Cell characteristic vector based lithium ion cell configuration method

A technology of lithium-ion batteries and eigenvectors, which is applied in the fields of non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary battery repair/maintenance, etc. It can solve the problems of poor overall performance of battery packs and inability to fully reflect battery differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

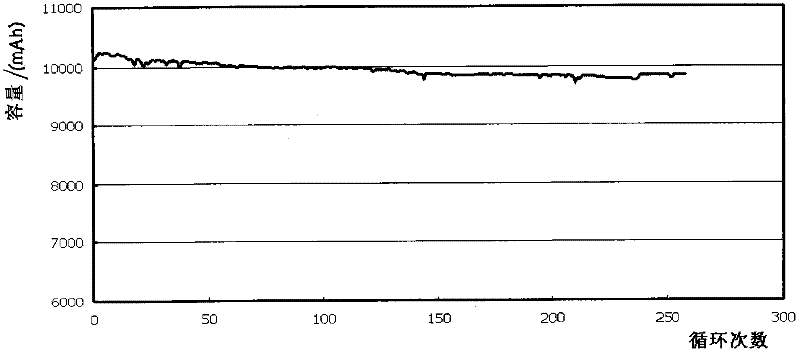

[0029] The present embodiment selects the IMP1865130 battery (nominal capacity 10Ah) that our company produces based on the lithium-ion battery grouping method of battery feature vector, and production batch is 20110706; It comprises the following steps:

[0030] 1. Place the lithium-ion battery to be assembled on the lithium-ion battery program-controlled test equipment for charge and discharge detection. The detection process is set as:

[0031] 1.1. Constant current discharge: constant current 2A, cut-off voltage 2.7V,

[0032] 1.2, standing still: standing time 30 minutes,

[0033] 1.3. Constant current charging: constant current 20A, cut-off voltage 4.2V,

[0034] 1.4. Constant voltage charging: constant voltage 4.2V, cut-off current 200mA,

[0035] 1.5, standing still: standing time 30 minutes,

[0036] 1.6. Constant current discharge: constant current 20A, cut-off voltage 2.7V,

[0037] 1.7, standing still: standing time 240 minutes;

[0038] 2. Collect and record ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com