Hollow fiber membrane filter performance testing device

A filtration performance test and fiber membrane technology, which is applied in the field of membrane separation process, can solve the problems of large differences, inability to accurately characterize and evaluate the performance of hollow fiber membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

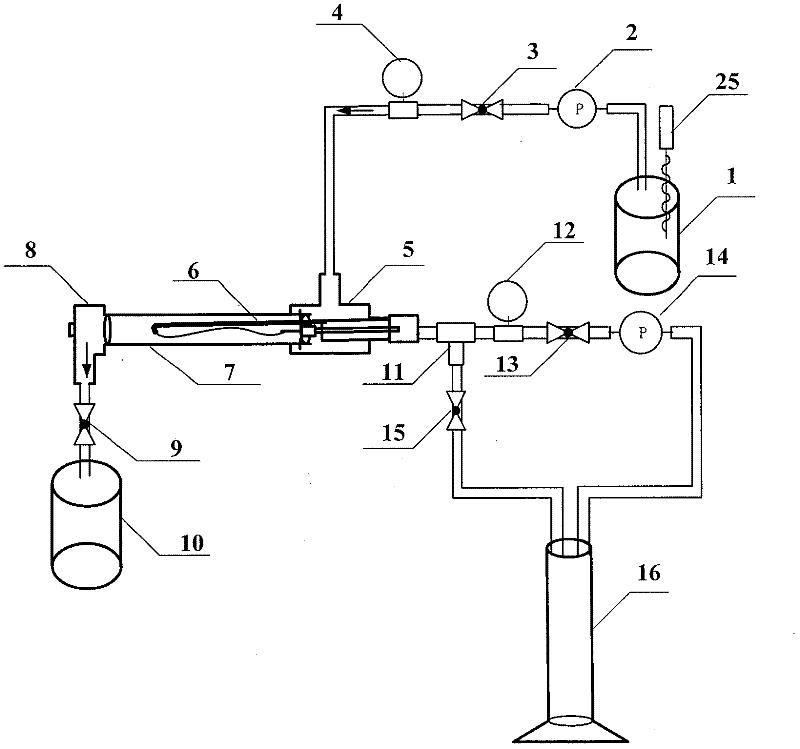

[0015] A hollow fiber membrane filtration performance testing device includes a membrane fiber filter element (6), a cylindrical membrane filter container (7), a membrane filter pump (2, 14), a pressure regulating valve (3, 9, 15), positive and negative pressure Table (4, 12), water distribution tank (1) for filtrate, temperature controller (25), filtered liquid collecting measuring cylinder (16).

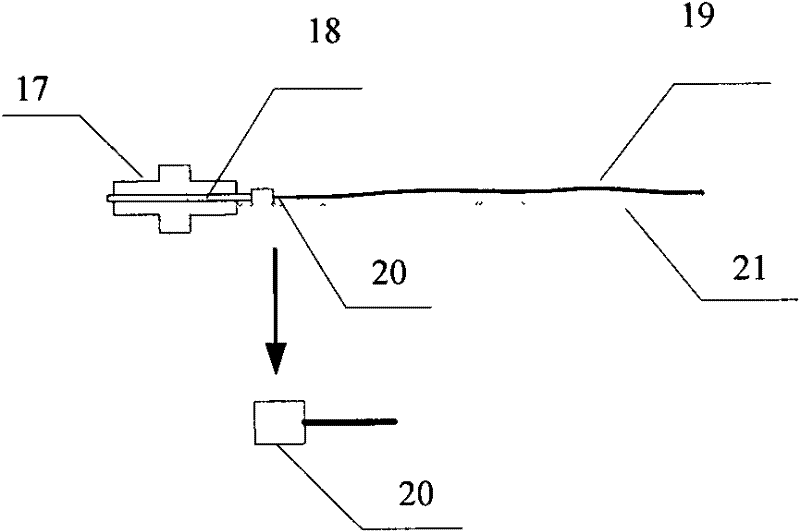

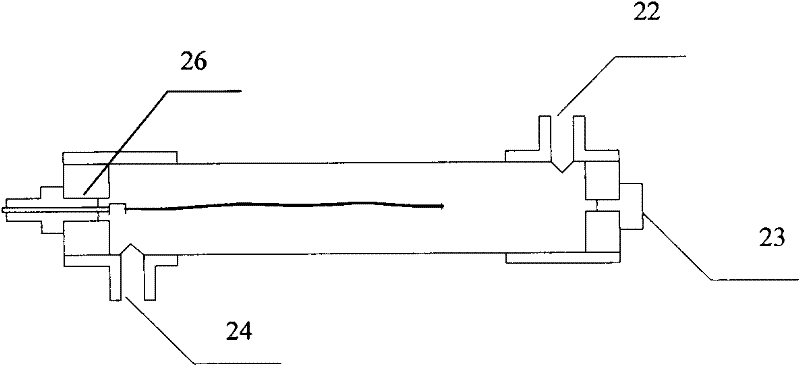

[0016] The core part of a hollow fiber membrane filtration performance testing device is a membrane fiber filter container, which consists of a cylindrical filter container (7), a membrane fiber filter element (6), an external threaded joint (17), an internal threaded joint (26), It consists of a hollow tube (18), a test membrane fiber (19), a capillary joint (20), a capillary joint (20), and a membrane fiber support frame (21). The membrane fiber filter element (6) is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com