Fuzzy control method for nonlinear precise forging press

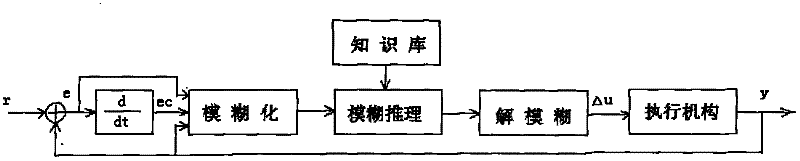

A technology of fuzzy control and forging press, which is applied in the driving device of forging press, adaptive control, general control system, etc., and can solve problems such as difficult modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

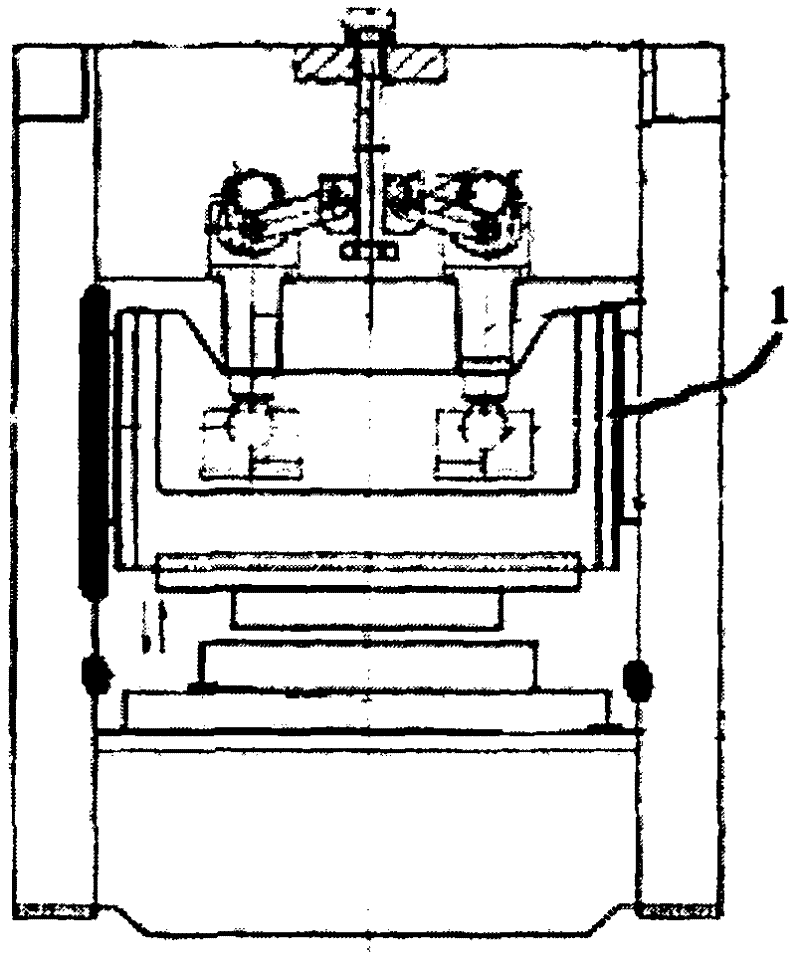

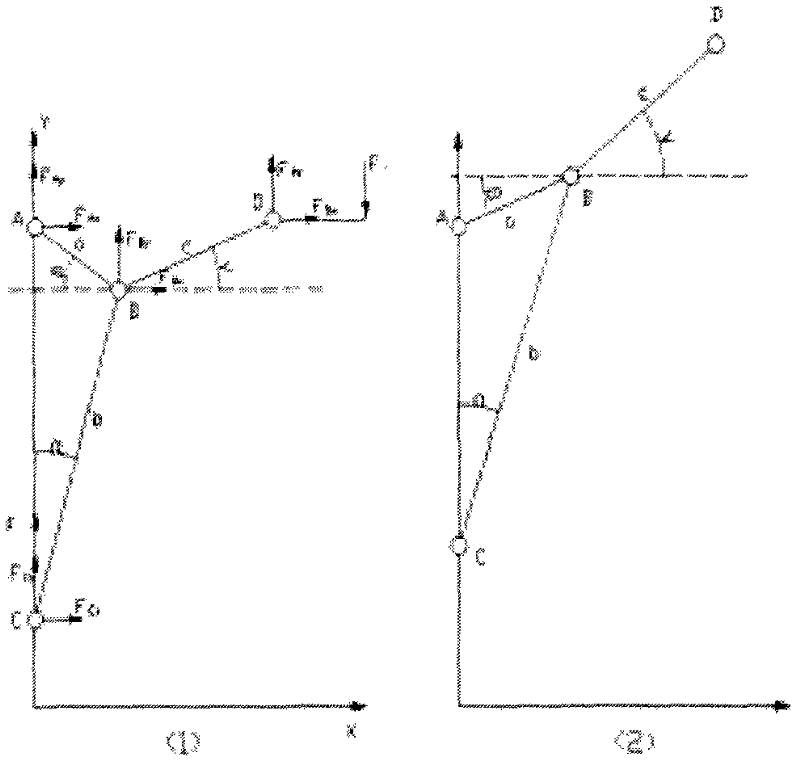

[0022] Such as figure 1 As shown, the precision forging press that the present invention relates to is made of fuselage, low-speed high-torque AC servo motor, synchronous gear, ball screw, ball spline, drive slider, balance cylinder, short connecting rod, crankshaft, long connecting rod, slide Block 1 and so on. The working principle of the forging press is: the controller controls the rotation angle of the servo motor according to the time-position key point of the slider specified by the user, the motor drives the synchronous pulley, the slider is driven by the ball screw, and the end slider is driven by the booster mechanism. Movement in the vertical direction drives the mold to work. figure 2 It is the mechanism and force analysis diagram of the forging press, where point A is fixed, point C is the slider 1, and point D is connected with the screw rod. When the screw rod moves up and down, it drives the rod c to move. Since A is fixed, joint B drives the rod b movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com