Liquid material automatic feeding system

A technology of automatic feeding and liquid material, applied in the direction of using electric device flow control, etc., can solve the problems of poor corrosion resistance and easy damage of the diverting device, personnel safety, no remote network access connection, etc., to improve the feeding efficiency and correctness, solve the problem The effect of slow feed pump speed and simple washing program settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

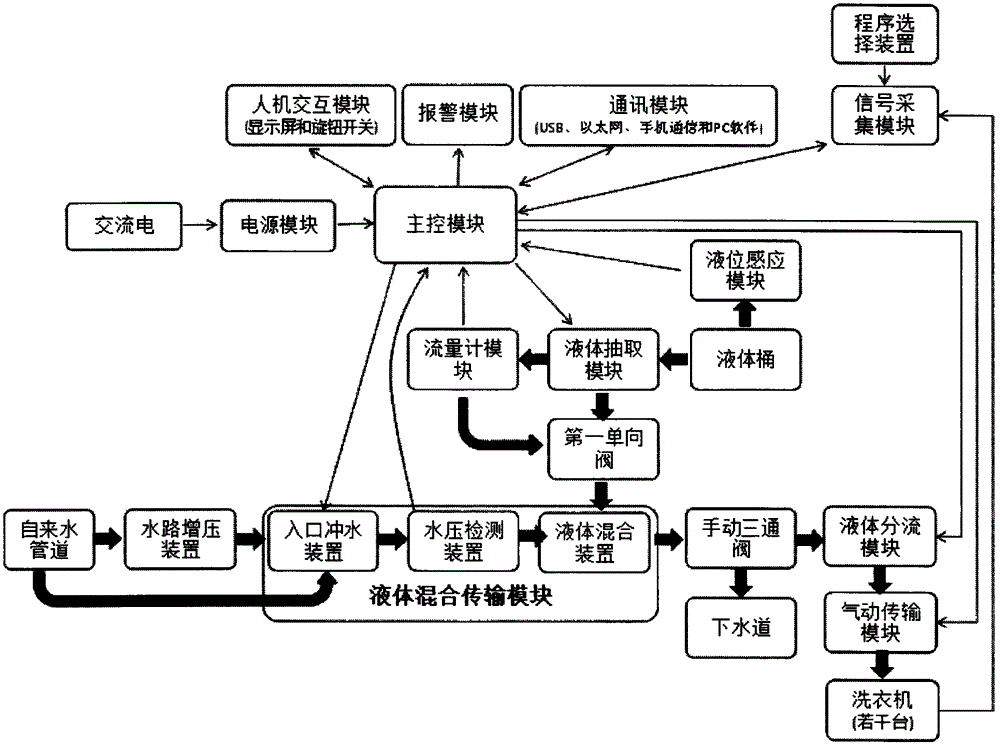

[0033] See figure 1 , an embodiment of the present invention provides an automatic feeding system for liquid materials, including a signal acquisition module, a liquid extraction module, a liquid mixing and transmission module, a liquid distribution module, a communication module and a main control module, wherein:

[0034] The signal acquisition module is used to collect the feeding signal output by the equipment to be fed and send the feeding signal to the main control module;

[0035] The liquid extraction module includes several liquid barrels for containing liquid and several liquid extraction devices corresponding to the liquid barrels, and the liquid extraction module is used to extract a specified amount of one or more liquids from the The liquid is extracted from the barrel and sent into the liquid mixing transmission module;

[0036] The liquid mixing transmission module is used to receive the liquid sent by the liquid extraction module and mix it when receiving mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com