Driver module and electronic device

A technology for driving modules and driven bodies, which can be applied to instruments, other household appliances, optical components, etc., can solve the problems of high manufacturing costs, damage, peeling, etc., so as to reduce manufacturing costs, seek manufacturing costs, and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

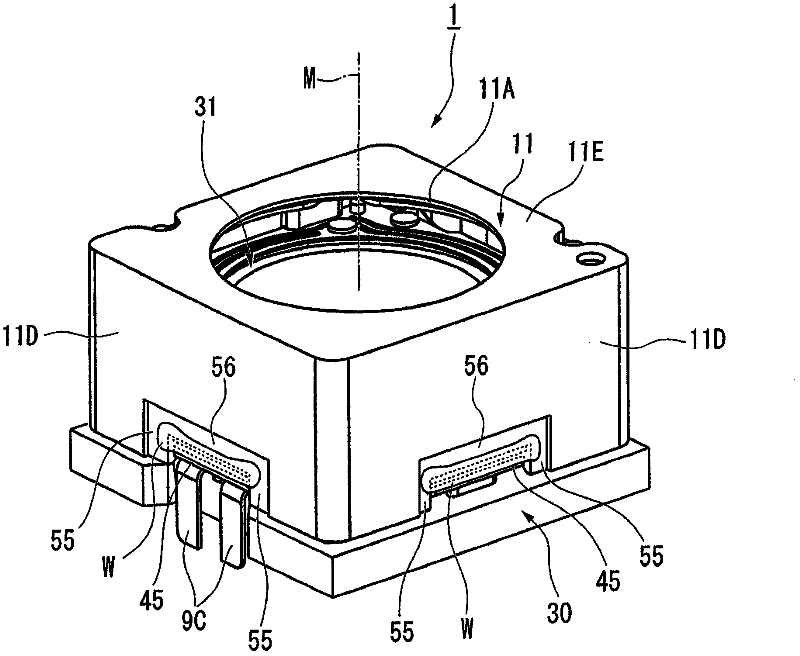

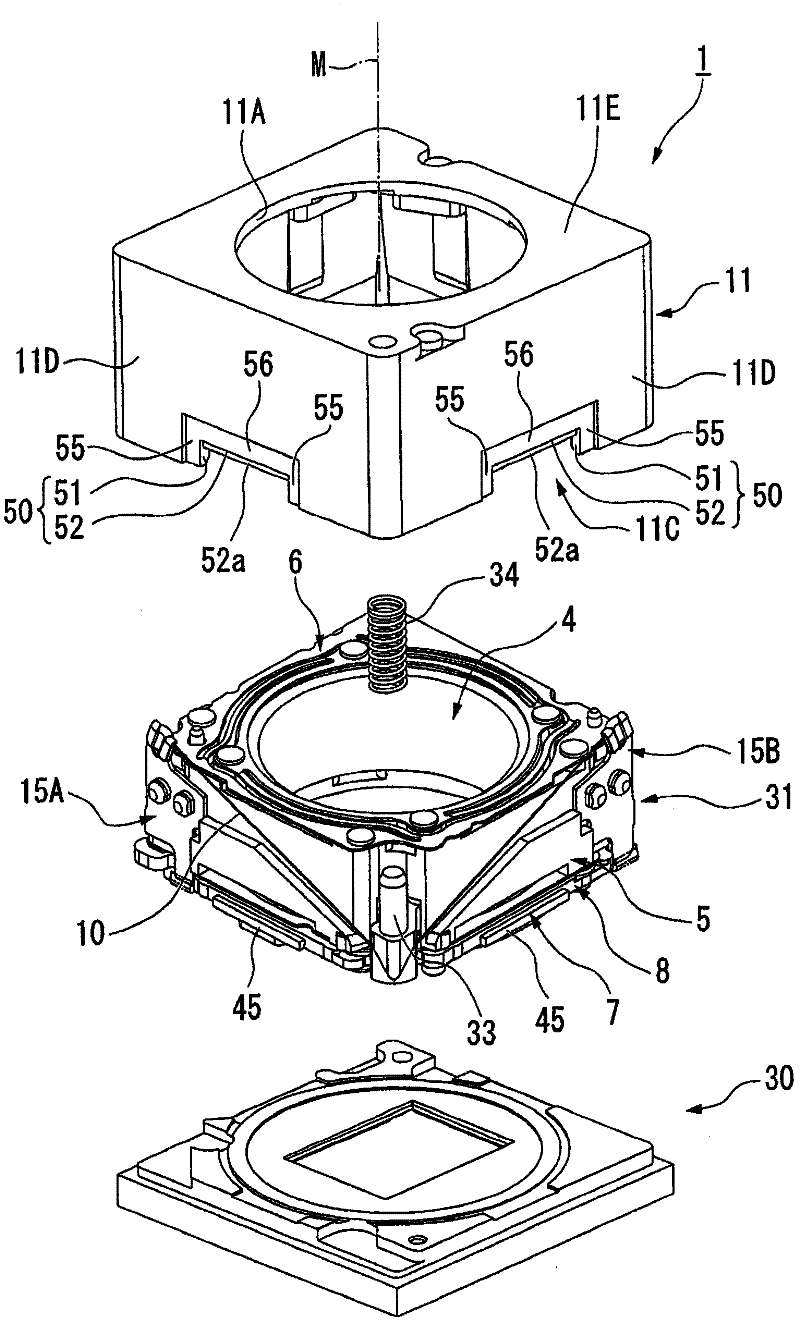

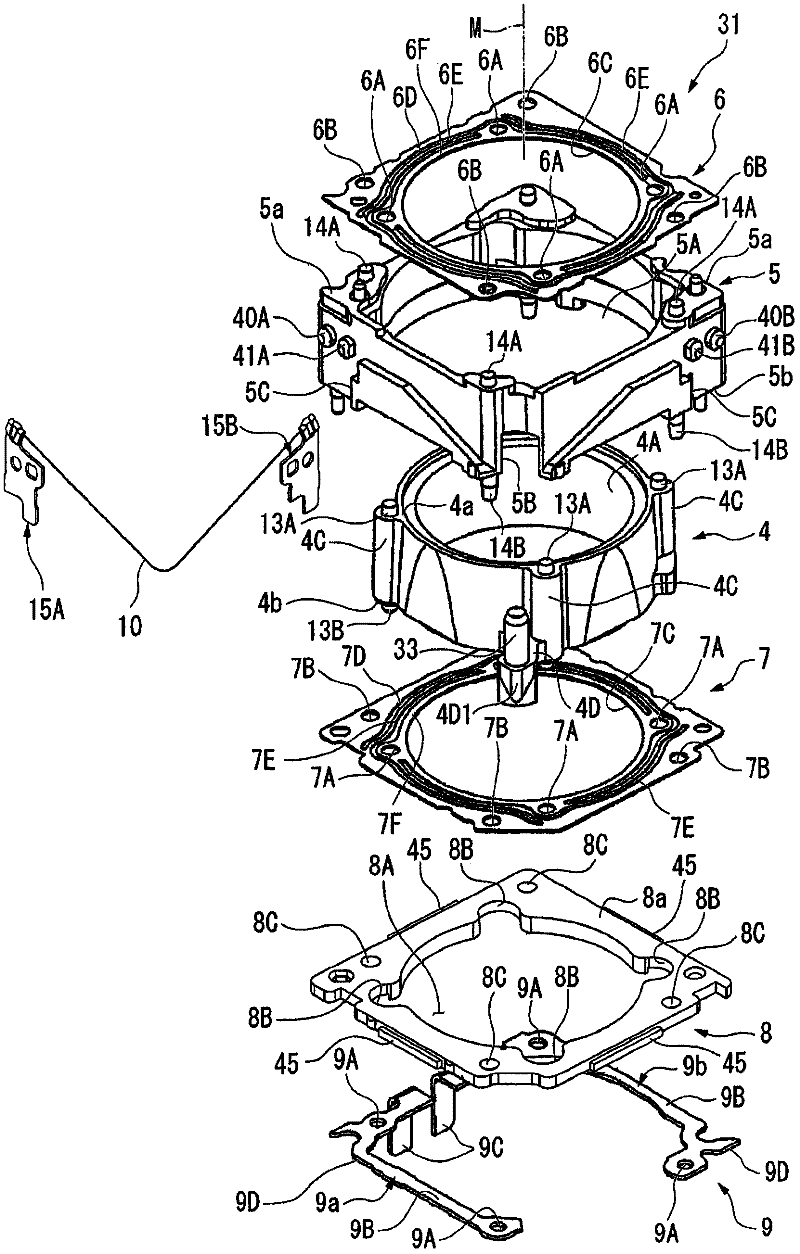

[0074] (drive module)

[0075] Below, refer to Figure 1 to Figure 16 , an embodiment of the drive module according to the present invention will be described. In addition, in this embodiment, a driving module that drives an imaging lens unit in a camera will be described as an example. In addition, as an example of an actuator that drives a lens unit, a case where a shape memory alloy wire is used will be exemplified.

[0076] In addition, in this embodiment, in some drawings, in order to make it easier to see, for example, the Figure 5 The shown lens unit 12 and other components are shown in the figure.

[0077] in addition, figure 1 Symbol M in the diagrams is a virtual axis line of the driving module 1 that coincides with the optical axis of the lens unit 12 , and indicates the driving direction of the lens frame 4 described later. Hereinafter, in the description of each disassembled component, the position or direction may be referred to based on the positional rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com