Double catalyst layer membrane electrode of direct methanol fuel cell and preparation method thereof

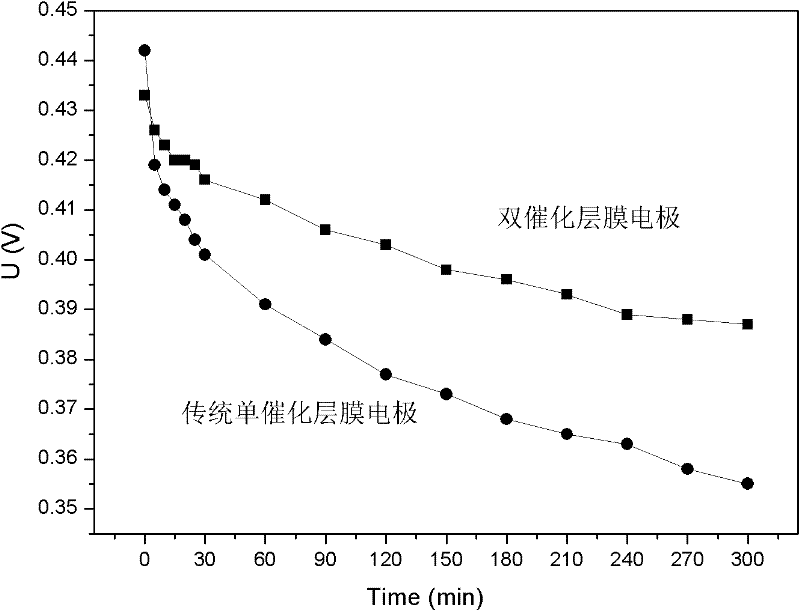

A methanol fuel cell, double catalytic layer technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of improving operation stability and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] A double-catalyzed membrane electrode for a direct methanol fuel cell, comprising a cathode diffusion layer, an anode diffusion layer, a cathode catalyst layer, an anode catalyst layer, a proton exchange membrane, a cathode "catalytic glue" layer and an anode "catalytic glue" layer, wherein the proton One side of the exchange membrane is the cathode "catalytic glue" layer, the cathode catalytic layer and the cathode diffusion layer in turn, and the other side is the anode "catalytic glue" layer, the anode catalytic layer and the anode diffusion layer in turn. The anode "catalytic glue" layer contains 60 %wt% Nafion and 40wt% catalyst, the cathode "catalytic glue" layer contains 70%wt% Nafion and 30wt% catalyst. The anode catalyst layer contains 10wt% Nafion and 90wt% catalyst, the cathode catalyst layer contains 30wt% Nafion and 70wt% catalyst, the catalyst used in the anode catalyst layer and the anode "catalytic glue" layer is a PtRu black catalyst, The catalyst used ...

Embodiment 2

[0032] The direct methanol fuel cell double-catalyzed membrane electrode includes a cathode diffusion layer, an anode diffusion layer, a cathode catalyst layer, an anode catalyst layer, a proton exchange membrane, a cathode "catalytic glue" layer and an anode "catalytic glue" layer, wherein the proton exchange membrane One side is the cathode "catalytic glue" layer, the cathode catalytic layer and the cathode diffusion layer in turn, and the other side is the anode "catalytic glue" layer, the anode catalytic layer and the anode diffusion layer in turn, and the anode "catalytic glue" layer contains 70%wt% Nafion and 30wt% catalyst, the cathode "catalytic glue" layer contains 80%wt% Nafion and 20wt% catalyst. The anode catalyst layer contains 15wt% Nafion and 85wt% catalyst, the cathode catalyst layer contains 35wt% Nafion and 65wt% catalyst, the catalyst used in the anode catalyst layer and the anode "catalytic glue" layer is a PtRu black catalyst, The catalyst used in the cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com