Method for controlling secondary cooling water spraying width during continuous casting of plate blank

A technology of width control and slab continuous casting, which is applied in the field of secondary cooling water spray width control to achieve the effects of preventing corner overcooling, accurate control of secondary cooling water spray width, and avoiding corner cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

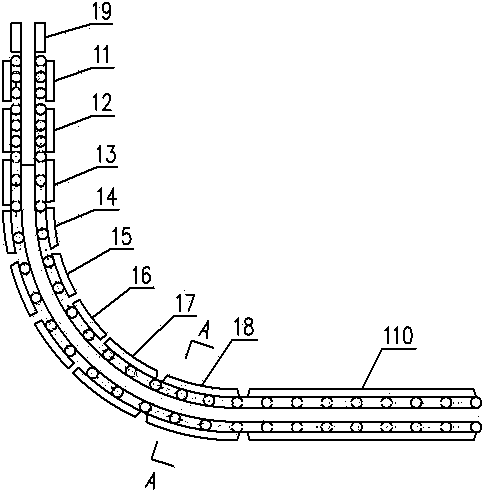

[0030] figure 1 Shown is a schematic diagram of the existing slab continuous casting machine with secondary cooling water spray width control function, the general structure includes: each secondary cooling section before the straightening area (the figure contains 8 in total, the actual situation can be adjusted according to the actual situation, in order Numbers are 11 to 18, wherein 18 is the second cooling section of the straightening zone); 19 is the crystallizer; 110 is the horizontal section;

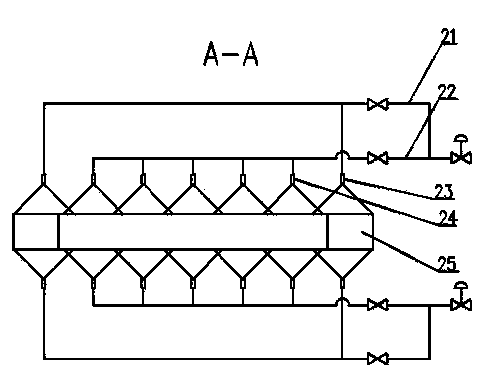

[0031] figure 2 for figure 1 In the sectional view of A-A, there is an edge nozzle circuit on both sides of each secondary cooling section. Wherein 21 is a side nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com