Polyvinyl alcohol starch sustained-release film with controlled plant pesticide releasing performance and preparation method thereof

A technology for polyvinyl alcohol and plant pesticides, applied in the field of agricultural materials, can solve the problem of less sustained-release film, and achieve the effects of reducing the release rate, enriching the source of raw materials, and prolonging the efficacy period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

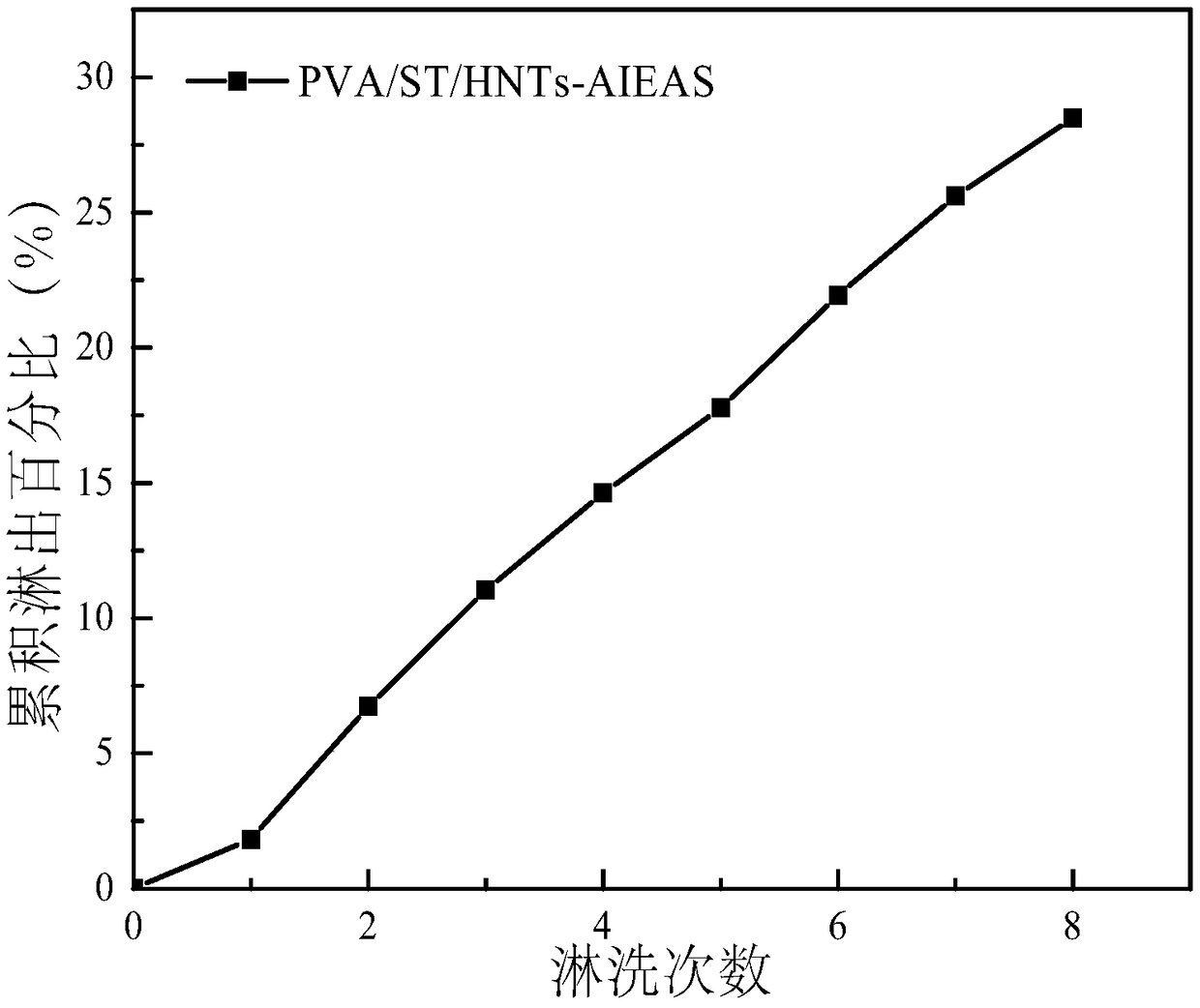

Embodiment 1

[0045] (1) Dried the stems and leaves of Eupatorium adenophorum, powdered them, weighed 15g of dry powder and wrapped them with filter paper, then added 100ml of absolute ethanol to heat and reflux for extraction for 12 hours. Rotate the extract under reduced pressure, dissolve the water phase, and centrifuge to obtain the supernatant, and dry it to constant weight to obtain the plant pesticide AIEAS.

[0046] (2) Weigh 0.1g AIEAS and dissolve it in 100ml methanol, then add 1g halloysite nanotubes, stir magnetically for 1h, vacuumize, deflate and stir, centrifuge to remove the supernatant, and blow dry at 60°C for 36h to obtain Halloysite nanotube-supported plant pesticides (HNTs-AIEAS).

[0047] (3) Mix 2 g of cornstarch with 18 g of deionized water, stir in a constant temperature water bath at 90°C at a speed of 500 rpm for 30 min to form a translucent paste.

