Aluminum clad wood thermal insulation window having heat transfer coefficient less than 0.8

A heat transfer coefficient, aluminum-clad wood technology, applied to windows/doors, soundproof doors/windows, building components, etc., can solve the problems of heat energy waste, poor heat preservation, etc., and achieve the effect of saving heat energy and improving heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

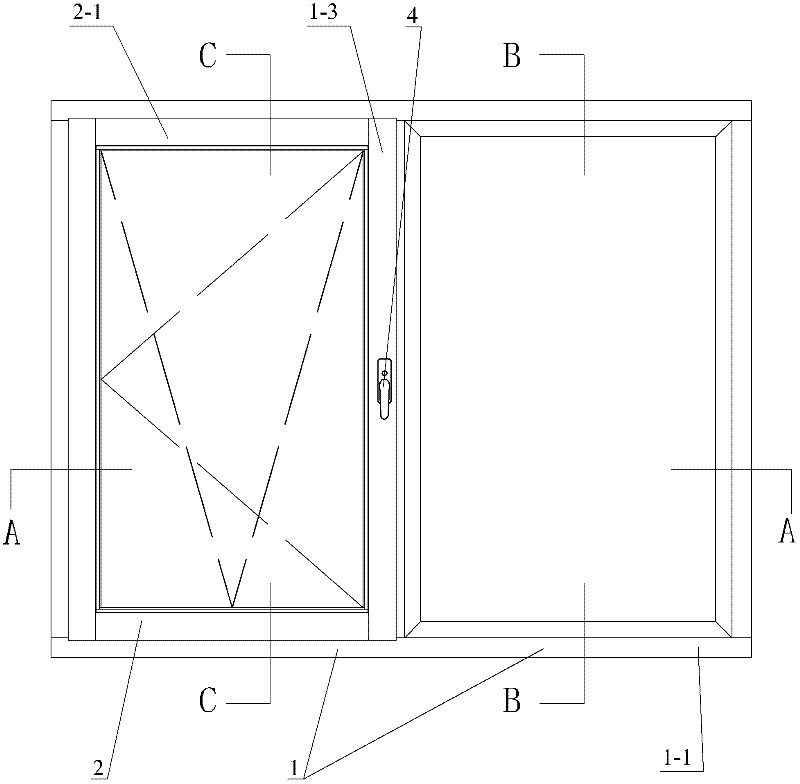

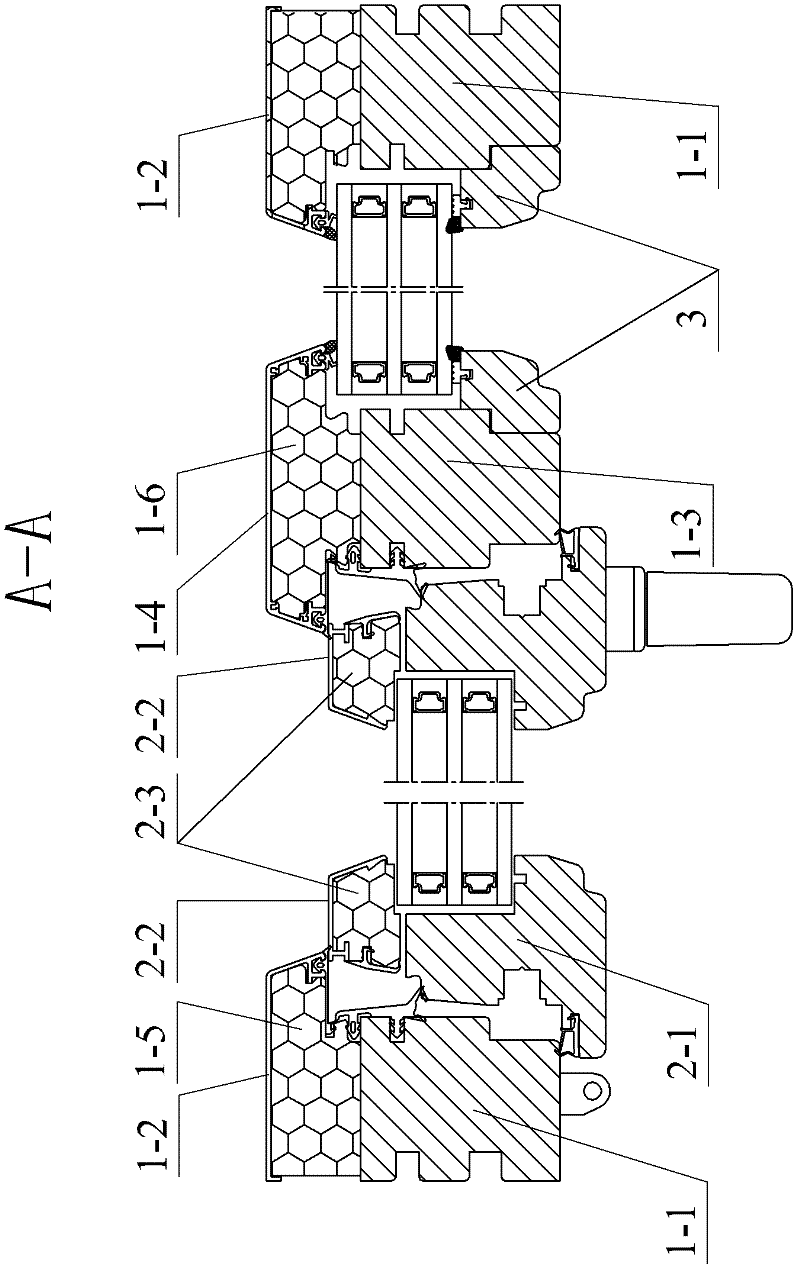

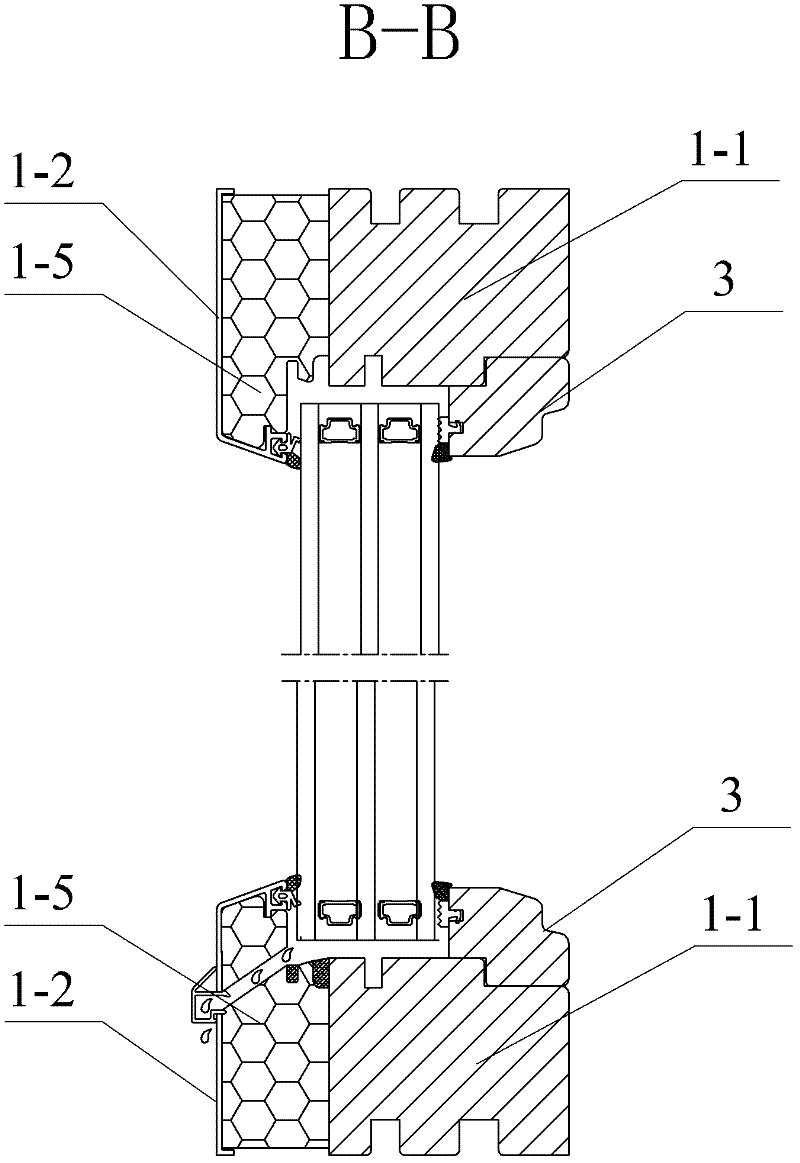

[0008] Specific implementation mode one: as Figure 1 ~ Figure 4 As shown, the aluminum-clad wood thermal insulation window with a heat transfer coefficient of 0.8 or less described in this embodiment includes a window frame 1 and a window sash 2 installed in the window frame 1 through a hinge, and the window frame 1 includes a wooden frame 1-1, Aluminum frame 1-2, at least one stile and multiple wooden buckles 3, said at least one stile is vertically or horizontally fixed in the window frame 1, said at least one stile includes wooden stile 1-3 and aluminum The middle stile 1-4, the window sash 2 includes a wooden frame 2-1 and an aluminum frame 2-2, the wooden frame 1-1 with fixed glass and the wooden middle stile 1-3 are fixed with a wooden buckle 3 , the window frame 1 also includes a heat insulating profile frame 1-5 and a heat insulating profile frame 1-6, the window sash 2 also includes a heat insulating profile frame 2-3, and the aluminum frame 1-2 passes through the he...

specific Embodiment approach 2

[0009] Embodiment 2: The heat-insulating profile frame 1-5 and the heat-insulating profile stile 1-6 described in this embodiment are both extruded boards. This design has good thermal insulation performance. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The heat-insulating profile frames 1-5 and the heat-insulating profile mid-stiles 1-6 in this embodiment are all benzene boards. This design has good thermal insulation performance. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com