Deep dewatering method for sludge

A technology of deep dewatering and sludge dewatering, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low utilization rate and restrict wide application, so as to improve dewatering performance, cheap and easy to obtain chemicals, and is conducive to the follow-up. effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

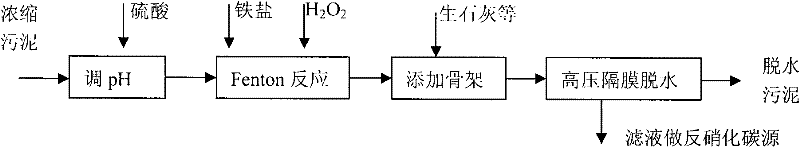

[0016] A method for deep dehydration of sludge, which method specifically includes the following steps:

[0017] a. Adjust the pH of the concentrated sludge to about 3 with acid, generally 2.5-3.5. The acid used is dilute sulfuric acid, and other acidic industrial raw materials can also be used; biological acidification is not recommended because it induces new The formation of microbial flora is not conducive to subsequent dehydration.

[0018] b. Add Fe-containing at a weight ratio of 0.1 to 0.3% of the dry weight of the sludge 2+ Or Fe 3+ Iron salt, Fe 2+ And Fe 3+ The conditioning effects of iron salts are not very different. Add H at a weight ratio of 1 to 3% of the dry weight of the sludge 2 O 2 Or peracetic acid; stir quickly at a speed of 100~200rpm for 1~3min, and stir at a speed of 10~30rpm for 20~40min. The higher the temperature, the same conditioning effect will be obtained. The consumed H 2 O 2 Or the less peroxyacetic acid; but the heating cost is higher, and it is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com