Sodium borohydride alcoholysis hydrogen production multi-bed reaction device

A technology of sodium borohydride alcohol and sodium borohydride is applied in the field of fuel cell reaction devices, which can solve the problems of affecting the personal safety of equipment, increasing the difficulty of controllable hydrogen production, and increasing the temperature of the reaction solution, so as to reduce the cost of precious metals and the amount of hydrogen production. Precisely controllable, normal operating temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

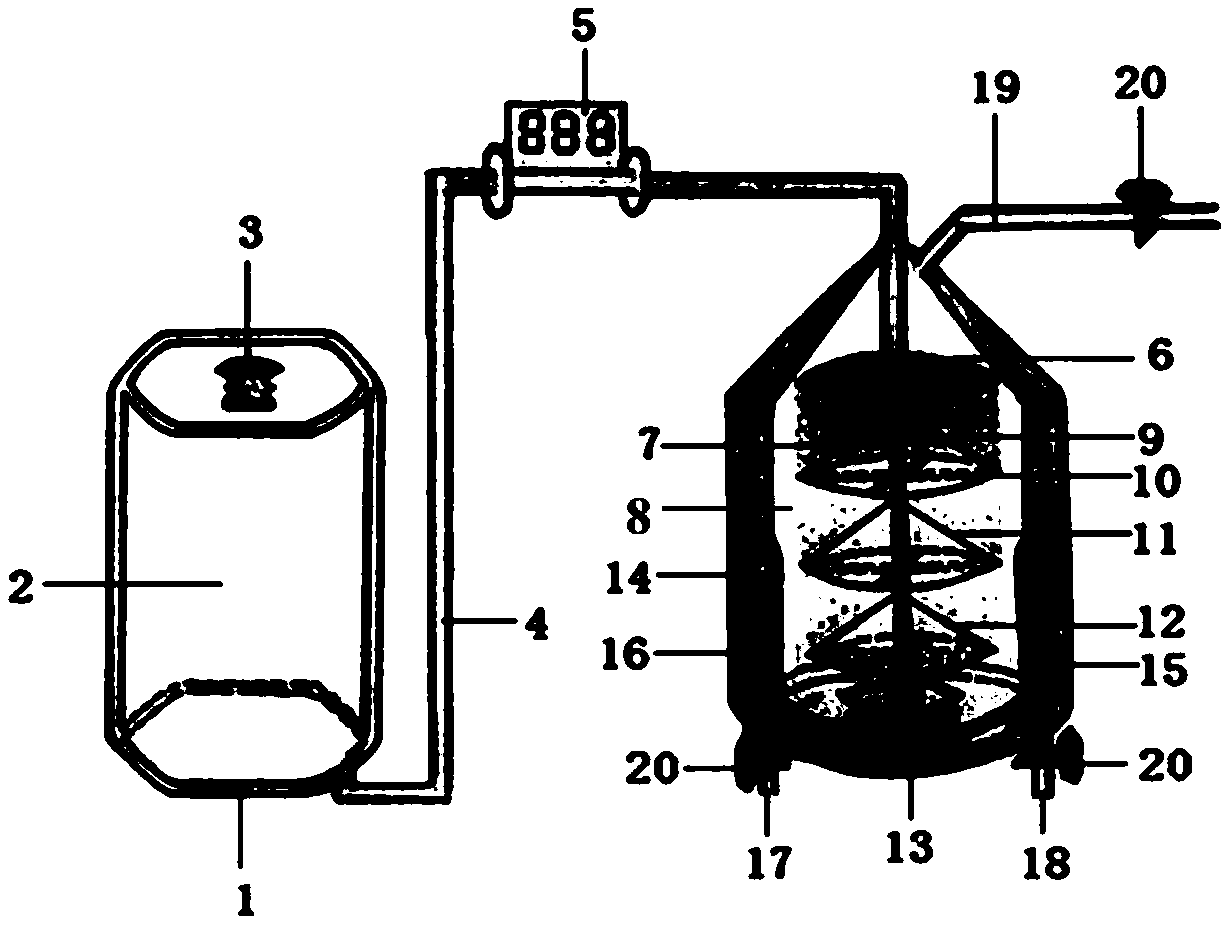

[0040] see figure 1 , the present invention discloses a multi-bed reaction device for producing hydrogen by alcoholysis of sodium borohydride, which mainly includes a sodium borohydride liquid storage tank (sodium borohydride methanol solution liquid storage tank) 1, a flow controller 5, a sprayer (atomizer ) 6, multi-stage catalyst reaction bed, heat exchanger, by-product collection tank 14.

[0041] The sodium borohydride storage tank 1 is used to store alkaline sodium borohydride methanol solution (alkaline sodium borohydride methanol solution 2), and the sodium hydroxide solution is mixed with the sodium borohydride methanol solution to suppress the autoalcoholysis reaction. The storage device has good heat insulation from the external environment, which prevents the sodium borohydride methanol solution from producing hydrogen due to alcoholysis due to the increase in the external environment temperature, resulting in high pressure in the liquid storage tank. The liquid s...

Embodiment 2

[0048] figure 1 The multi-bed reaction device for hydrogen production based on alcoholysis of sodium borohydride is composed of sodium borohydride liquid storage tank, flow controller, sprayer, multi-stage catalyst reaction bed, heat exchanger, by-product collection tank and other parts. From top to bottom, the first layer of catalyst is foamed nickel-supported Ru catalyst, the second and third layers are carbon cloth-supported CoB catalysts, and the amount of catalyst in each layer is 2g, using sodium borohydride 5wt.% and sodium hydroxide 3wt.% methanol solution is used as reactant, and at 50℃, the flow rate of hydrogen production is 3.2L / min when the steady state is reached.

Embodiment 3

[0050] figure 1 The multi-bed reaction device for hydrogen production based on alcoholysis of sodium borohydride is composed of sodium borohydride liquid storage tank, flow controller, sprayer, multi-stage catalyst reaction bed, heat exchanger, by-product collection tank and other parts. From top to bottom, the first layer of catalyst is activated carbon-supported Pt catalyst, the second layer is foam nickel-supported Ru catalyst, and the third layer is carbon cloth-supported CoB catalyst, using sodium borohydride 5wt.% and sodium hydroxide 3wt.% The methanol solution is the reactant, and the amount of catalyst in each layer is 2g. Under the condition of 0°C, the flow rate of hydrogen production is 1.5L / min when the steady state is reached.

[0051] In summary, the multi-bed reaction device for hydrogen production by alcoholysis of sodium borohydride proposed by the present invention uses a flow controller to accurately control the quality and flow rate of reactants, improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com