Welding line radiographic-inspection detection data analysis and photo identification system

A technology of radiographic flaw detection and detection data, which is applied in the field of high-end equipment parts, can solve the problems of low efficiency, low consistency standard, time-consuming and laborious analysis, etc., and achieve the effect of high efficiency and high consistency standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

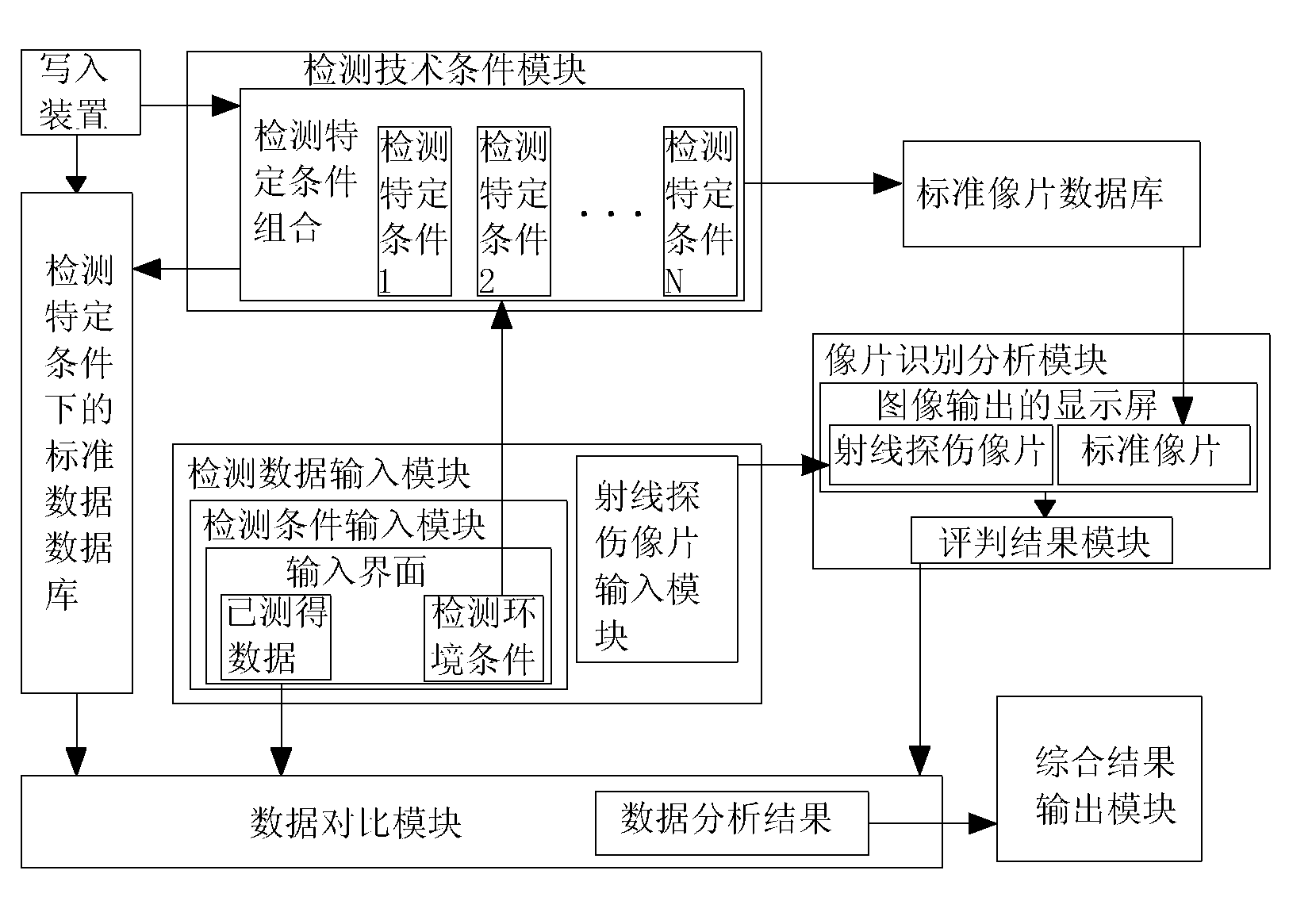

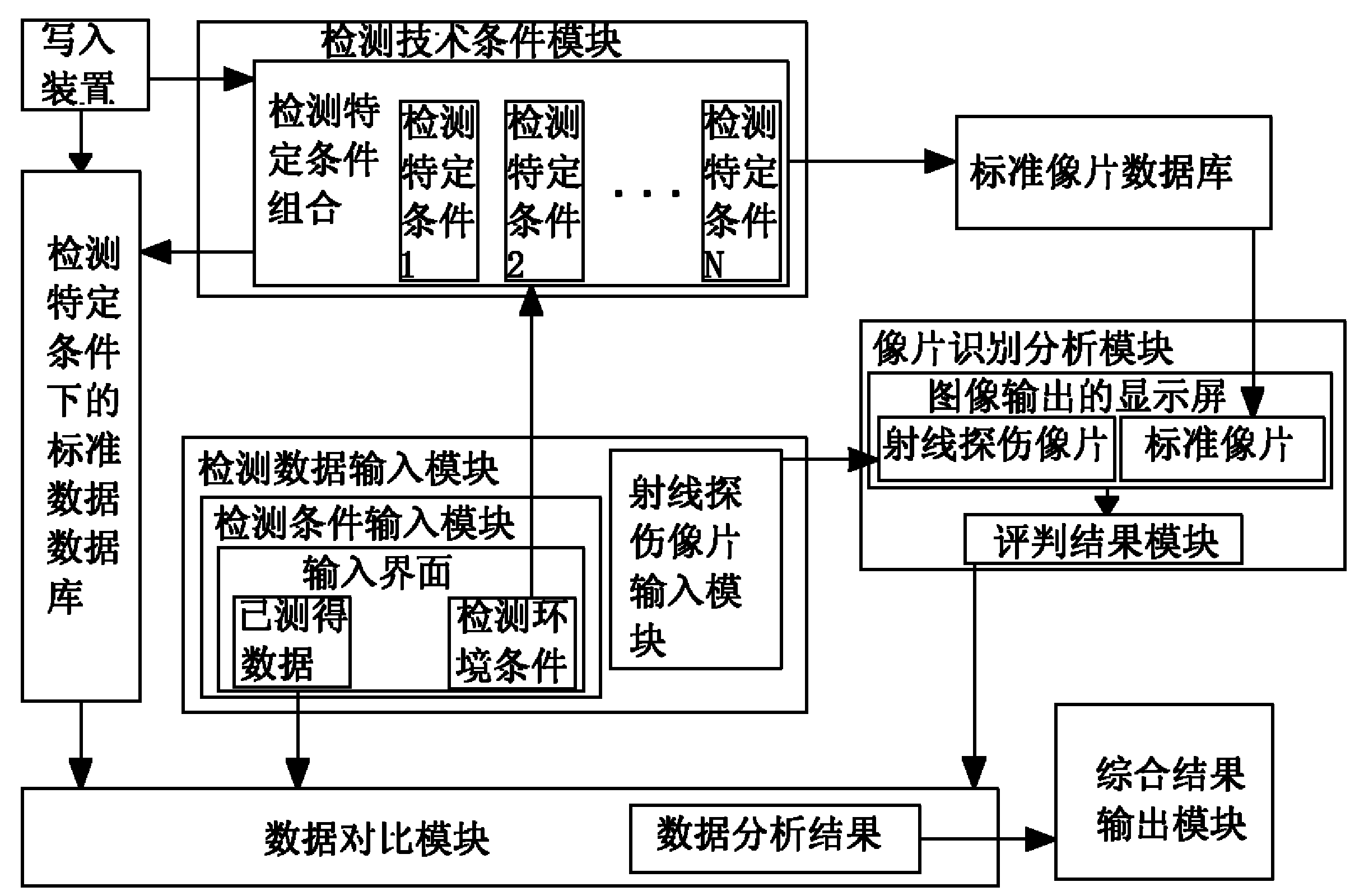

[0010] See figure 1 , which includes a detection technical condition module, a detection data input module, a standard photo database, a photo recognition and analysis module, a comprehensive result output module, a standard data database under specific detection conditions, a data comparison module, and each photo in the standard photo database Standard photos are associated with specific detection conditions in the detection technical condition module, which stores various specific detection conditions corresponding to each weld; the detection data input module includes a detection condition input module, a radiographic flaw detection photo input module, and a detection condition The input module is used to enter the data under the specific detection conditions of the weld, including: the measured data, the detection environment conditions, the data entered in the detection environment conditions automatically matches the detection specific conditions in the detection technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com