Microbial fuel cell air cathode easy to perform scale preparation and preparation method thereof

An air cathode, fuel cell technology, applied in biochemical fuel cells, battery electrodes, electrical components, etc., can solve the problems of low conductivity of the catalyst layer, less catalyst coating, affecting electrode performance, etc. Simple process and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

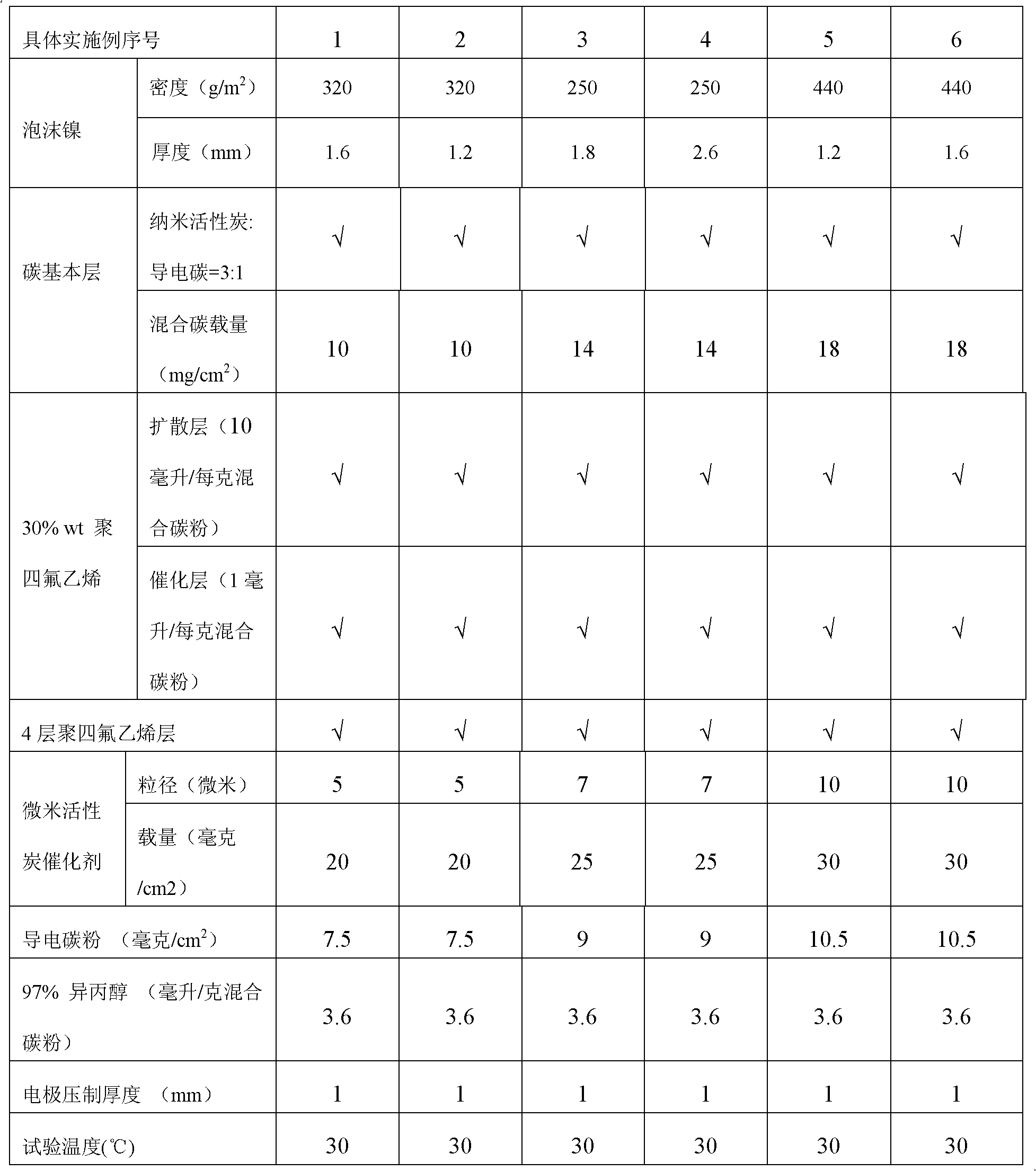

[0031] Air cathode preparation method among the present invention comprises the steps:

[0032] (1) Make a mixed carbon base layer:

[0033] Nano activated carbon powder and conductive carbon powder (F-900) are mixed by weight 3: 1, and then added into a polytetrafluoroethylene emulsion with a concentration of 30%wt and mixed into a paste, the ratio of adding is 10% per gram of mixed carbon powder ml of PTFE emulsion; the paste mixture is applied to one side of the nickel foam, and the coating amount of the mixed carbon powder is 14mg / cm 2 ; The nickel foam coated with carbon powder was heated at 370°C for 15 minutes, then taken out and cooled to room temperature;

[0034] (2) Make the polytetrafluoroethylene layer:

[0035] On the surface of the mixed carbon base layer made in step (1), uniformly coat one deck of 60%wt polytetrafluoroethylene emulsion and heat at 370°C for 15 minutes; repeat this step several times to form a multilayer polytetrafluoroethylene emulsion on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com