Electromagnetic acoustic sensor with consistent circumferential direction and single S0 mode Lamb wave

A sensor, electromagnetic sound technology, applied in the direction of ultrasonic/sonic/infrasonic generation, etc., can solve the problems of large error, dependence, and difficulty in excitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

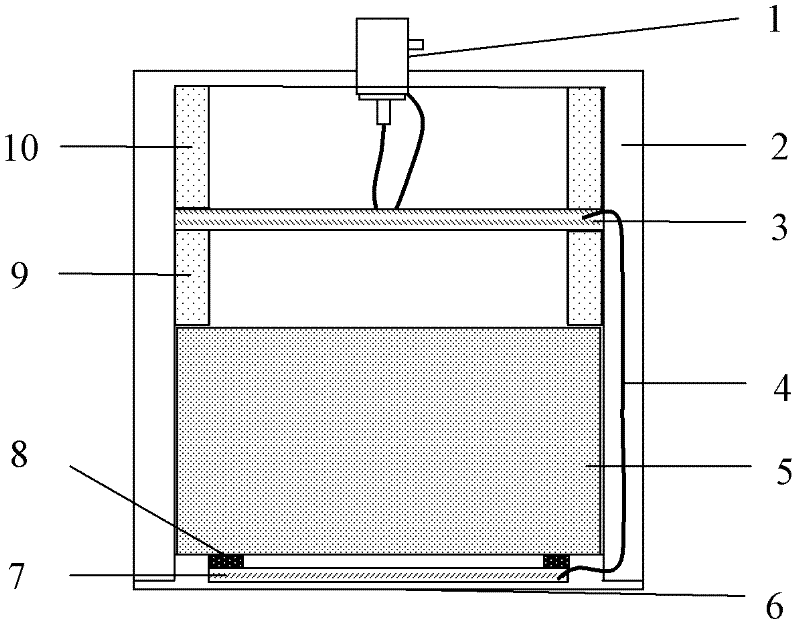

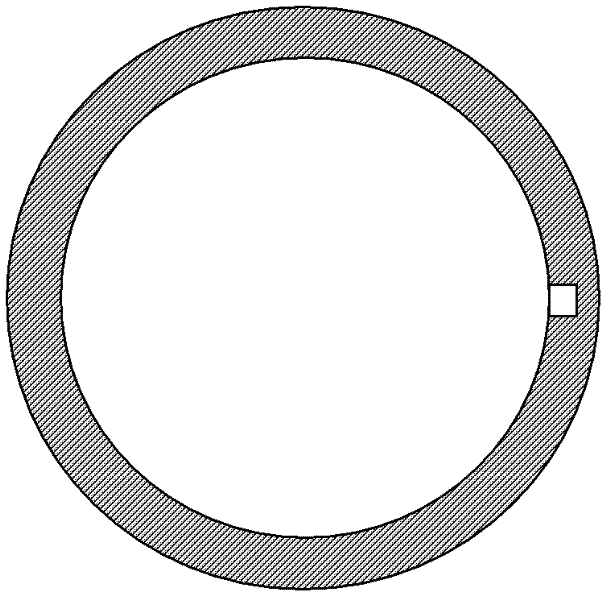

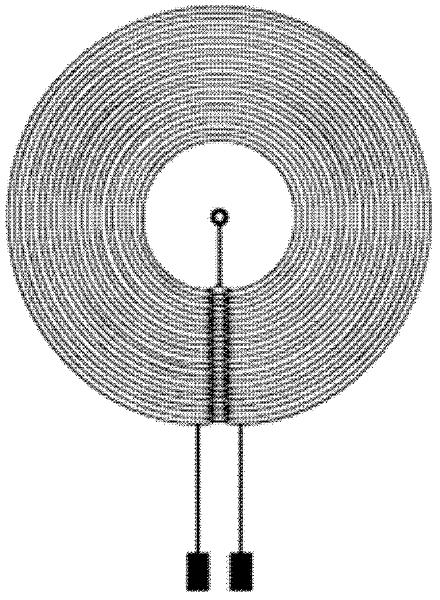

[0028] Such as figure 1 As shown, the sensor of the present invention consists of a BNC joint (1) (bayonet nut connector), a protective shell (2), an impedance matching circuit (3), a lead (4), a magnet (5), and an end protective shell (6) , ring coil (7), spacer (8) and support sleeve (9, 10), such as figure 1 shown in . The lower end of the protective shell (2) is open, and the end protective shell (6) is connected to it at the opening of the protective shell (2), and the ring coil (7) is placed in the end protective shell (6), and a gasket ( 8), the magnet (5) is placed directly above the ring coil (7), a support sleeve (9) is placed on the magnet (5), and an impedance matching circuit (3) is arranged on the support sleeve (9), and the other A support sleeve (10) is placed between the upper top of the protective shell (2) and the impedance matc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com