Heating and heat supply cogeneration steam turbine

A combined heat and power, heating and heating technology, applied in the field of steam turbines, can solve the problems of low efficiency, small transfer torque capacity of journals, and low heat supply, and achieve simple operation and maintenance, strong safety assurance, and high heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

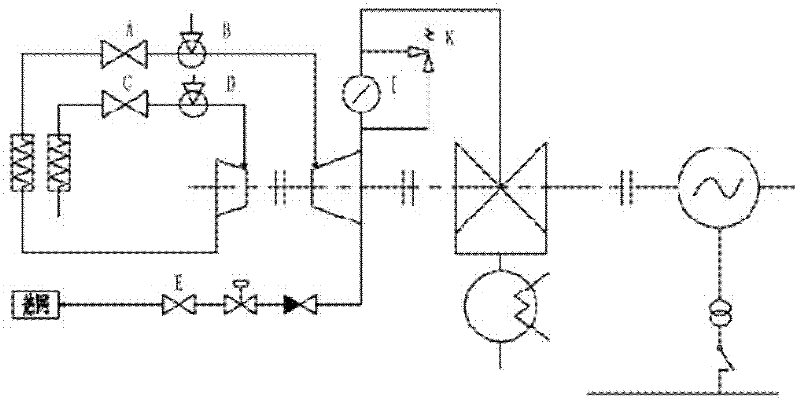

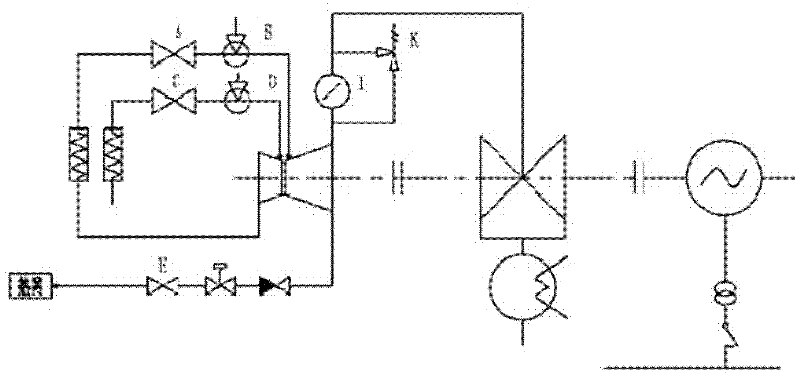

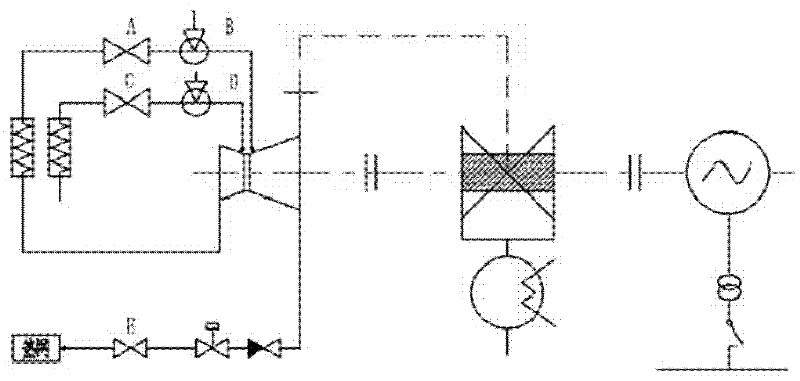

[0044] In the technical solution of the present invention, the low-pressure rotor of the steam turbine is used alternately with the drive shaft to realize steam condensation or back pressure operation of the steam turbine.

[0045] ——overall plan

[0046] The non-heating period remains unchanged, and the low-pressure rotor is replaced with a transmission shaft during the heating period. During the heating period, the high and medium voltage rotors are directly connected to the generator rotor through the transmission shaft, and the low pressure part is removed from the flow and the low pressure heater is turned off.

[0047] The 1#, 2#, 3# low-pressure heaters of the main thermal system of the steam turbine were cut off.

[0048] In terms of heating configuration, it is necessary to increase the heating network heater.

[0049] ——Main parameters (thermal parameters, overall layout and structural dimensions)

[0050] Inlet steam parameters: no change

[0051] Exhaust parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com