[0048] (4) Weigh 8g of polyvinyl alcohol and dissolve it in 72g of deionized water in a 90°C water bath, then pour...

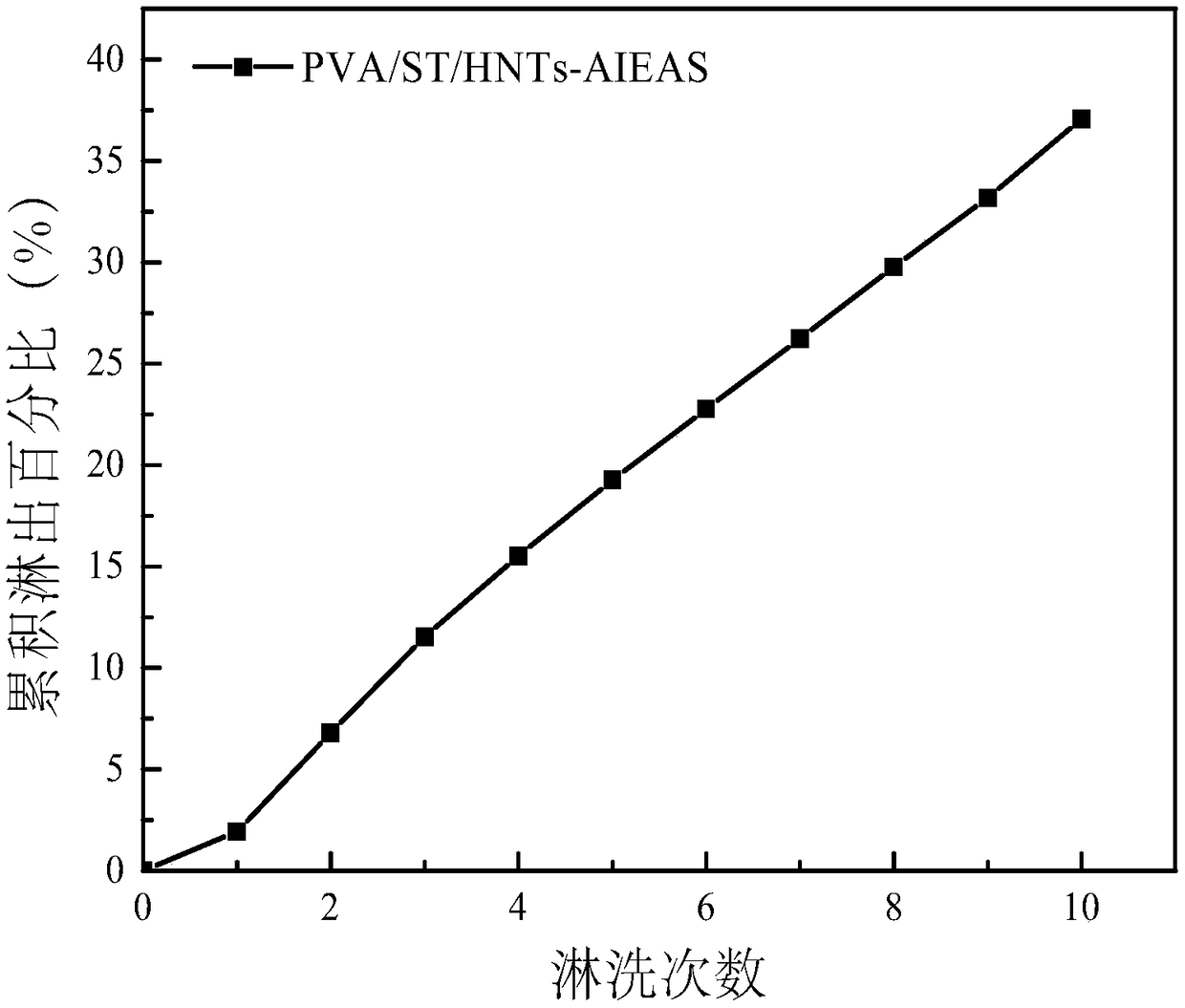

Embodiment 2

[0053](1) Dried the stems and leaves of Eupatorium adenophorum, powdered them, weighed 15g of dry powder and wrapped them with filter paper, then added 100ml of absolute ethanol to heat and reflux for extraction for 12 hours. Rotate the extract under reduced pressure, dissolve the water phase, and centrifuge to obtain the supernatant, and dry it to constant weight to obtain the plant pesticide AIEAS.

[0054] (2) Weigh 0.3g AIEAS and dissolve in 100ml methanol, then add 2g halloysite nanotubes, stir magnetically for 1.5h, vacuumize, deflate and stir, centrifuge to remove the supernatant, and dry at 60°C for 36h. Halloysite nanotube-loaded plant pesticides (HNTs-AIEAS).

[0055] (3) Mix 2 g of cornstarch with 18 g of deionized water, stir in a constant temperature water bath at 90°C at a speed of 500 rpm for 30 min to form a translucent paste.

