Fluorocarbon metal light composite board and manufacturing method thereof

A composite board, fluorocarbon technology, applied in metal layered products, chemical instruments and methods, covering/lining, etc., can solve the problems of poor thermal insulation performance, poor thermal insulation effect, and difficult separation of fluorocarbon metal light composite boards , to achieve the effect of good heat insulation, material saving and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

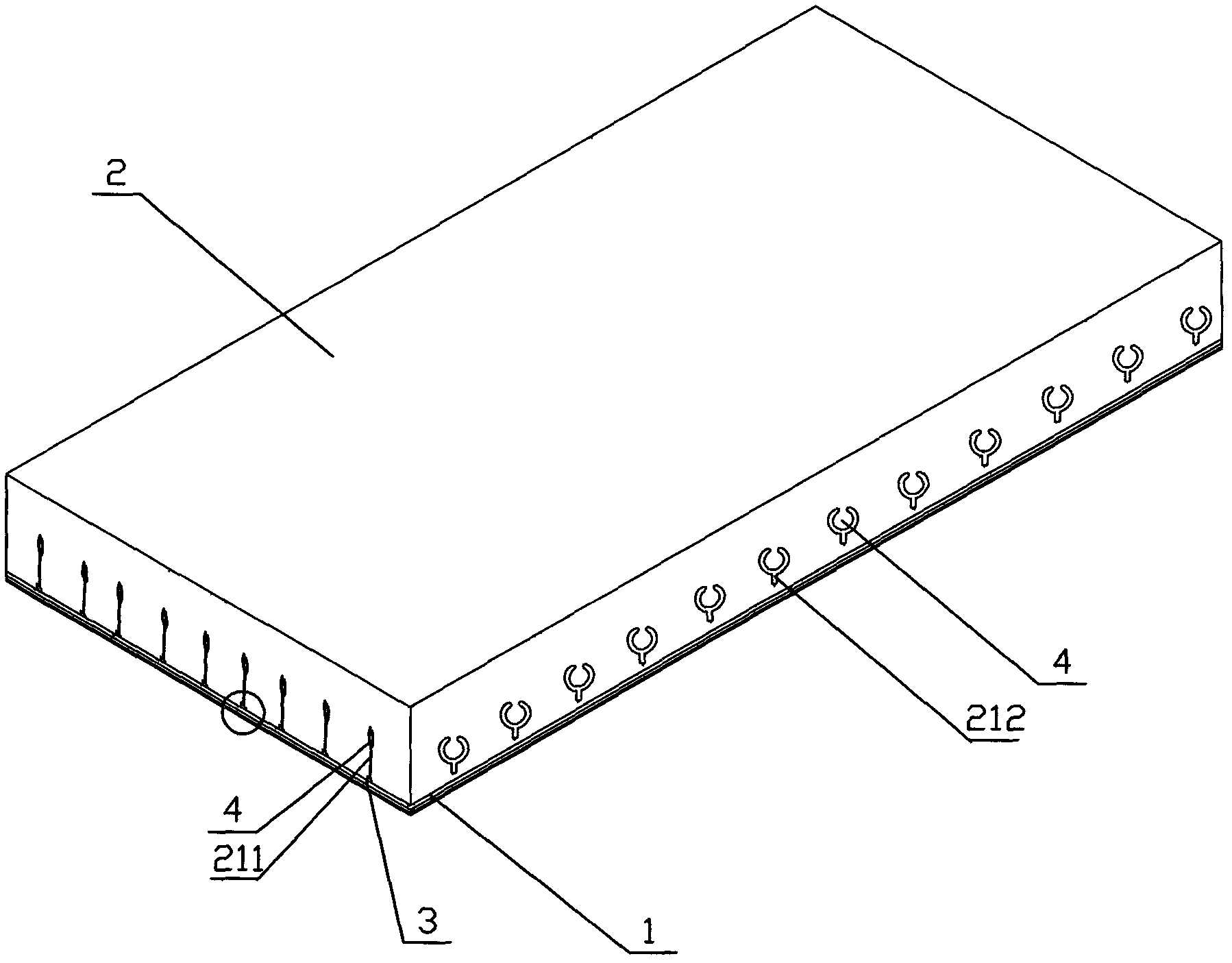

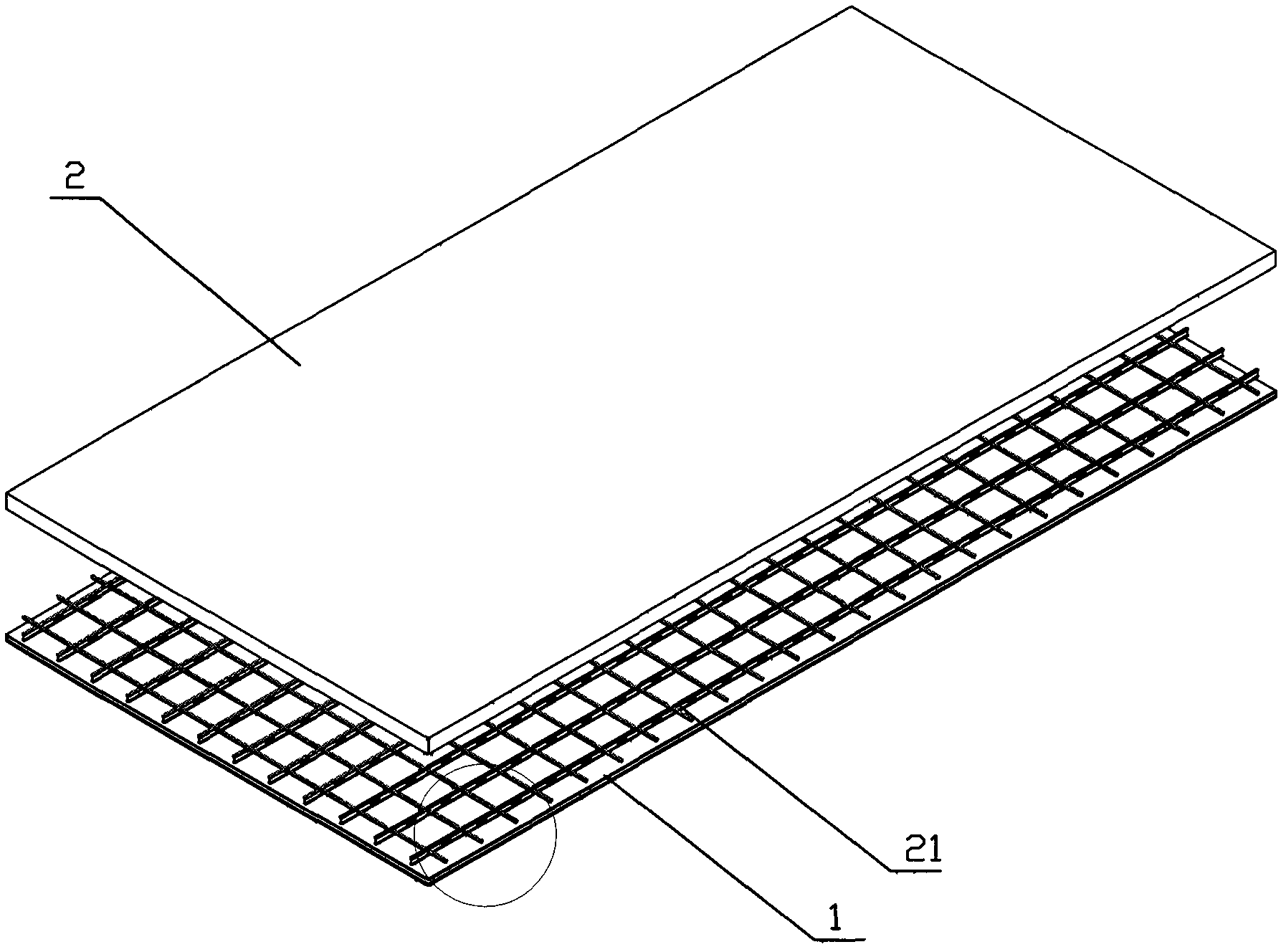

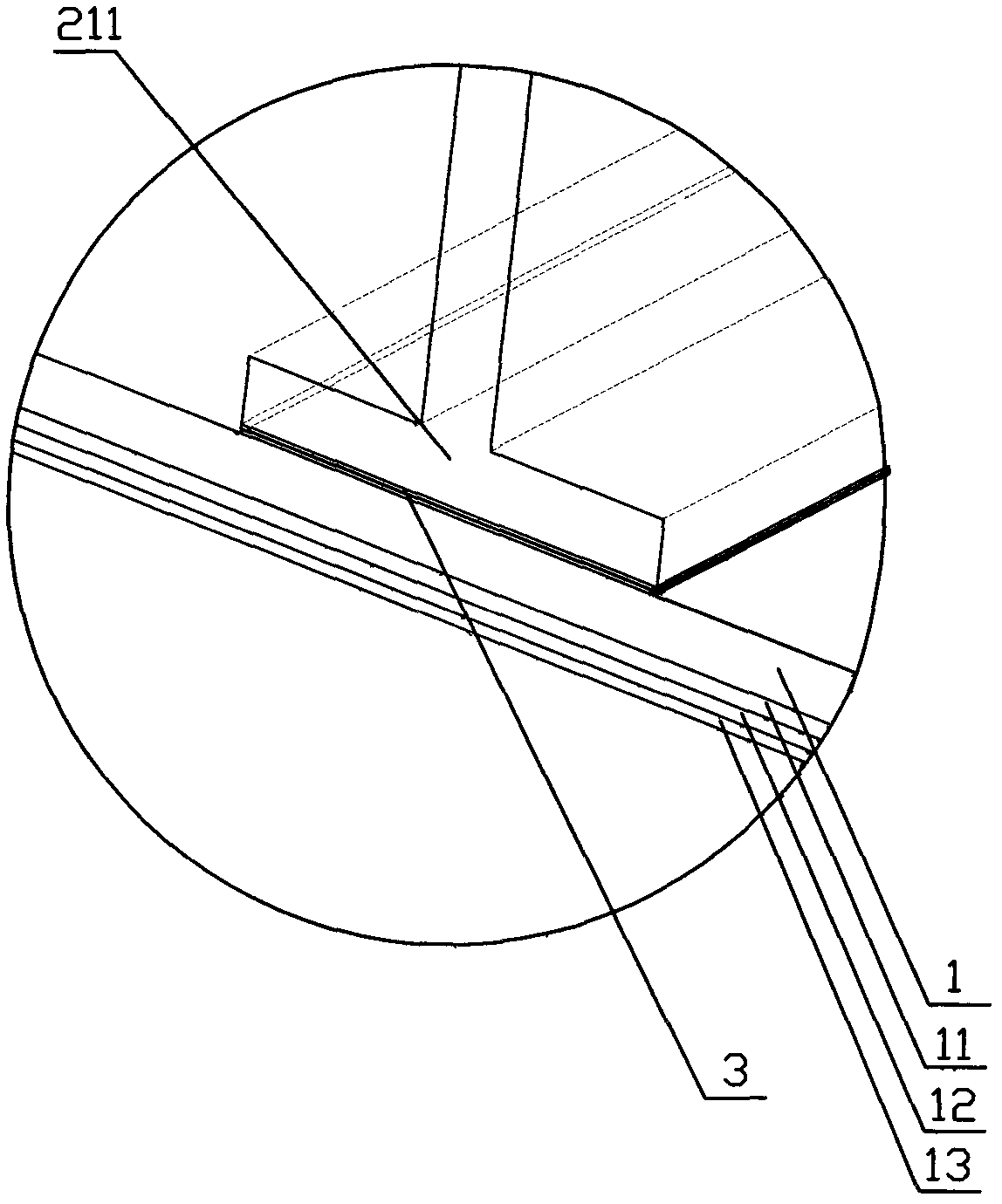

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a light-duty fluorocarbon metal composite board includes two layers, the upper layer is a foam insulation layer 2, the lower layer is an aluminum veneer 1, and a fluorocarbon layer is adhered to the