Preparation method of magnesium-alloy electron backscatter diffraction sample (EBSD) and special electrolyte thereof

An electron backscattering and sample preparation technology, applied in the preparation of test samples, electrolysis process, electrolysis components, etc., can solve the problems of high price and high cost, and achieve the effect of practical cost, cost reduction and high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the magnesium alloy electron backscatter diffraction sample of the present invention comprises the following steps:

[0030] (1) Electrolyte preparation, put perchloric acid and alcohol into the beaker according to the volume ratio of 1:9 and stir, the minimum volume of the electrolyte can satisfy the electrolysis sample can be fully immersed;

[0031] In this embodiment, the purity of perchloric acid is 70.0-72.0%wt, and the purity of alcohol is ≥99.7%wt.

[0032] (2) Sample coating, cover the part of the sample that does not need electrolysis with nail polish (conventional nail polish is acceptable, the active ingredients are toluene, butyl acetate, formaldehyde resin and ethyl acetate, etc.), the sample The part connected to the anode must not be covered;

[0033] (3) Electrolysis, pour liquid nitrogen into a beaker filled with electrolyte until the temperature of the electrolyte is lower than -20°C, hang the AZ31 magnesium alloy sample on ...

Embodiment 2

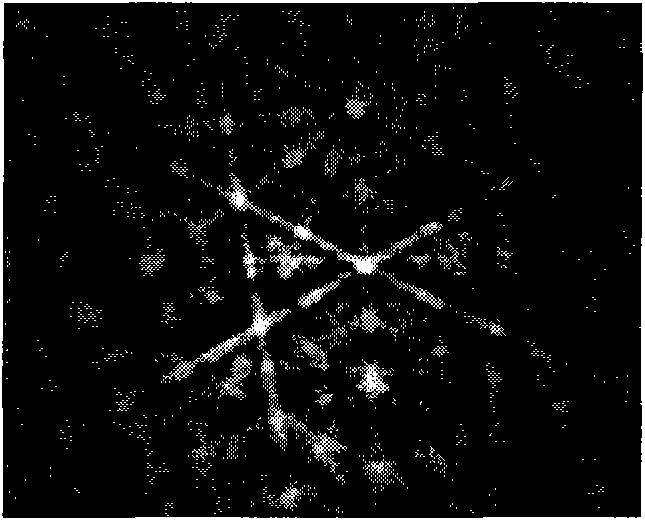

[0038] Adopt exactly the same step and technical requirement as in embodiment 1, prepared AZ61 magnesium alloy electron backscatter diffraction (EBSD) sample, image 3 It is the Kikuchi band diagram of the prepared AZ61 EBSD sample. The Kikuchi band in the picture is clearly visible, meeting the requirements of the EBSD experiment.

Embodiment 3

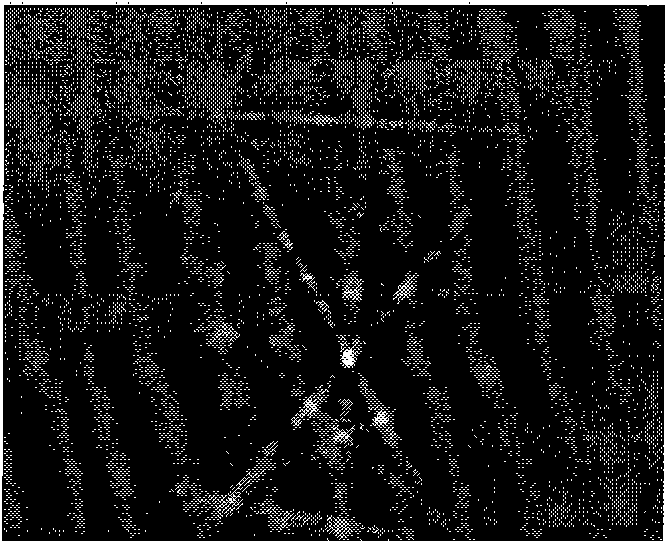

[0040] Adopt exactly the same step and technical requirement as in embodiment 1, prepared AZ80 magnesium alloy electron backscatter diffraction (EBSD) sample, Figure 4 It is the Kikuchi band diagram of the prepared AZ80 EBSD sample. The Kikuchi band in the picture is relatively clear, which meets the requirements of the EBSD experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com