Film forming apparatus and film forming method

A film-forming device and a film-forming method technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of film quality decline, falling, and adhesion to the substrate surface, etc., and achieve the effect of simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

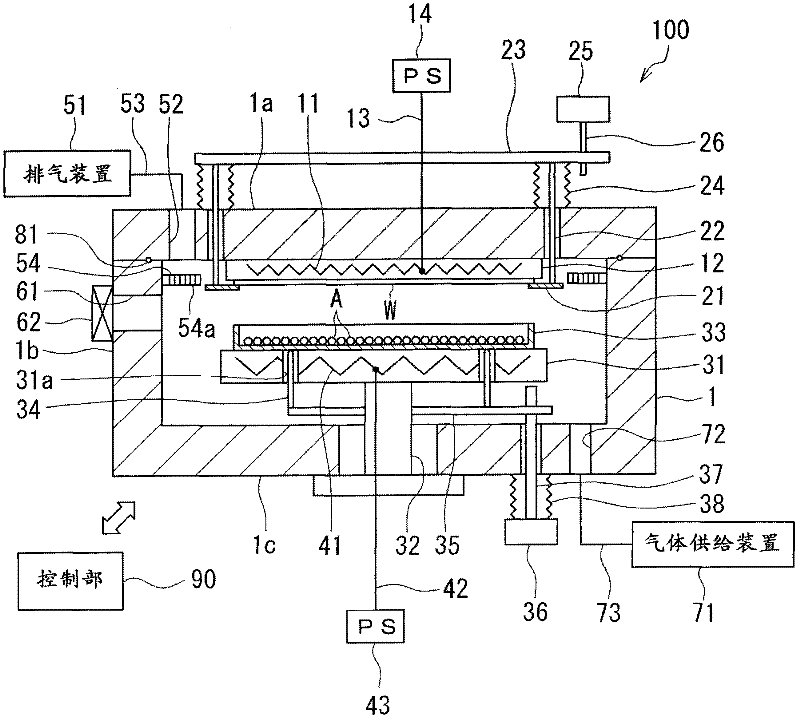

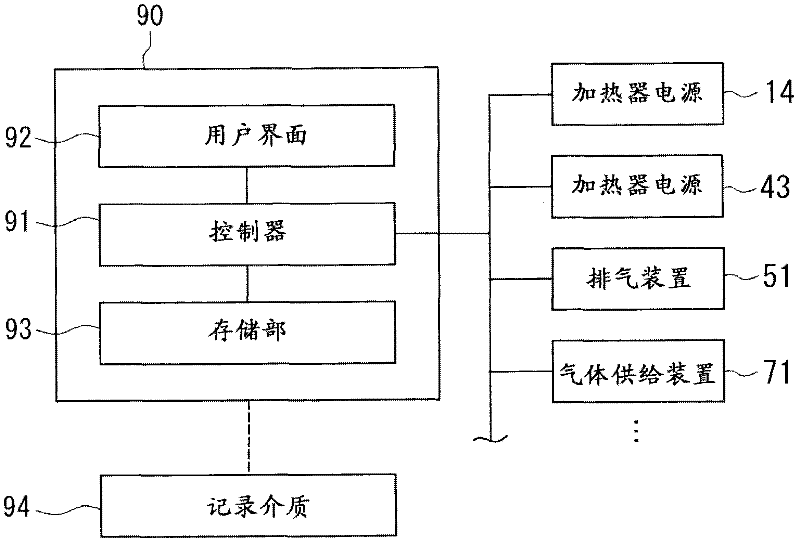

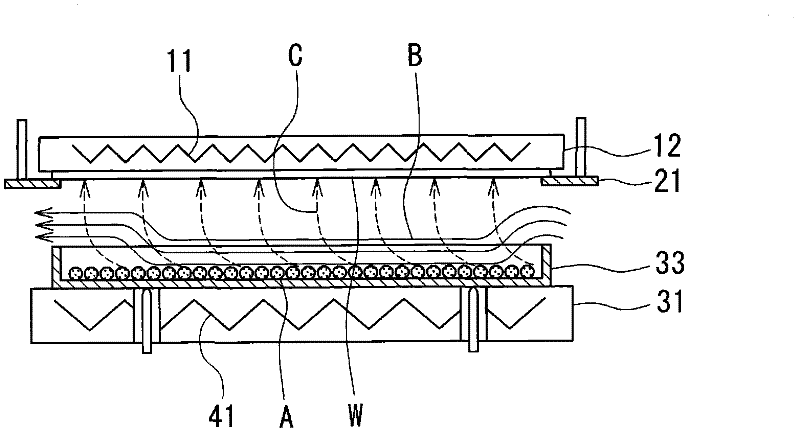

[0030] The film formation apparatus 100 according to the first embodiment of the present invention will be described. First, refer to figure 1 as well as figure 2 , the structure of the film forming apparatus 100 will be described. figure 1 It is a sectional view showing a schematic structure of the film forming apparatus 100 according to the first embodiment, figure 2It is a diagram showing a configuration example of its control system. This film forming apparatus 100 includes, as main configurations, a processing container 1 for accommodating a semiconductor wafer (hereinafter referred to as "wafer W") as a substrate to be processed; a substrate heater 11 as a first heater; and a holding member 21 for holding the wafer W. ; the table 31 as a raw material supporting part; and the raw material heater 41 as a second heater. The film forming apparatus 100 further includes: an exhaust device 51 as an exhaust unit for maintaining the inside of the processing chamber 1 in a v...

no. 2 approach

[0084] Next, a second embodiment of the present invention will be described. Figure 9 It is a cross-sectional view showing a schematic configuration of the film forming apparatus 101 according to the second embodiment. In this embodiment, as means for heating the solid raw material A, a lamp heater is used. In addition, in the following description, the Figure 9 The characteristic structure of the film forming apparatus 101 will be described as the center. For the film forming apparatus 101 and figure 1 The same structures of the film forming apparatus 100 are denoted by the same symbols and descriptions thereof are omitted.

[0085] In the film forming apparatus 101 of the present embodiment, as a raw material support unit, for example, an annular movable member 121 that can be raised and lowered is provided, and the movable member 121 stands upright from the movable member 121 and comes into contact with the bottom surface of the raw material tray 33 to support the raw m...

no. 3 approach

[0094] Next, a third embodiment of the present invention will be described. Figure 11 It is a cross-sectional view showing a schematic configuration of the film formation apparatus 102 according to the third embodiment. In addition, in the following description, the Figure 11 The characteristic structure of the film forming device 102 will be described as the center. For the film forming device 102 and figure 1The same structures of the film forming apparatus 100 are denoted by the same symbols and descriptions thereof are omitted. In the film forming apparatus 102 of this embodiment, the wafer W is held by an electrostatic adsorption mechanism. An electrostatic chuck 151 serving as a substrate holder is embedded in the heat transfer plate 12 disposed in the upper portion of the processing chamber 1 . The electrostatic chuck 151 has a structure in which an unillustrated electrode layer is sandwiched between dielectric layers, and the electrode layer is connected to a DC p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com