Foam concrete composite board for fireproof isolation belt

A foamed concrete and fire isolation belt technology, applied in fire prevention, building components and other directions, can solve the problems of decreased fire resistance of composite panels, easy contact with fire sources of sandwich polyurethane rigid foam, etc., and achieve the effects of excellent fire resistance and convenient construction.

Inactive Publication Date: 2012-04-04

TIANJIN CHENGJIAN UNIV

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The utility model patent 200820104071.6 relates to a polyurethane rigid foam sandwich integrated thermal insulation lightweight wallboard. A layer of polyurethane rigid foam sandwich layer is poured between two layers of concrete lightweight wallboards to obtain an integrated thermal insulation wallboard. When the patented product is applied to the fire isolation belt, the sandwich polyurethane rigid foam is easy to contact the fire source, which will reduce the fire resistance of the composite board

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

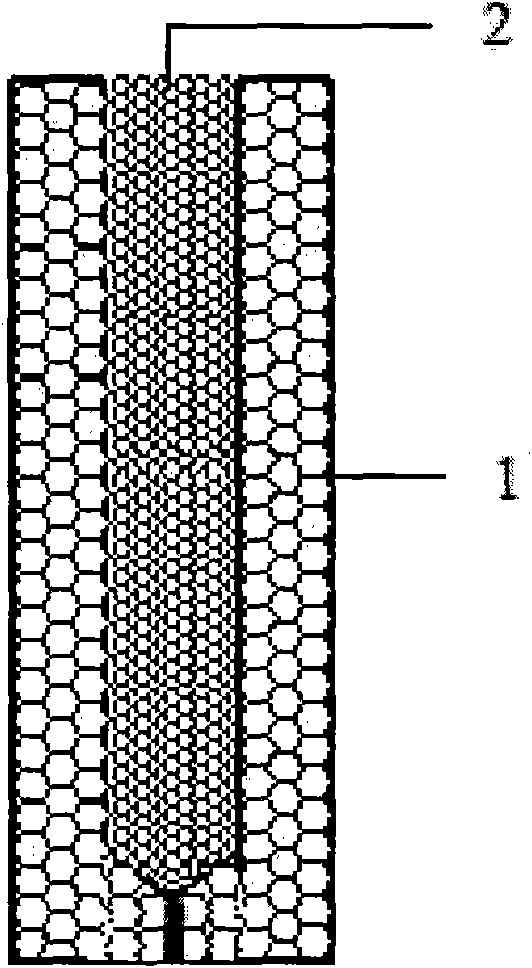

[0011] Example 1: The bulk density of the foamed concrete slab is 150kg / m 3 , the thickness of the sandwich cavity is 20mm, and the overall thickness of the composite panel is 50mm.

Embodiment 2

[0012] Example 2: The bulk density of the foam concrete slab is 300kg / m 3 , the thickness of the sandwich cavity is 30mm, and the overall thickness of the composite panel is 50mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