[0056] (4) Weigh 8g of polyvinyl alcohol and dissolve it in 72g of deionized water in a 90°C water bath, then pour it into the transl...

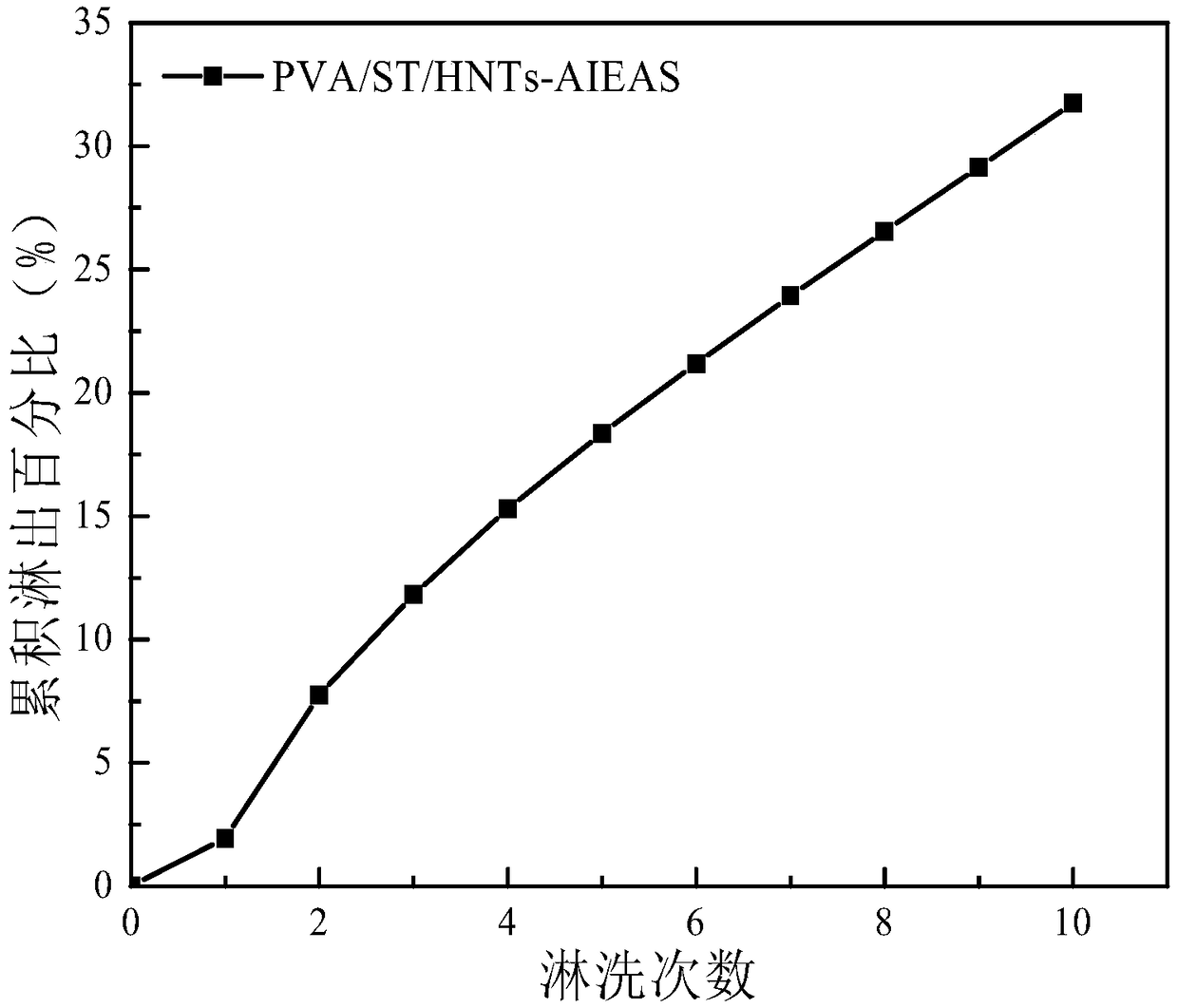

Embodiment 3

[0061] (1) Dried the stems and leaves of Eupatorium adenophorum, powdered them, weighed 15g of dry powder and wrapped them with filter paper, then added 100ml of absolute ethanol to heat and reflux for extraction for 12 hours. Rotate the extract under reduced pressure, dissolve the water phase, and centrifuge to obtain the supernatant, and dry it to constant weight to obtain the plant pesticide AIEAS.

[0062] (2) Weigh 0.5g AIEAS and dissolve it in 100ml methanol, then add 3g halloysite nanotubes, stir magnetically for 1h, vacuumize, deflate and stir, centrifuge to remove the supernatant, and dry at 80°C for 24h to obtain Halloysite nanotube-supported plant pesticides (HNTs-AIEAS).

[0063] (3) Mix 2 g of cornstarch with 18 g of deionized water, stir in a constant temperature water bath at 90°C at a speed of 500 rpm for 30 min to form a translucent paste.

[0064] (4) Weigh 8g of polyvinyl alcohol and dissolve it in 72g of deionized water in a 90°C water bath, then pour it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com