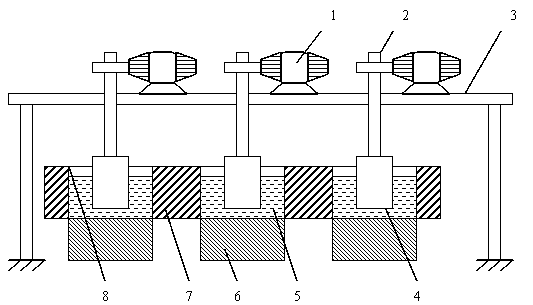

Built-in type electromagnetic stirring device and application method thereof

An electromagnetic stirring and electromagnetic stirrer technology, applied in the field of built-in electromagnetic stirring devices, can solve the problems of insufficient space for installation, difficulty in adapting to multi-stream casting conditions, low energy utilization rate, etc., and achieves high use efficiency, compact structure, small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

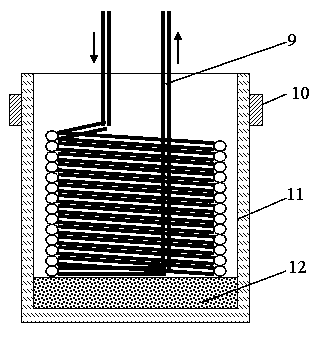

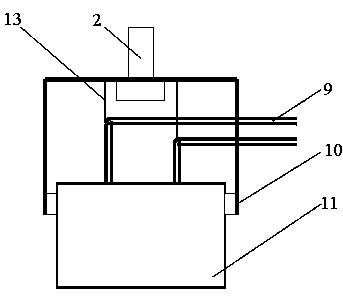

Embodiment 1

[0027] To produce A356 alloy ingots with a diameter of 200mm by semi-continuous casting, the specific steps are: use water-cooled copper coils to make a horizontal rotating magnetic field electromagnetic stirrer to form a horizontal rotating magnetic field with a frequency of 0.3 Hz, and the copper tubes are separated by insulating varnish and insulating cloth. The inner diameter of the copper tube is 5mm, the outer diameter is 8mm, and it is wound into a coil with an outer diameter of 100mm and a height of 100mm. The electromagnetic stirrer is protected by a heat-resistant alumina ceramic protective sleeve, and the alumina ceramic protective sleeve is made of nano-Al 2 o 3Toughened, with an inner diameter of 120mm, an outer diameter of 140mm, and a height of 200mm. During use, alumina ceramic particles with a particle size of 100μm are spread on the bottom of the ceramic protection tube, and the thickness is 5mm. The electromagnetic stirrer and heat-resistant ceramic protectiv...

Embodiment 2

[0032] To produce 6061 alloy ingots with a diameter of 200mm by semi-continuous casting, water-cooled copper coils are used to make a horizontal rotating magnetic field electromagnetic stirrer to form a horizontal rotating magnetic field with a frequency of 0.8 Hz. The copper tubes are separated by insulating paint and insulating cloth. The inner diameter of the copper tubes 5mm, outer diameter 8mm, wound into a coil with an outer diameter of 100mm and a height of 100mm, the electromagnetic stirrer is protected by a heat-resistant alumina ceramic protective sleeve, and the alumina ceramic protective sleeve is made of nano-Al 2 o 3 Toughened, with an inner diameter of 120mm, an outer diameter of 140mm, and a height of 200mm. During use, alumina ceramic particles with a particle size of 200μm are spread on the bottom of the ceramic protection tube, and the thickness is 6mm. The electromagnetic stirrer and heat-resistant ceramic protective sleeve are fixed. On the guide rod above...

Embodiment 3

[0035] To use semi-continuous casting to produce A356 alloy ingots with a diameter of 250mm, water-cooled copper coils are used to make a horizontal rotating magnetic field electromagnetic stirrer to form a horizontal rotating magnetic field with a frequency of 1.5Hz. The copper tubes are separated by insulating paint and insulating cloth, and the inner diameter of the copper tubes 10mm, outer diameter 14mm, wound into a coil with an outer diameter of 150mm and a height of 130mm, the electromagnetic stirrer is protected by a heat-resistant alumina ceramic protective sleeve, and the alumina ceramic protective sleeve is made of nano-Al 2 o 3 Toughened, with an inner diameter of 180mm, an outer diameter of 210mm, and a height of 250mm. During use, magnesia particles with a particle size of 400μm are spread on the bottom of the ceramic protection tube with a thickness of 10mm. The electromagnetic stirrer and heat-resistant ceramic protective sleeve are fixed on the On the guide ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com