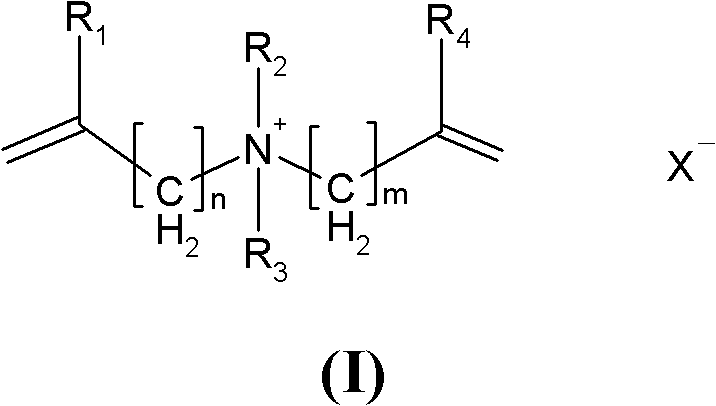

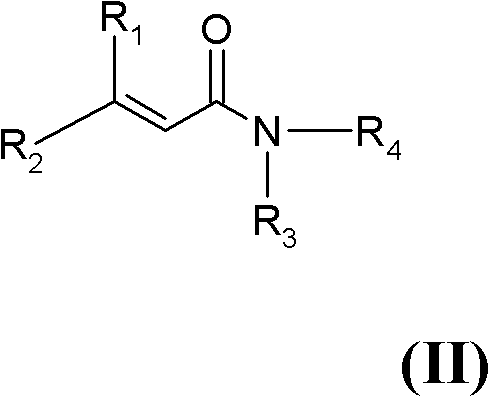

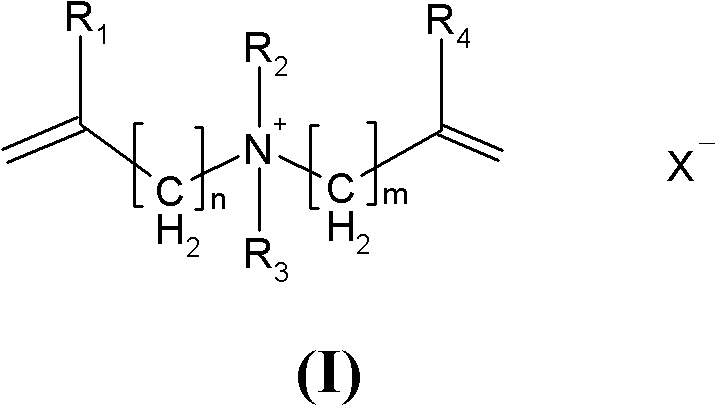

Fast drying ampholytic polymers for cleaning compositions

A technology of hard surface cleaners and terpolymers, applied in detergent compositions, organic detergent compositions, cationic surface active compounds, etc., which can solve the problems of slow drainage of water film and increased time required for surface drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] The 1 L reactor was purged with nitrogen. An initial charge of 15.5 g DADMAC (65.9%) solution, 1.3 g N,N-dimethylacrylamide, 40 mg acrylic acid (99%) solution, 1.5 g NaEDTA (10%) solution and 250 g deionized water was added to the reactor. The pH of the reaction mixture was adjusted to about 4.0 + / - 0.2 with HCl (5%) solution. The reaction was stirred at 210 rpm and heated to 100°C. A monomer charge was prepared from 6.7 g DADMAC (65.9%) solution, 54 g N,N-dimethylacrylamide, 3.25 g acrylic acid (99%) solution, 70 mg thioglycolic acid and 110 g deionized water. The pH of the feed solution was adjusted to about 4.0 + / - 0.2 with NaOH (10%) solution. Initially 5 ml of the monomer feed was added to the reactant mixture. Initiator (ammonium persulfate, 0.2 g in 20 ml of water) was introduced at a rate of 0.22 ml / min while the remainder of the monomer feed was added over 60 min. After completion of the monomer feed, the container containing the monomer feed was rinsed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com