is connected to the support rod 5 by means of an instantaneously fixed connection mechanism 9 . Immediately fixed connecting mechanism 8,9 makes looping tool bar 3 swing as shown by double arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com