Gas-solid-liquid separation and purification system for agricultural and forestry biomass material gasified gas

A biomass material, gas-solid-liquid separation technology, applied in the separation method, dispersed particle separation, steam condensation, etc., can solve the problems of affecting heat transfer, poor condensation effect, affecting the quality of gas supply and power generation, etc., to achieve a scientific system composition , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

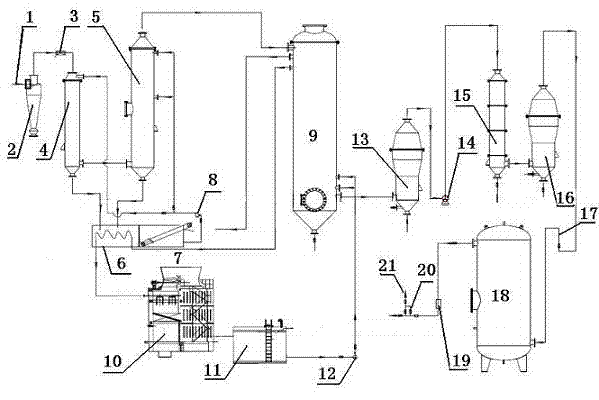

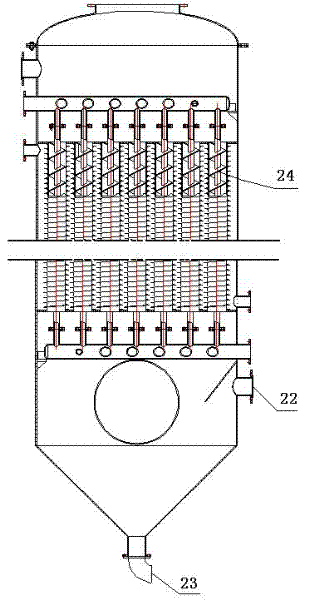

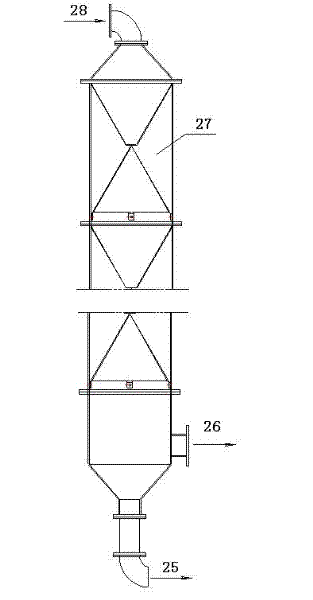

[0010] Control attached figure 1 , its structure includes a dust removal system, a spray circulation system, a cooling circulation system, and a combustible gas purification system, in which the gas at 250-500 °C output from the gasifier in the dust removal system is connected to the cyclone separator through the outlet of the gas input pipe 1 2 (dust removal), a gravity check valve 3 is set between the cyclone separator 2 and the spray tower 4 to prevent the gas from detonating and the spray liquid from flowing backward.

[0011] The upper part of the spray tower 4 and the washing tower 5 is equipped with an atomizing spray head, so that the gas can be fully sprayed and cleaned when passing through, to cool down and remove heavy tar, and the outlets at the bottom of the spray tower 4 and the washing tower 5 are connected to The cooling circulation tank 6 takes away the heat of the spray circulation fluid through the heat exchange coil in the cooling circulation tank 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com