outer surface of the aluminum veneer 1. The foam insulation A grid 21 is provided in the heat layer 2, and the grid 21 is formed by interlacing longitudinal and horizontal reinforcement ribs 211 and horizontal reinforcement ribs 212, and bolts are provided on the vertical reinforcement ribs 211 and the horizontal reinforcement ribs 212 The fixing groove 4 is provided with several guide holes 2111 on the reinforcing rib 211 placed longitudinally, and the adhesive layer 3 is provided between the grid 21 and the aluminum veneer 1 . The outer surface of the aluminum veneer 1 is sequentially adhered with a sprayed base color layer 11 , a fluorocarbon texture layer 12 , and an anti-ultraviolet UV layer 13 . Both th...

Embodiment 2

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a light-duty fluorocarbon metal composite board includes two layers, the upper layer is a foam heat insulation layer 2, the lower layer is an aluminum veneer 1, and a fluorocarbon layer is adhered to the outer surface of the aluminum veneer 1. The foam insulation A grid 21 is provided in the thermal layer 2, and the grid 21 is formed by interlacing longitudinal and horizontal reinforcement ribs 211 and horizontal reinforcement ribs 212, and bolts are provided on the vertical reinforcement ribs 211 and the horizontal reinforcement ribs 212 The fixing groove 4 is provided with several guide holes 2111 on the reinforcing rib 211 placed longitudinally, and the adhesive layer 3 is provided between the grid 21 and the aluminum veneer 1 . The outer surface of the aluminum veneer 1 is sequentially adhered with a sprayed base color layer 11 , a fluorocarbon texture layer 12 , and an anti-ultraviolet UV layer 13 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com