Oil-rail pressure closed-loop control based direct jetting method and system of combustion engine

A technology of oil rail pressure and closed-loop control, which is used in electrical control, charging system, engine control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings.

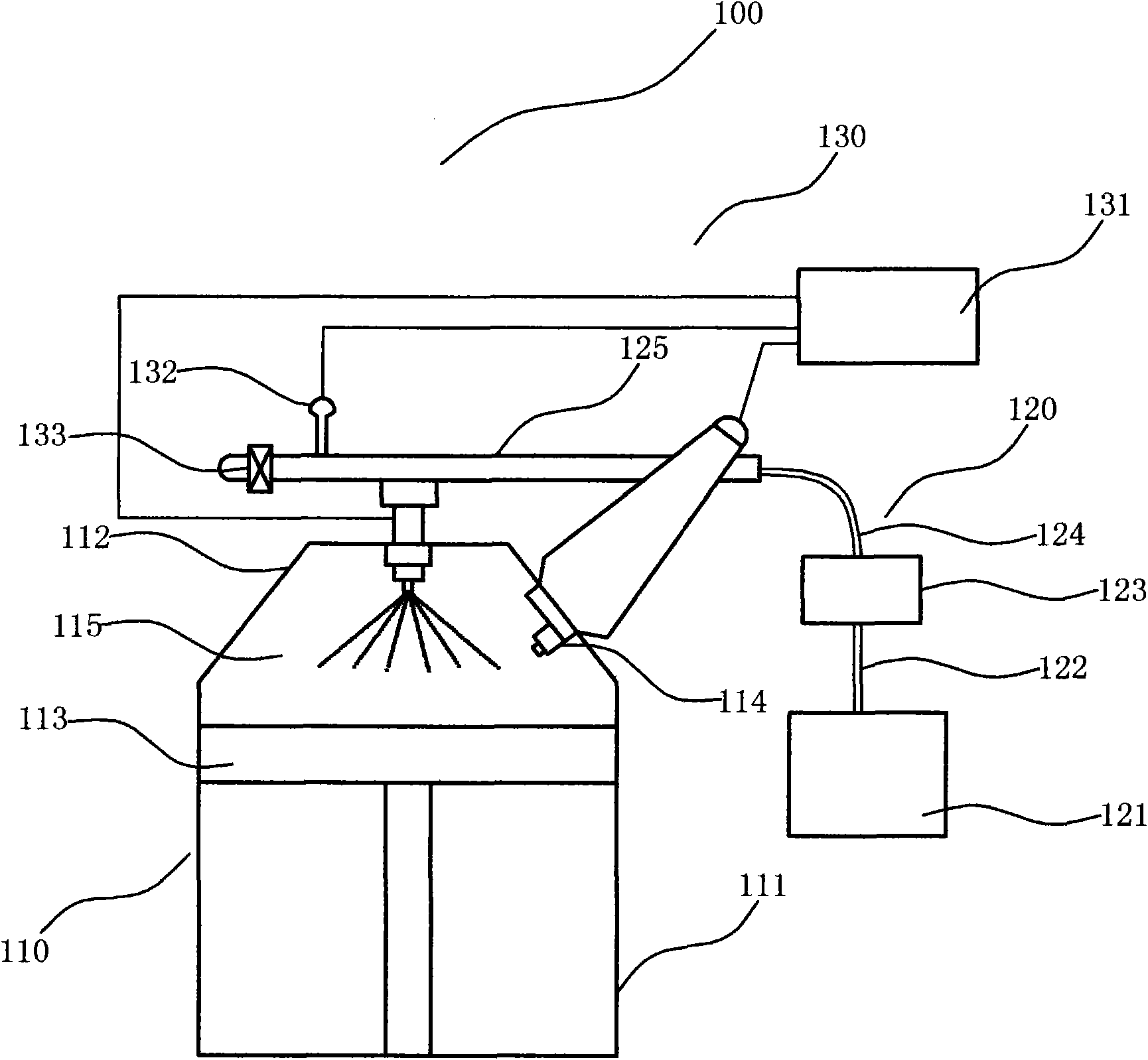

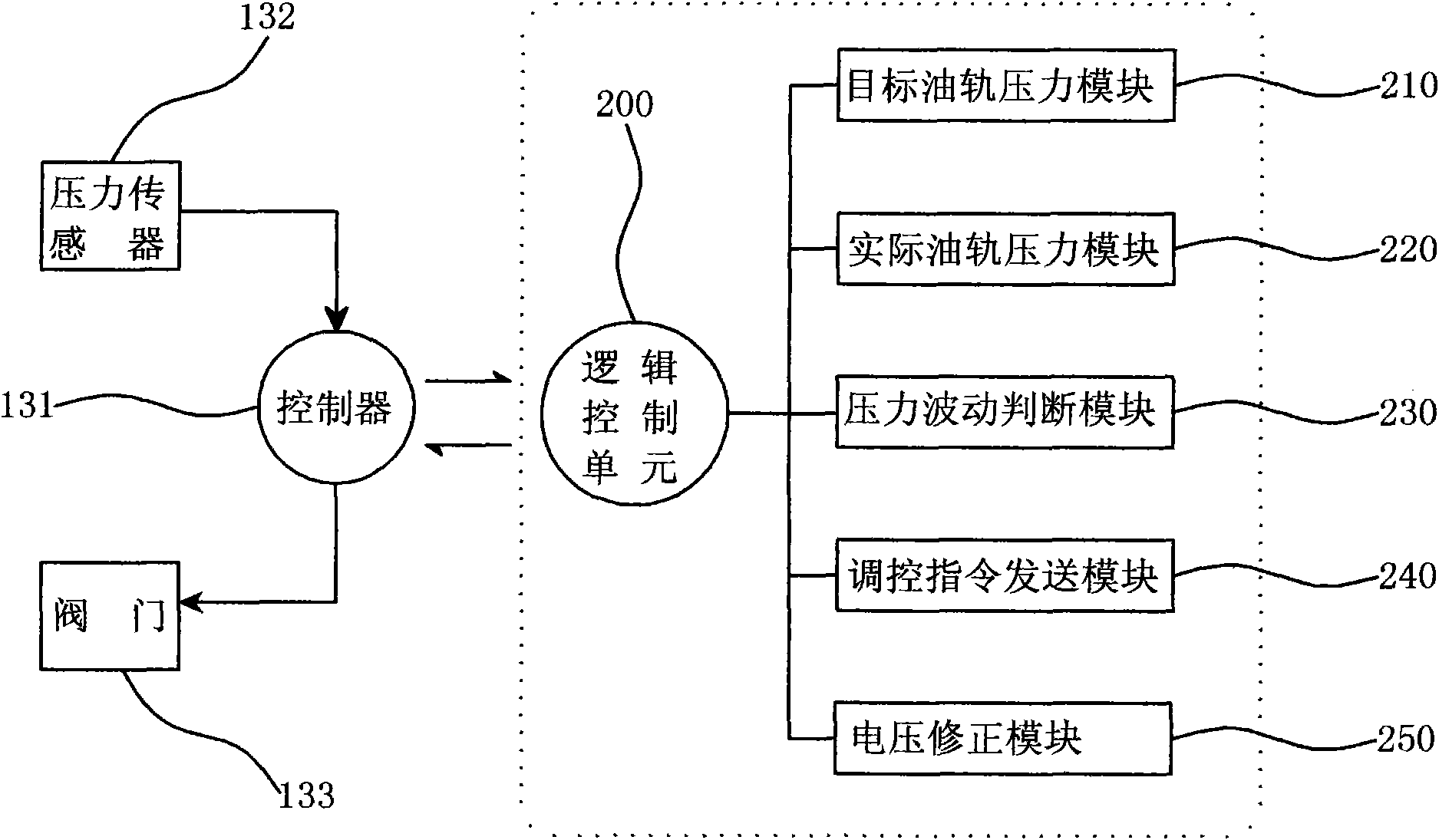

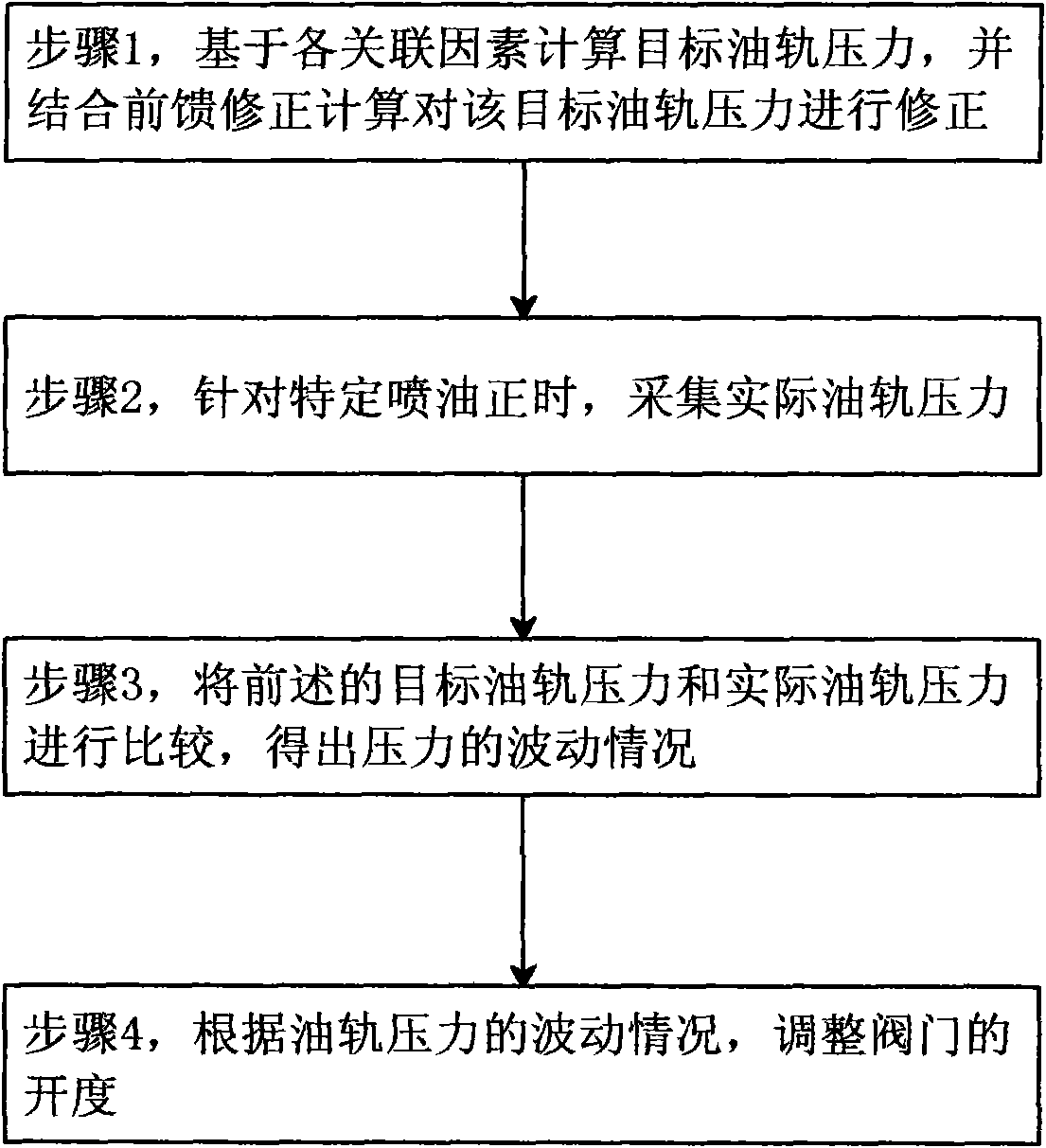

[0031] First, refer to figure 1 The structural schematic diagram of the system described in the present invention shown, figure 2 A schematic block diagram of the system according to the present invention is shown, and image 3 The flow chart of pressure control using the present invention is shown to describe the present invention as a whole.

[0032] Such as figure 1 As shown, the gasoline direct injection system based on the closed-loop control of fuel rail pressure is set up corresponding to the hardware structure shown by reference numeral 100 as a whole. It includes an internal combustion engine 110 , a fuel system 120 and a control system 130 , where the fuel system 120 is controlled by the control system 130 to provide fuel including gasoline to the internal combustion engine 110 . By way of example and not limitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com