Travelling wave tube collector needle and processing technology thereof

A processing technology and collector technology, which is applied in the field of microwave vacuum electronic components, can solve the problems of difficult processing, application restrictions, high processing requirements, etc., and achieve the effect of meeting technical requirements and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

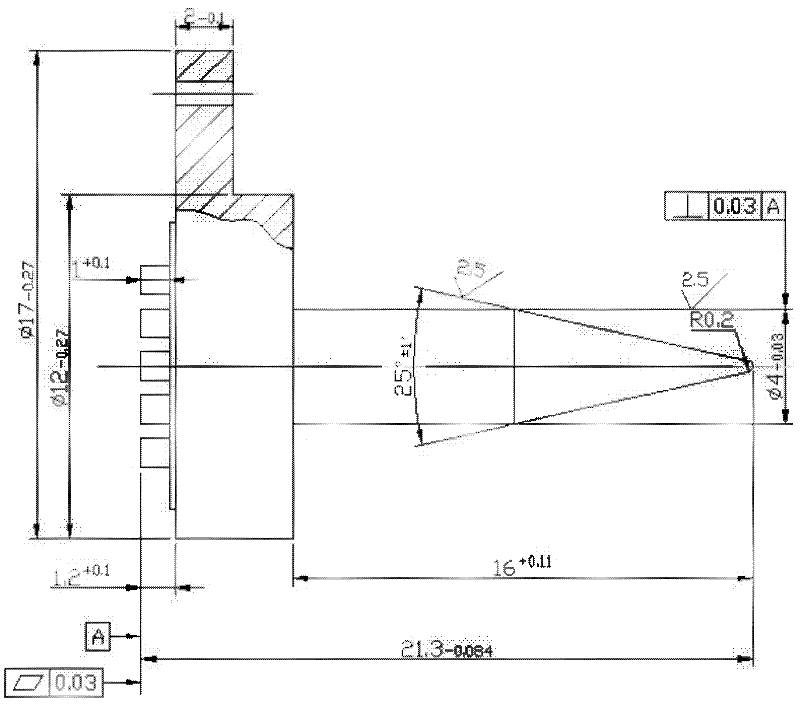

[0059]The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0060] The following dimensions are in mm unless otherwise specified.

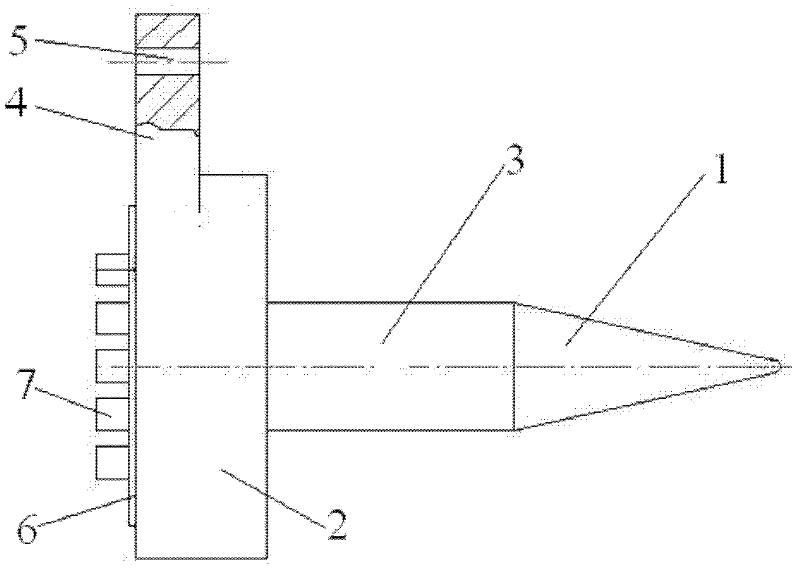

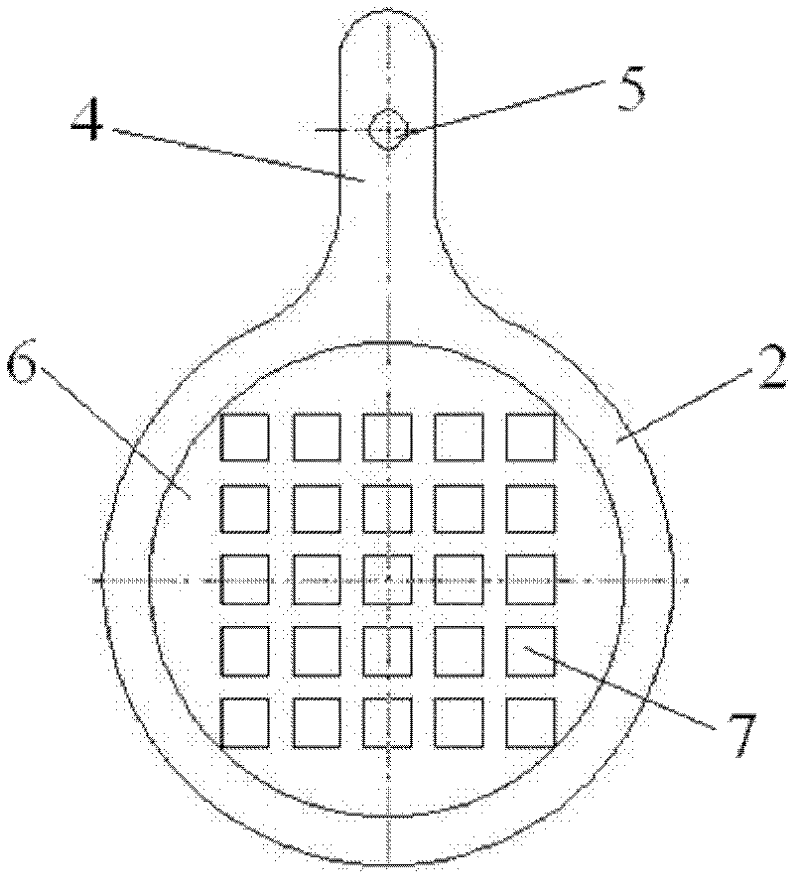

[0061] Such as figure 1 , figure 2 According to the structure of the present invention, the present invention is a collector needle of a traveling wave tube, and the material of the collector needle of a traveling wave tube is oxygen-free copper TU1.

[0062] Such as Figure 1 to Figure 4 As shown, the structure of the collector needle of the traveling wave tube is:

[0063] One end of the main body of the traveling wave tube collector needle is a cone 1 with the tip at the end, and the other end of the traveling wave tube collector needle is a large-diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com