Continuous liquid preparation device for high flow concentrated liquid and control system thereof

A technology of concentrated liquid and large flow, which is applied in the direction of mixer accessories, dissolving machines, mixers, etc., which can solve the problems of poor quality of dosing, poor mobility of dosing equipment, slow dosing speed, etc., achieve high-speed communication and ensure real-time performance and stability, high-speed error detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

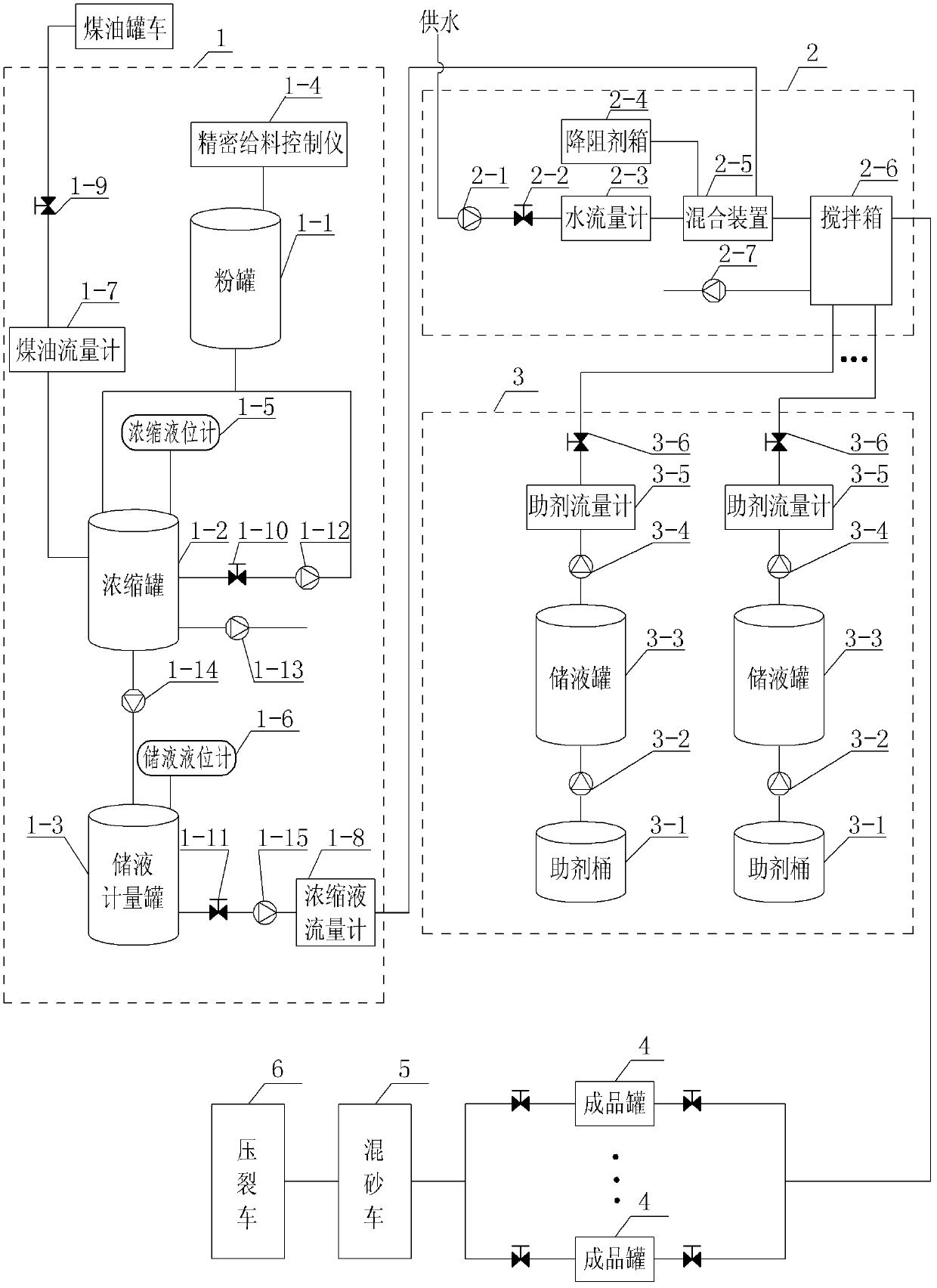

[0032] Specific implementation mode one: the following combination figure 1 Illustrate this embodiment, the large-flow concentrated liquid continuous dosing device described in this embodiment includes a concentrated liquid compartment 1, a thickening compartment 2, an auxiliary agent compartment 3 and n finished product tanks 4, and the concentrated liquid compartment 1 receives the oil from the kerosene tanker. Kerosene, the concentrated liquid output from the concentrated liquid compartment 1 is sent to the thickening compartment 2, the thickening compartment 2 receives the clean water provided by the water supply source, the thickening compartment 2 receives various additives provided by the auxiliary compartment 3 at the same time, and the thickening compartment 2 outputs the distribution good liquid to finished tank 4;

[0033] The concentrated liquid compartment 1 includes a powder tank 1-1, a concentrated tank 1-2, and a liquid storage metering tank 1-3. The powder out...

specific Embodiment approach 2

[0038] Specific embodiment two: this embodiment will further explain embodiment one, the concentrated liquid compartment 1 also includes a precision feeding controller 1-4, a concentrated liquid level gauge 1-5, a liquid storage level gauge 1-6, and a kerosene flow meter 1-7. Concentrate flowmeter 1-8, kerosene delivery valve 1-9, concentrate circulation valve 1-10, concentrate delivery valve 1-11, concentrate circulation pump 1-12, concentrate pouring pump 1 -14 and concentrated liquid delivery pump 1-15,

[0039] The powder tank 1-1 is equipped with a precision feeding controller 1-4, which is used to measure and control the powder feeding amount of the powder tank 1-1;

[0040] A concentrated liquid level gauge 1-5 is arranged on the concentrated tank 1-2 for measuring the liquid level of the concentrated tank 1-2;

[0041] A liquid storage level gauge 1-6 is arranged on the liquid storage metering tank 1-3 for measuring the liquid level of a given liquid storage metering ...

specific Embodiment approach 3

[0046] Specific embodiment three: this embodiment will further illustrate embodiment one or two, the concentrated liquid compartment 1 also includes a concentrated liquid raffinate pump 1-13, and the concentrated liquid raffinate pump 1-13 is arranged on the side of the concentration tank 1-2 On the outlet pipeline at the position where the wall is close to the bottom, it is used to discharge the raffinate of the concentration tank 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com