Silicic miniature microphone

A microphone and silicon micro technology, applied in the direction of electrostatic transducer microphone, etc., can solve the problems of damage to silicon acoustic chip and poor reliability, and achieve the effect of improving yield, improving reliability and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

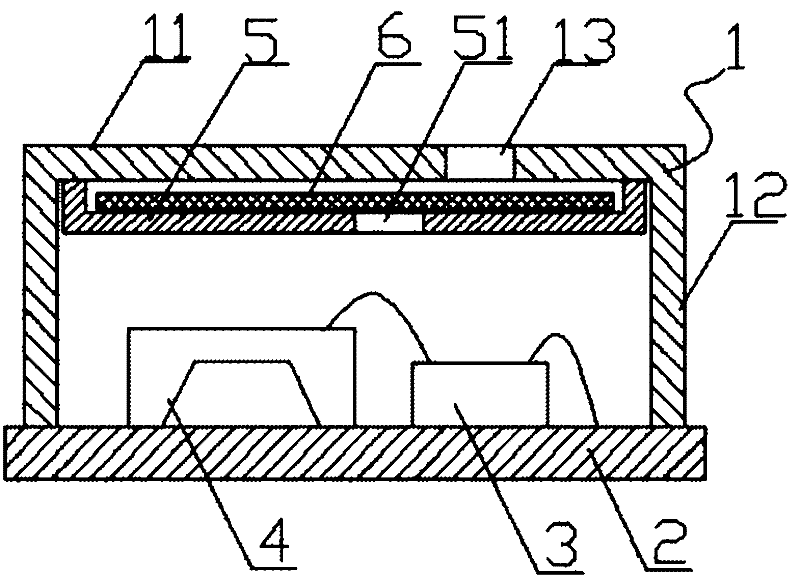

[0020] figure 1 It is a sectional view of a silicon micro-microphone according to the embodiment of the present invention, as figure 1 As shown, the silicon micro-microphone includes an upper plate 11 combined from top to bottom, a side wall formed by a hollow cavity 12, and an external packaging structure formed by a circuit board lower plate 2, which is arranged on the upper plate 11 There is a first sound inlet 11, and the inside of the packaging structure is provided with a silicon acoustic chip 4 and an electrical signal processing chip 3 installed on the lower board 2 of the circuit board; an isolation device 5 is also provided on the upper board 11 inside the packaging structure to isolate A buffer cavity is formed between the device 5 and the upper plate 11. A second sound inlet 51 connecting the first sound inlet 11 and the silicon acoustic chip 4 is provided on the isolation device 5. The first sound inlet 11 and the second A blocking sheet 6 is also arranged betw...

Embodiment 2

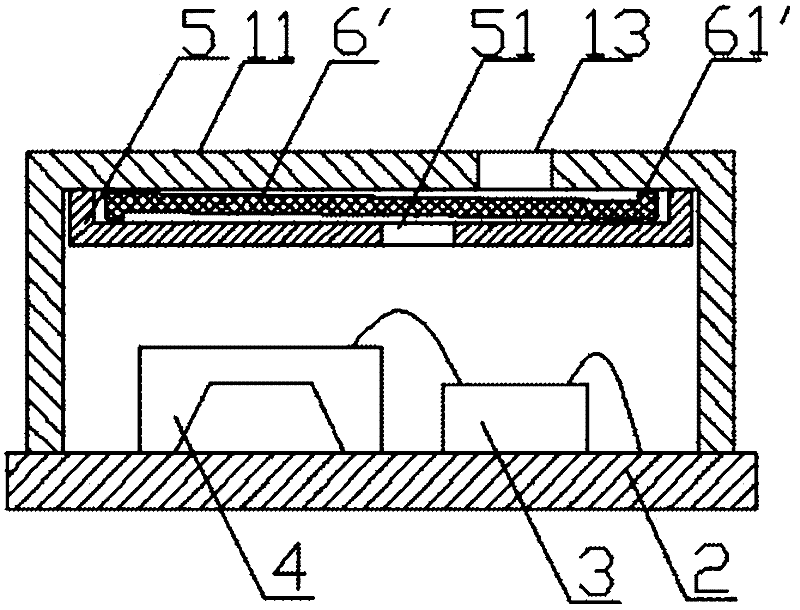

[0025] figure 2 It is a sectional view of the second silicon micro-microphone of the embodiment of the present invention, as figure 2 As shown, the main difference between this implementation process and Embodiment 1 is that the two ends of the blocking piece 6' in this implementation process are provided with opposite direction supports 61', so that the structure of the blocking piece 6' presents an S shape.

[0026] This design, in practical application, the structural characteristics of the blocking sheet 6' makes it have a greater sound transmission effect, which can meet the needs of more production designs for sound transmission.

Embodiment 3

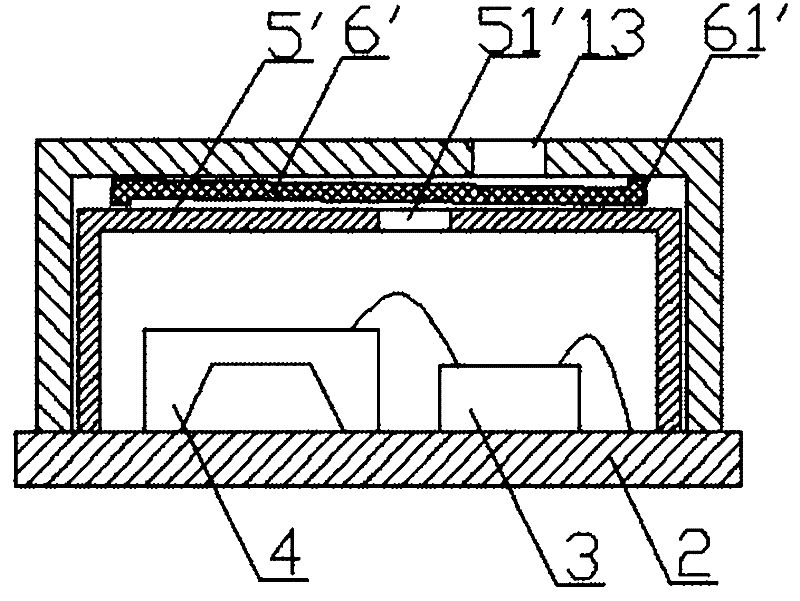

[0028] image 3 It is a sectional view of the silicon micro-microphone of the embodiment of the present invention, as image 3 As shown, the main difference between this implementation process and the above-mentioned implementation process is that the setting of the isolation device 5' is different, and the isolation device 5' in this implementation process is arranged on the lower board 2 of the circuit board.

[0029] The design of this implementation process can also achieve the above-mentioned technical effect, and the design of the isolation device in this implementation process is more convenient when assembling the silicon micro-microphone.

[0030] In the implementation of the present invention, the blocking sheet can also be in other shapes such as L shape, and the design of the specific shape can be selected according to the requirements of the sound penetration effect; the upper plate and the cavity can also be independent structures, that is, three-layer plate stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com