Method for manufacturing polyvinyl alcohol slow/controlled release film

A film manufacturing method and polyvinyl alcohol technology, applied in the field of film manufacturing, can solve the problems of limiting the application range of microporous slow-release films, failing to meet the needs of adjustable slow-release speed, unfavorable packaging of fine powder, liquid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

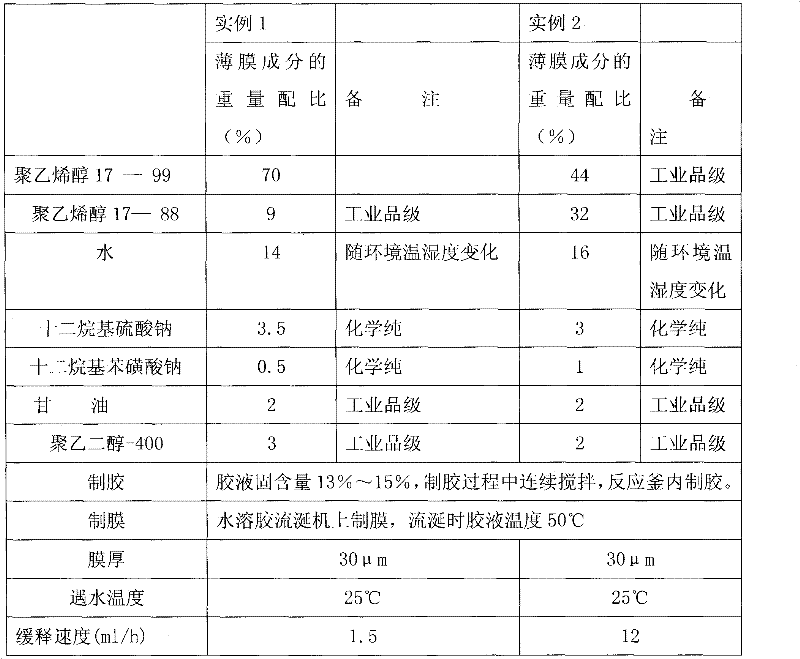

[0015] The present invention is described in detail with examples below.

[0016] The polyvinyl alcohol sustained-release / controlled-release film-making process of the present invention is to add film-forming components, plasticizers and water into the reactor in proportion, stir and heat to a certain temperature (80°C to 95°C) to form a gel. After gluing, drop to a certain temperature (60°C-70°C) and add various additives such as surfactants, stir evenly to make a rubber compound with a solid content of 13%-18%. Use hydrosol salivating machine to cast film.

[0017] The specific embodiment list of the present invention is as follows:

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com