Overhauling platform of breaker

A technology for overhauling platforms and circuit breakers, applied to switchgear, electrical components, etc., can solve problems such as difficulties, increase the time for overhaul, and promote the wear and tear of trolleys, so as to simplify the intermediate links of operation, enhance maintainability, and reduce work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

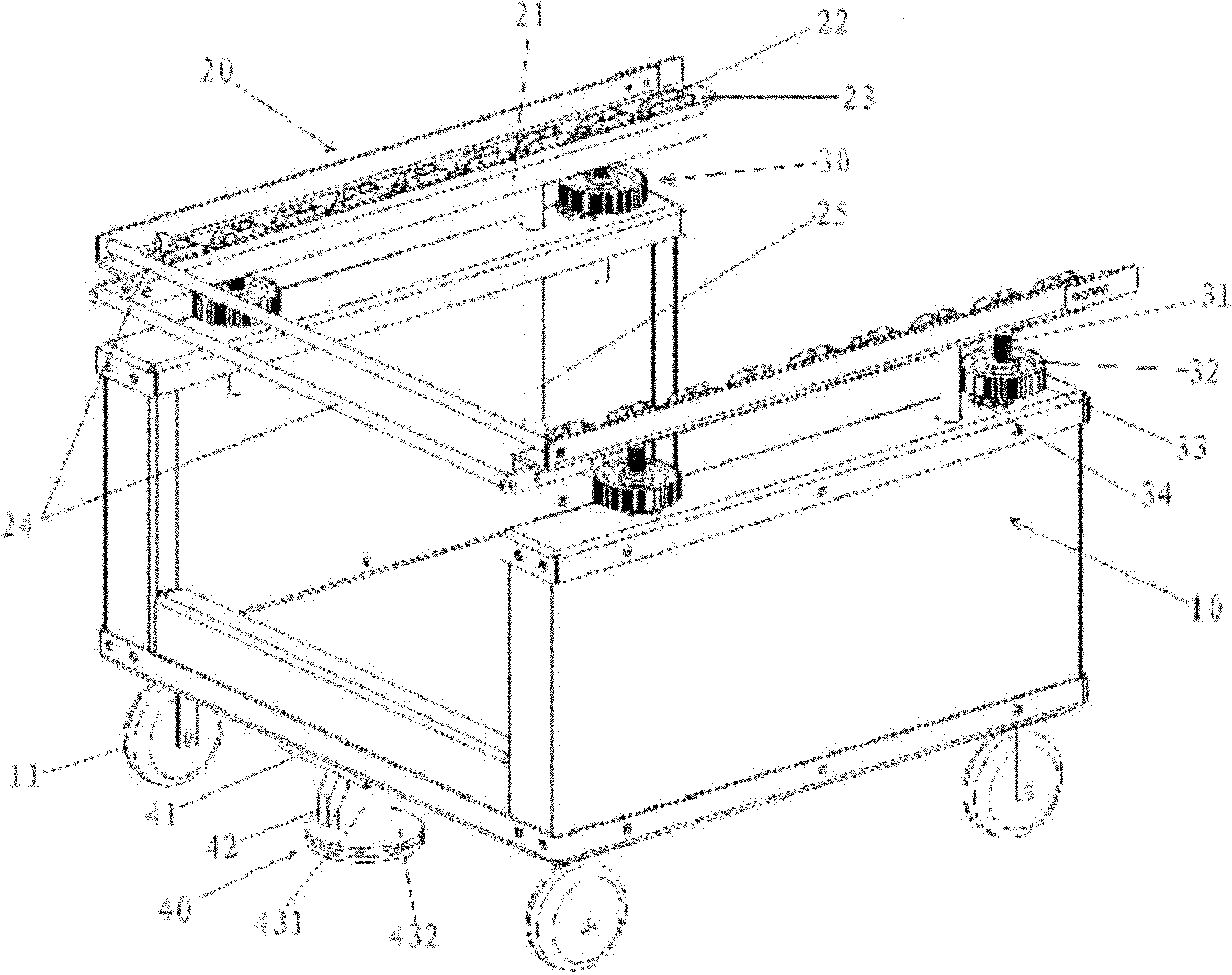

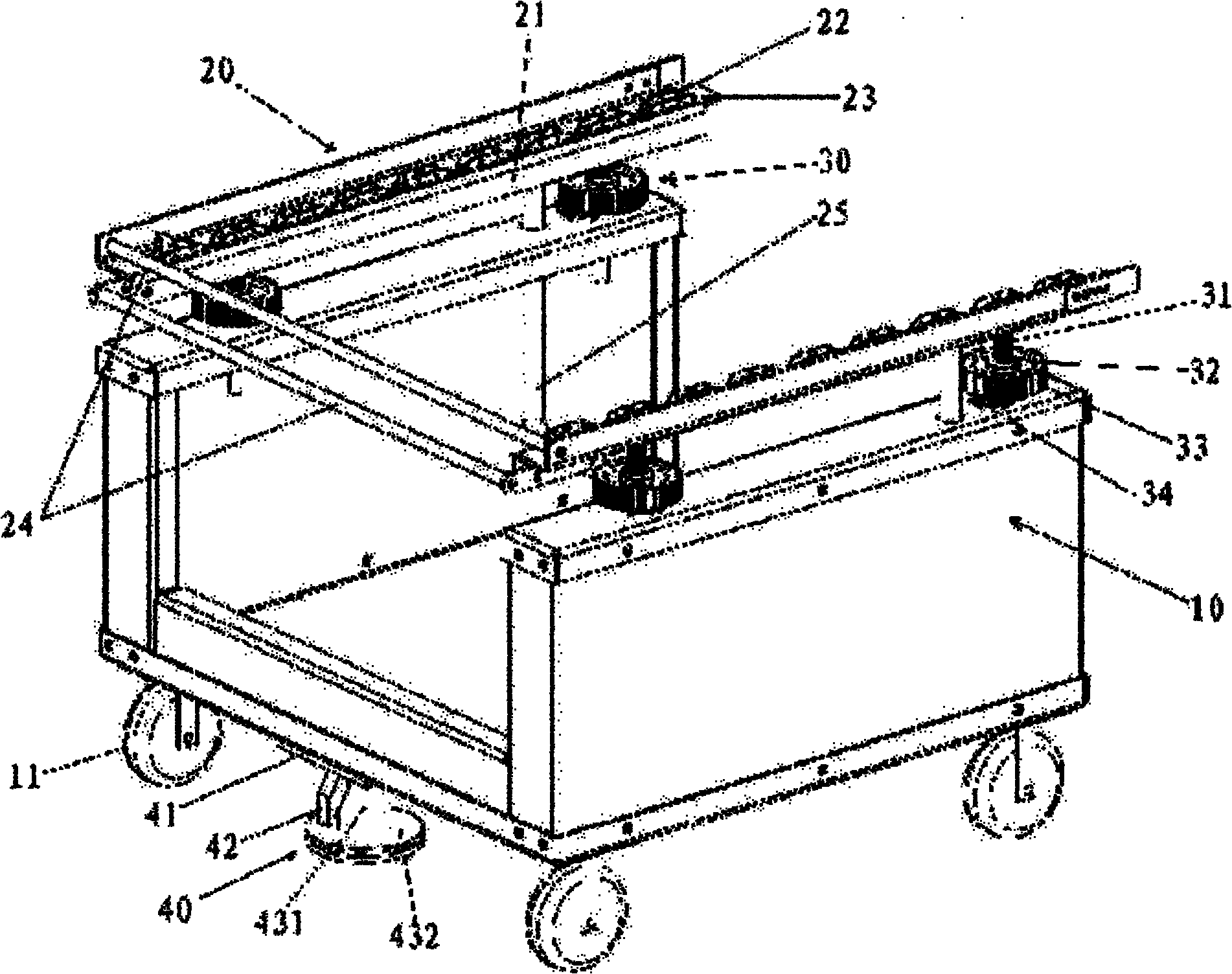

[0028] Such as figure 1 As shown, the present invention is a circuit breaker maintenance platform, which includes a transfer vehicle frame 10, a load guide rail 20, a lifting mechanism 30 and a braking structure 40, wherein,

[0029] The transfer vehicle frame 10 is a frame structure with one side opening, and the four corners of the bottom surface of the transfer vehicle frame 10 are respectively provided with a steering wheel 11;

[0030] The bearing guide rail 20 includes two fixed seats 21 symmetrically fixedly connected to the top surface of the transfer vehicle frame 10 by a support rod 25, and each fixed seat 21 surface is provided with a guide groove (not shown in the figure), and in each guide groove a There are several pulleys 22 arranged in letters, and one end of each fixed seat 21 is provided with a guide 23, and the length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com