Assembling device and method of crystal arrays of PET (Polyethylene Terephthalate) detector

A technology for crystal arrays and assembling devices, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of errors in manual alignment operations, difficulty in ensuring uniform alignment of optical glue thickness, and affecting detector performance, etc., and achieves a simple structure. , easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

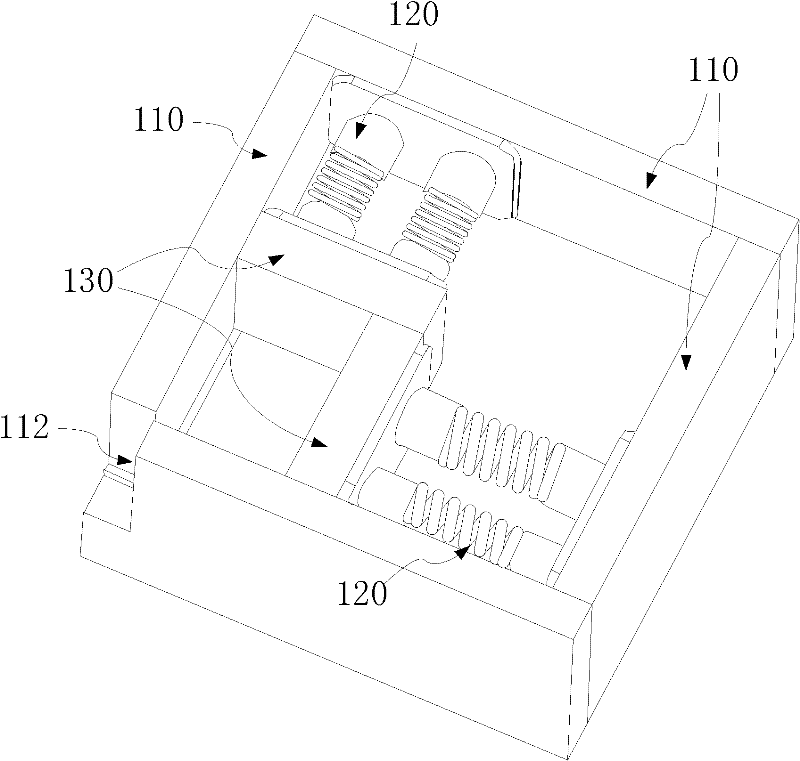

[0038] figure 1 A schematic structural diagram of an assembly device for a PET detector crystal array according to an embodiment of the present invention is shown.

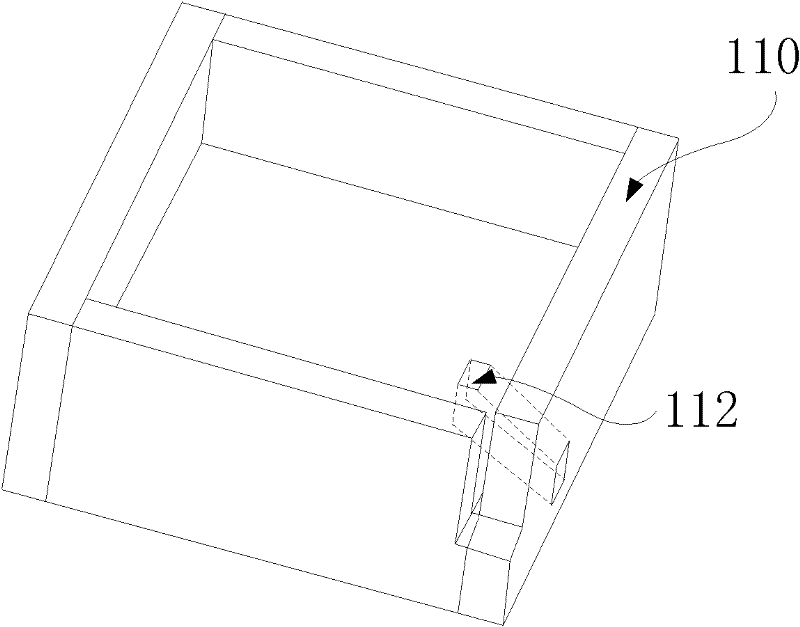

[0039] like figure 1 As shown, the assembly device of the PET detector crystal array provided by the present invention includes a square frame 110, two pushing components 120 and two spring clamps 130 connected to the two pushing components respectively, and the other parts of the two spring clamps 130 are One end is respectively fixed on the two opposite ends of the two adjacent sides of the square frame 110, and the space formed by the other two adjacent sides of the square frame 110 and the two pushing components 120 is the space of the basic crystal array unit to be assembled. Elastic extrusion shaping space.

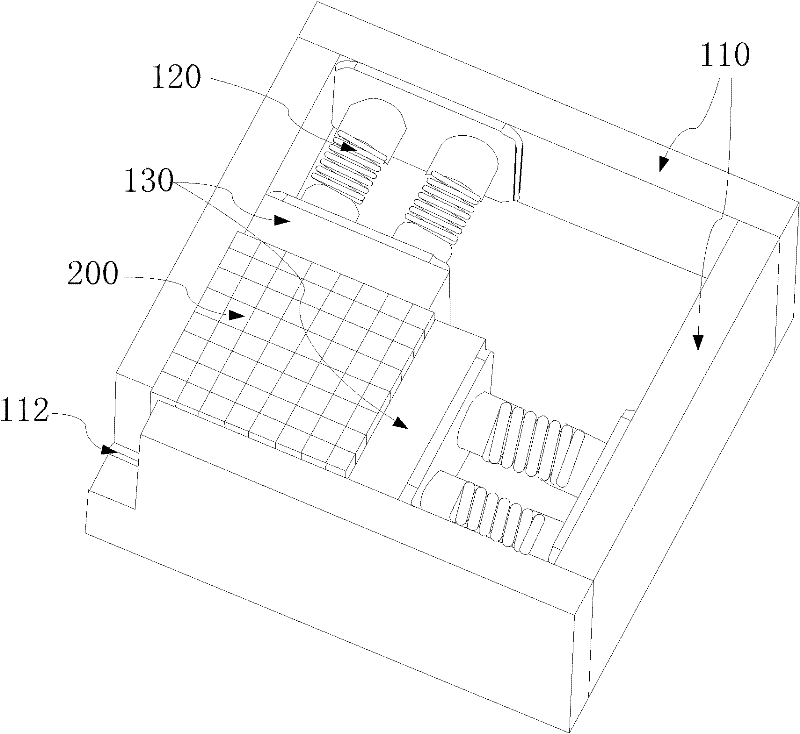

[0040] figure 2 It is a structural schematic diagram of an as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com