Manufacturing method of diode and automatic output device of diode

A technology of automatic conveying device and manufacturing method, which is used in transportation and packaging, semiconductor/solid-state device manufacturing, conveyor objects, etc., can solve the problem of long exposure of the die to the air, poor electrical properties of finished products, and many intermediate links, etc. problems, to achieve the effects of conventional electrical consistency and high temperature performance improvement, high temperature leakage current reduction, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

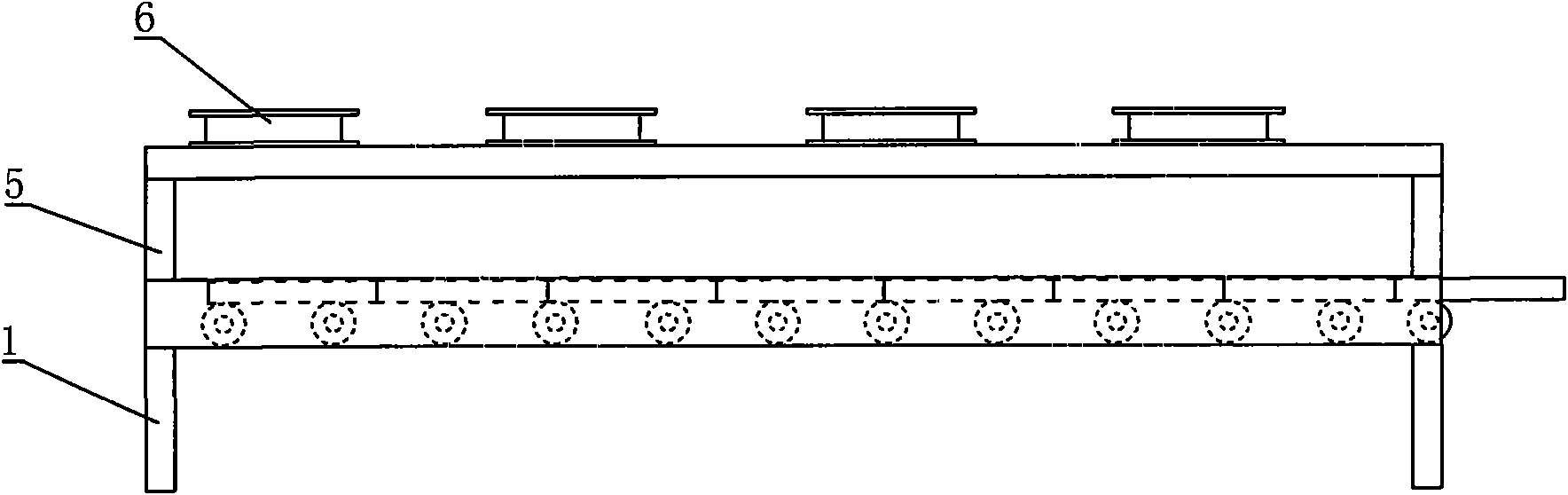

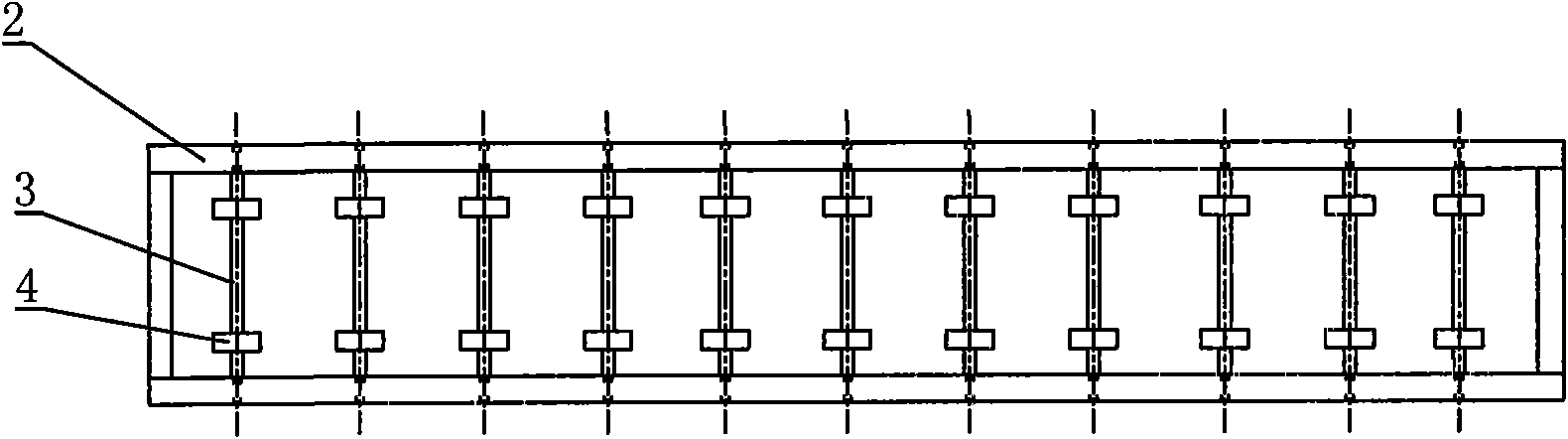

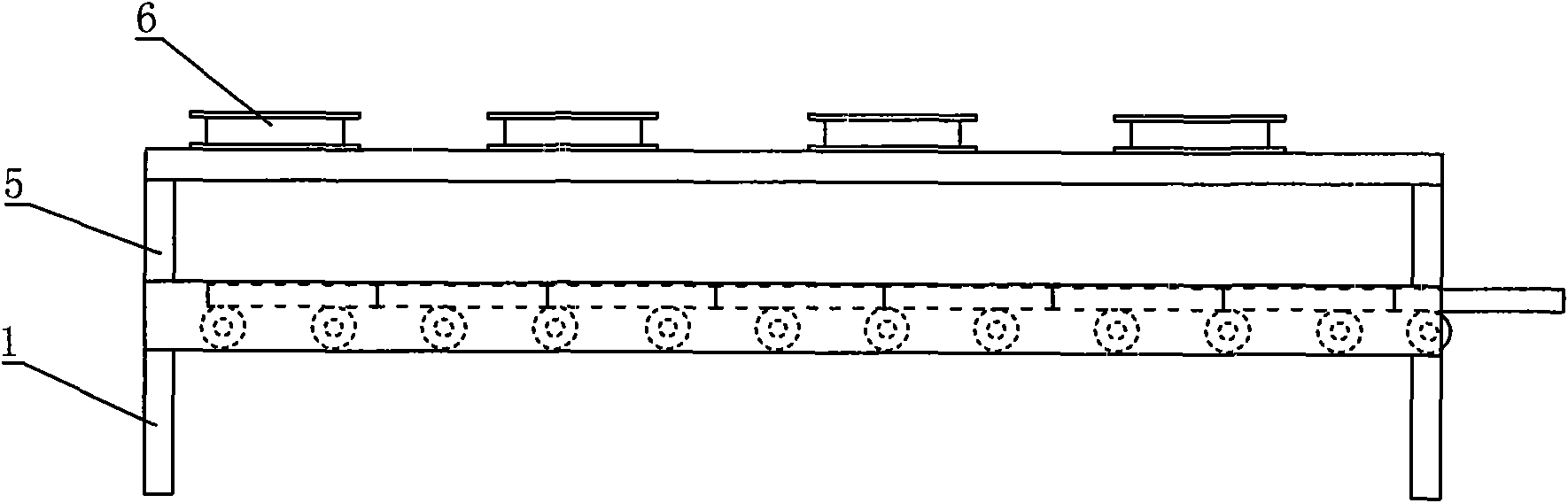

Image

Examples

Embodiment Construction

[0013] The present invention is specifically made of the following steps:

[0014] A. Loading: according to the routine, put the lead wires in the stone and wooden boat to the rear and install the lower layer of solder and die, and then install the upper layer of solder and press it tightly.

[0015] B. Welding: Send the stone wooden boat with the soldering piece into a furnace with a temperature above 300°C and the furnace cavity is filled with nitrogen, and bake at a high temperature in this way for more than 12 minutes to ensure that the peak temperature in the furnace is 360-370°C. After soldering, it comes out of the oven.

[0016] C. Pickling and combing the semi-finished diodes after welding as usual.

[0017] D. Pre-baking: Control the initial temperature in the furnace at 100°C, then raise the temperature until the peak temperature is 203°C-216°C to pre-bake the product; during pre-baking, the time in the furnace when the temperature is greater than 150°C is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com