PVA (polyvinyl alcohol)/starch slow release thin film with herbicide controlled-release property and preparation method thereof

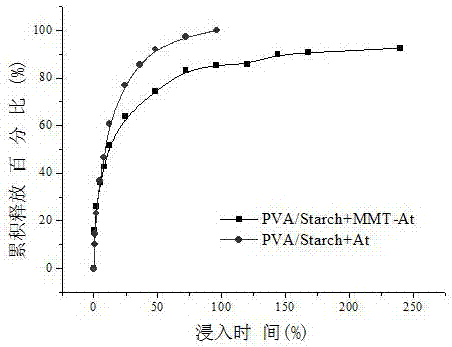

A herbicide and slow-release technology, which is applied in the field of PVA/starch slow-release film and its preparation, can solve the problems of slow release of pesticides and poor rain resistance, and achieve the effect of prolonging the drug effect period and reducing the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

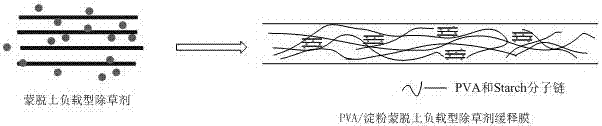

[0043] Dissolve 0.2 g of atrazine in methanol, add 1.8 g of montmorillonite, stir for 48 hours, centrifuge to remove the supernatant, and vacuum dry the product at 50°C for 16 hours to obtain atrazine-loaded montmorillonite-loaded Herbicides, spare.

[0044] In a 250ml flask, add 5g of cornstarch and 45g of deionized water, stir at 80°C at a speed of 650rpm for 1h to form a paste. In a second flask was added 5 g of polyvinyl alcohol dissolved in 45 g of deionized water (80 °C water bath).

[0045] Pour the mixed solution in the second flask into the first flask, then add 2g of glycerol and 0.3g of glyceryl monostearate to the mixed solution, mix and stir at a speed of 300rpm for 1h, and then add the above-mentioned The montmorillonite-loaded herbicide loaded with atrazine was stirred for 5 hours until a uniform viscous substance was obtained.

[0046] Spread the prepared viscous evenly on a dry and clean mold to form a liquid layer with uniform thickness and smooth surface, ...

Embodiment 2

[0048] Dissolve 0.05g of atrazine in methanol, then add 0.5g of montmorillonite, stir for 24 hours, centrifuge to remove the supernatant, and vacuum dry the product at 40°C for 24 hours to obtain atrazine-loaded montmorillonite-loaded Herbicides, spare.

[0049] In a 250ml flask, add 2g of cornstarch and 18g of deionized water, stir at 70°C at a speed of 500rpm for 0.5h to form a paste. In a second flask, 8 g of polyvinyl alcohol was dissolved in 72 g of deionized water (70 °C water bath).

[0050]Pour the mixed solution in the second flask into the first flask, then add 1g of glycerol and 0.1g of glyceryl monostearate to the mixed solution, mix and stir at 200°C for 1h, then add the above-mentioned The montmorillonite-loaded herbicide loaded with 2,4-dichlorophenoxyacetic acid was stirred for 2 hours until a uniform viscous substance was obtained.

[0051] Spread the prepared viscous evenly on a dry and clean mold to form a liquid layer with uniform thickness and smooth sur...

Embodiment 3

[0053] Dissolve 0.4g of atrazine in ethanol, then add 3g of montmorillonite, stir for 72 hours, centrifuge to remove the supernatant, and vacuum dry the product at 60°C for 8 hours to obtain atrazine-loaded montmorillonite-loaded herbicide agent, spare.

[0054] In a 250ml flask, add 8g of cornstarch and 72g of deionized water, and stir at 90°C at a speed of 800rpm for 2h to form a paste. In a second flask was added 2 g of polyvinyl alcohol dissolved in 18 g of deionized water (90 °C water bath).

[0055] Pour the mixed solution in the second flask into the second flask, then add 3 parts of glycerol and 0.5 g of glyceryl monostearate to the mixed solution, mix and stir evenly, and mix and stir at a speed of 500 rpm for 0.5 h, then add the atrazine-loaded montmorillonite-loaded herbicide prepared above, and continue stirring for 4 h until a uniform viscous substance is obtained.

[0056] Evenly spread the prepared viscous material on a dry and clean mold to form a liquid laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com