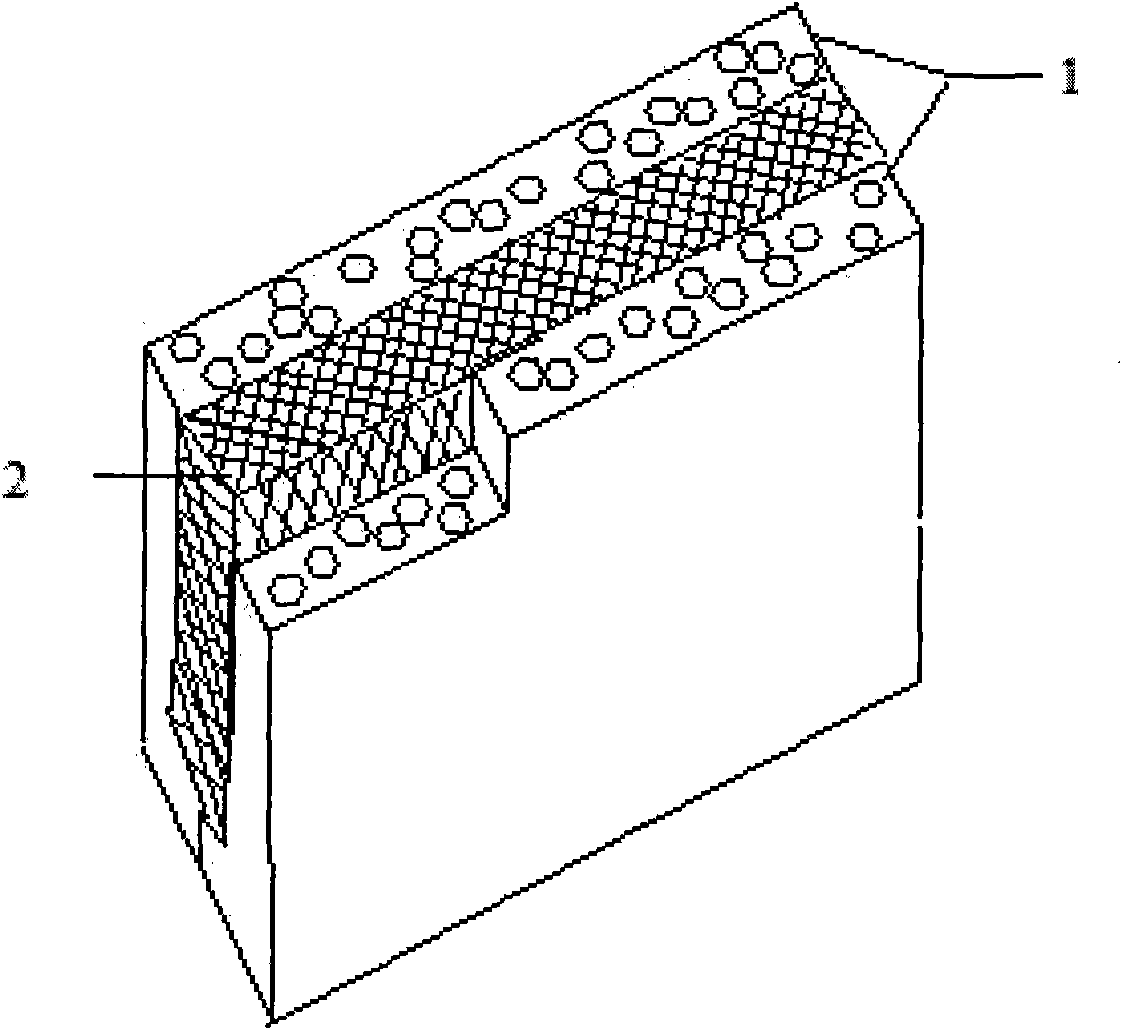

The invention provides a foam concrete composite board for a fireproof isolation belt. The foam concrete composite board is composed of two foam concrete panels and a polyurethane foam sandwich, wherein sections of the two foam concrete panels are L-shaped; the two L-shaped foam concrete panels can be closed to form a mold cavity provided with a closed end, and polyurethane foam can be poured into the mold cavity to form the foam concrete composite board for the fireproof isolation belt; and the foam concrete panels are made of one of a pulverized fuel ash foam concrete sheet material, a slag foam concrete sheet material, a polystyrene granule light-weight foam concrete sheet material, an expanded perlite foam concrete sheet material and s fiber-reinforced foam concrete sheet material. The composite insulation board has the advantages of excellent fireproof performance, light weight, thermal insulation, low cost and good durability, can be produced into composite boards of different volume weights, and is applicable to the fireproof isolation belt for an external wall of a building.

Description

technical field [0001] The invention belongs to the field of building materials, in particular to a foam concrete composite board for a fireproof isolation belt. Background technique [0002] The existing building insulation boards are mainly organic polystyrene boards, which have poor fire resistance and potential safety hazards. In the actual construction process, it is necessary to set up a fire barrier. The traditional fire barrier materials are mainly rock wool, inorganic thermal insulation mortar, polyphenolic foam, etc. These materials have disadvantages such as high price, complicated construction technology or insufficient durability. [0003] Utility model patent 200820104071.6 relates to a polyurethane rigid foam sandwich integrated thermal insulation lightweight wallboard. A layer of polyurethane rigid foam sandwich layer is poured between two layers of concrete lightweight wallboards to make an integrated thermal insulation wallboard. When the patented product ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/94

Inventor 李军伟

Owner TIANJIN CHENGJIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com