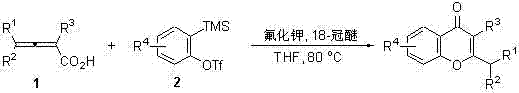

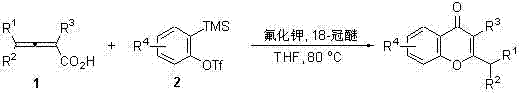

Method for synthesizing multi-substituted chromone compound

A chromone compound, multi-substitution technology, applied in the direction of organic chemistry, etc., can solve the problems of restricting the synthesis and development of multi-substitution chromone compounds, difficult to prepare, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add potassium fluoride (0.0466 g, 0.8 mmol) and 18-crown ether (0.2118 g, 0.8 mmol) to the sealed tube in the glove box; then add 2-methyl-4-phenyl- 2,3-Butadienoic acid (0.0700 g, 0.4 mmol), 2-(trimethylsilyl)phenyl triflate (0.15 mL, d = 1.229 g / ml, 0.1844 g, 0.4 mmol) and tetrahydrofuran (4 ml), after the addition was completed, the tube was sealed and placed in an oil bath at 80 degrees Celsius; after reacting at 80 degrees Celsius for 12 hours, it was returned to room temperature, and the silica gel was short Column filtration, diethyl ether washing; spin drying and flash column chromatography gave 0.0888 g of 3-benzyl-3-methylchromone, the yield was 88%, the product was solid, m.p. 125.7-126.2 o C (hexane / ethyl acetate).

[0026] 1 H NMR (300 MHz, CDCl 3 ) δ 8.19 (dd, J 1 = 8.1 Hz, J 2 = 1.5 Hz, 1 H, Ar-H), 7.64-7.52 (m, 1 H, Ar-H), 7.40-7.20 (m, 7 H, Ar-H), 4.05 (s, 2 H, PhCH 2 ), 2.15 (s, 3 H, CH 3 ); 13 C NMR (CDCl 3 , 75 MHz) δ 178.1, 162.7, 155...

Embodiment 2

[0029] According to the method described in Example 1, the difference is that the amount of reagent used is: potassium fluoride (0.698 g, 12 mmol), 18-crown ether (3.1690 g, 12 mmol), 2-methyl-4-benzene 2,3-butadienoic acid (1.048 g, 6 mmol), 2-(trimethylsilyl)phenyl triflate (2.25 mL, d = 1.229 g / ml, 2.7653 g, 9 mmol), tetrahydrofuran (60 ml), to give 1.3648 g of 3-benzyl-3-methylchromone, yield 91%.

[0030]

Embodiment 3

[0032] According to the method described in Example 1, the difference is that the substrates and reagents used are: potassium fluoride (0.0468 g, 0.8 mmol), 18-crown ether (0.2112 g, 0.8 mmol), 2-methyl-4 -p-methylphenyl-2,3-butadienoic acid (0.0752 g, 0.4 mmol), 2-(trimethylsilyl)phenyl triflate (0.15 mL, d = 1.229 g / ml, 0.1844 g, 0.6 mmol), 0.0955 g of 3-methyl-2-p-methylbenzochromone was obtained, the yield was 90%, and the product was solid, m.p. 102.9-103.3 o C (hexane / ethyl acetate).

[0033] 1 H NMR (300 MHz, CDCl 3 ) δ 8.16 (dd, J 1 = 7.8 Hz, J 2 = 1.5 Hz, 1 H, Ar-H), 7.63-7.53 (m, 1 H, Ar-H), 7.40-7.28 (m, 2 H, Ar-H), 7.17 (d, J = 8.1 Hz, 2 H, Ar-H), 7.12 (d, J = 8.1 Hz, 2 H, Ar-H), 4.00 (s, 2 H, ArCH 2 ), 2.31 (s, 3 H, CH 3 ), 2.15 (s, 3 H, CH 3 ); 13 C NMR (CDCl 3 , 75 MHz) δ 178.3, 163.1, 155.9, 136.6, 133.0, 132.8, 129.4, 128.3, 125.7, 124.5, 122.5, 117.7, 117.3, 37.8, 21.0, 10.1; MS (EI) m / z (%) 264 (M + , 8.78), 61 (100); IR (KBr, cm -1) 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com