Magnetron sputtering source and magnetron sputtering device

A magnetron sputtering and magnet technology, which is applied in the field of magnetron sputtering, can solve the problems of poor sputtering uniformity and low utilization rate of target materials, and achieves the advantages of increasing the number of collisions, improving the utilization rate of sputtering and the uniformity of sputtering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the embodiments of the present invention will be further described in detail below through the accompanying drawings and embodiments.

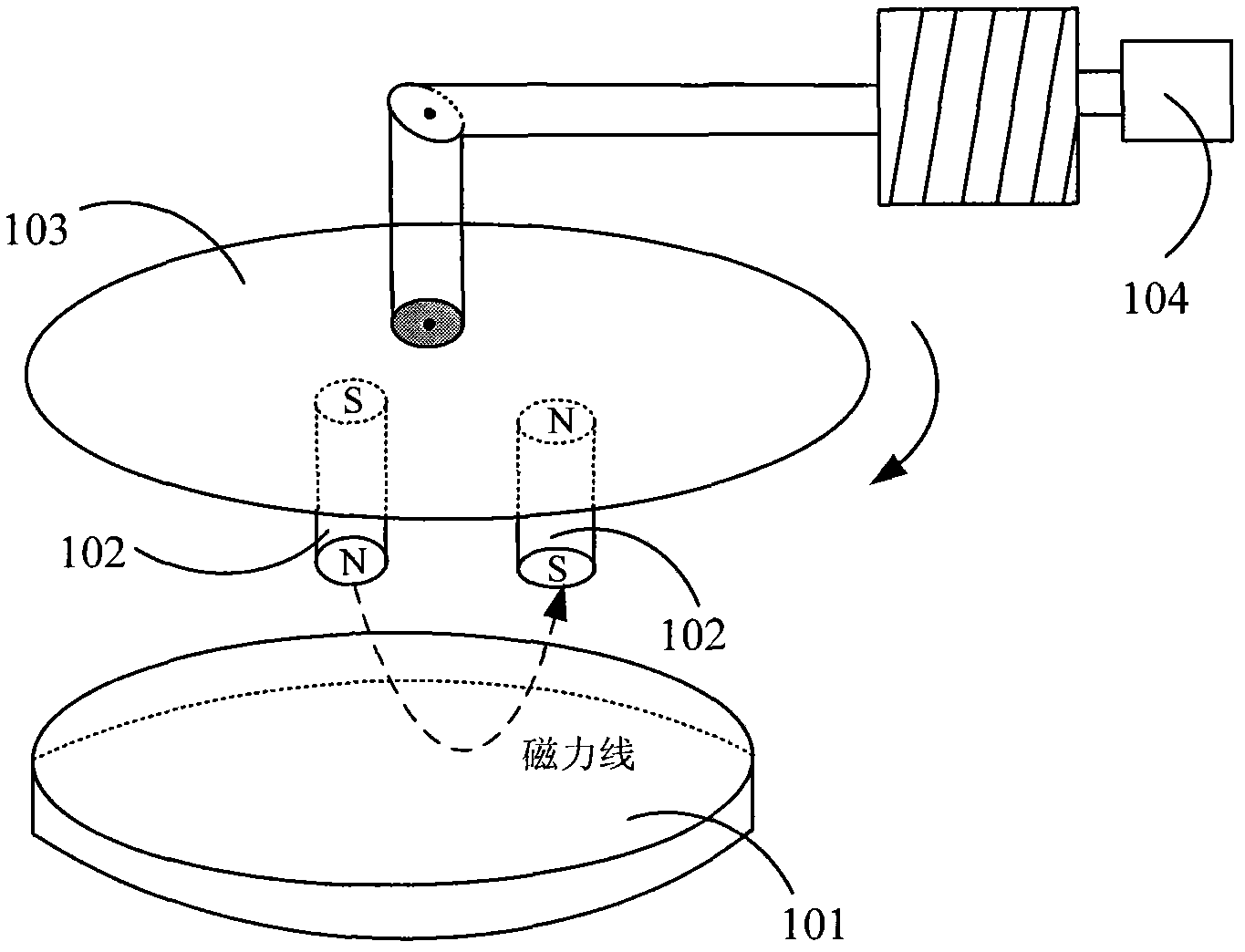

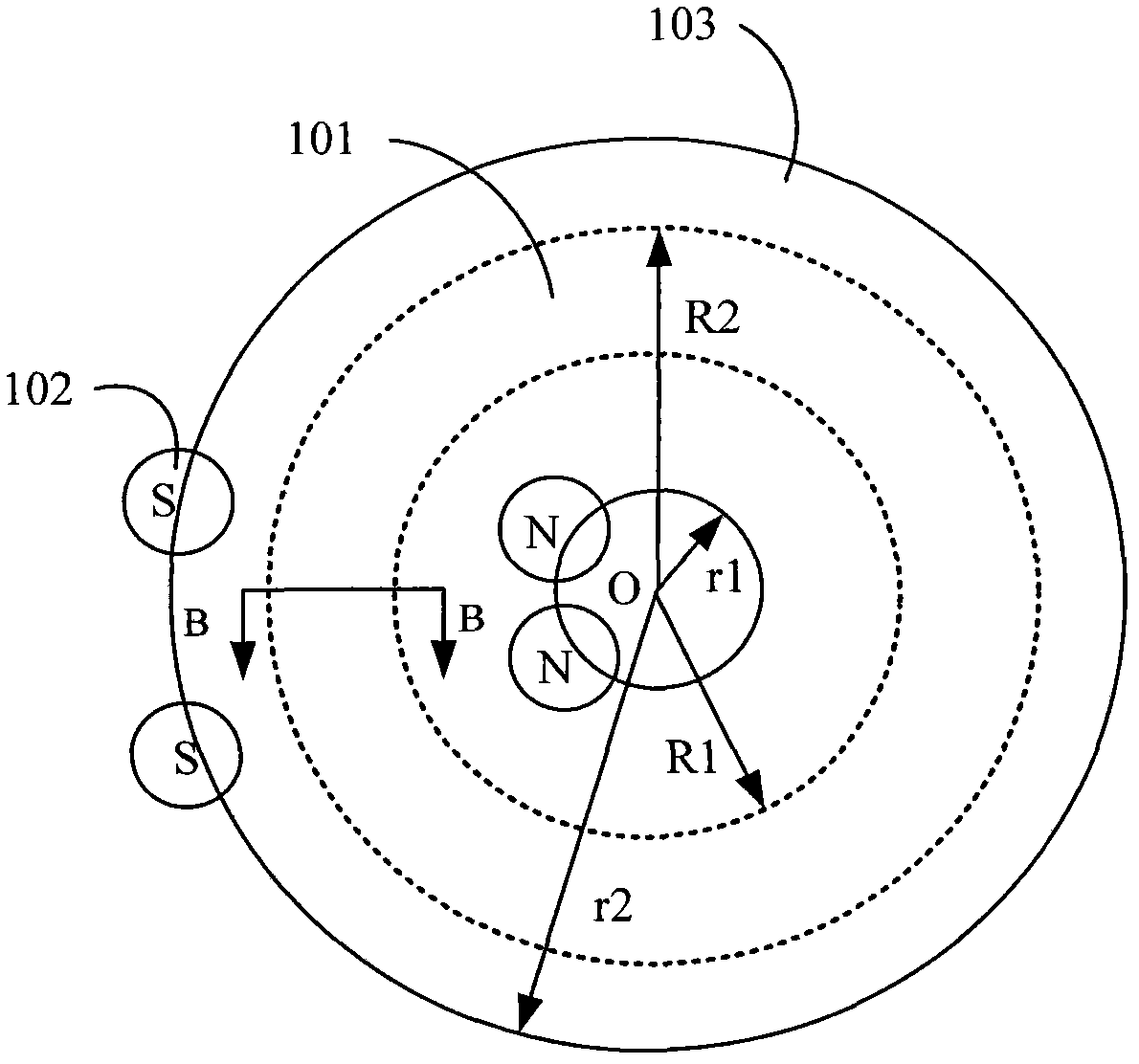

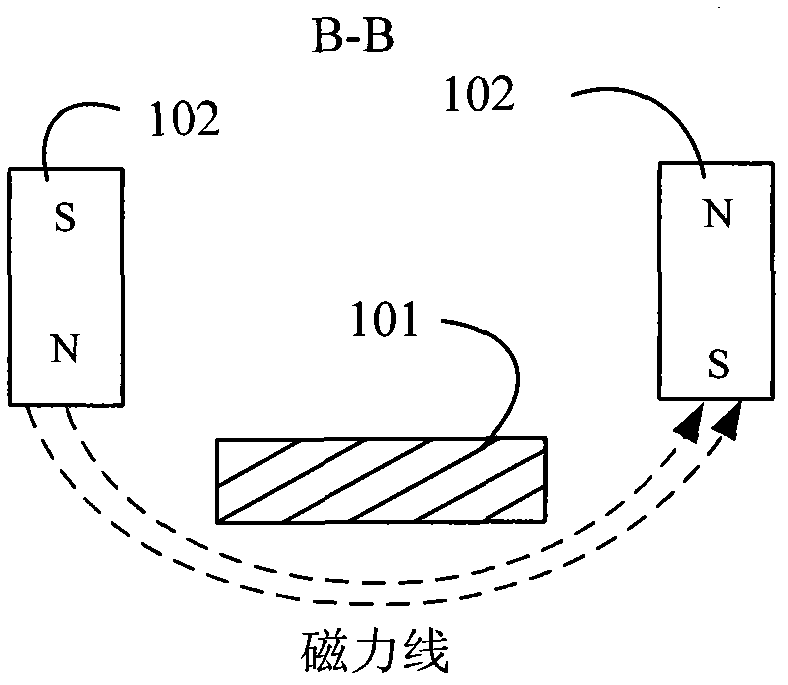

[0032] figure 1 It is a schematic structural diagram of the first specific embodiment of the magnetron sputtering source provided by the present invention. like figure 1 As shown, the magnetron sputtering source according to the embodiment of the present invention includes a target 101, a magnet, a fixing plate 103 and a power source 104; wherein, the magnet is fixedly arranged on the fixing plate 103, and the magnet may include a plurality of magnets 102, and a plurality of magnets 102 Non-uniformly distributed on the fixed plate 103; the target material 101 and the fixed plate 103 are arranged parallel to the central axis, and the target material 101 and the fixed plate 103 can both rotate around their respective central axes. The sputtering surface of the target material 101 and the fixed plate The planes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com