Microstrip antenna composite substrate material and preparation method thereof

A composite substrate and microstrip antenna technology, applied in the field of composite substrate materials and their preparation, can solve the problems of low cut-off frequency and inability to use antenna substrates, and achieve the effects of reducing weight and volume, increasing bandwidth, and expanding antenna bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A microstrip antenna composite substrate material is compounded by 80 parts by mass of a main phase material and 20 parts by mass of an auxiliary phase material. The main phase material is Co 2 Z-type hexagonal ferrite, its formula molecular formula is Ba 1.5 Sr 1.5 co 2 Fe 24 o 41 ; The auxiliary phase material is polypropylene resin (commercially available brand: Dushanzi Petrochemical EPS30R).

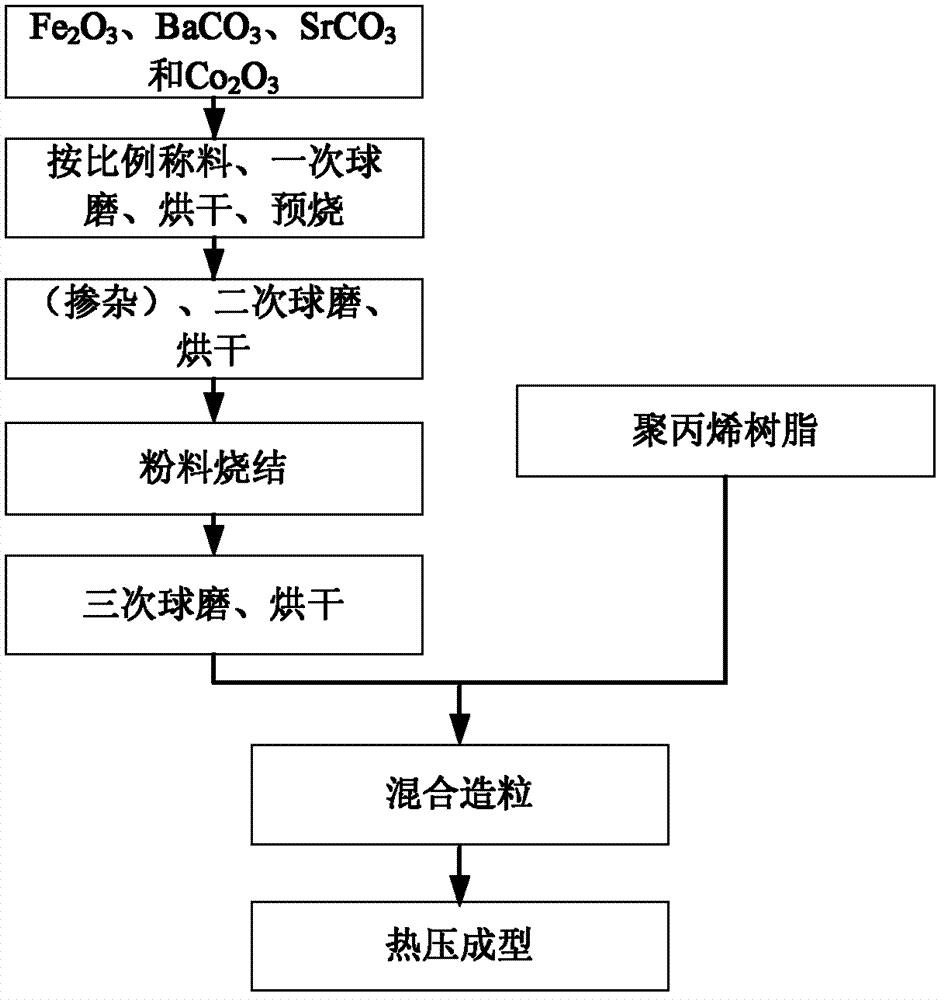

[0026] The specific preparation method of the above-mentioned microstrip antenna composite substrate material is as follows:

[0027] Step 1: Fe 2 o 3 、BaCO 3 , SrCO 3 and Co 2 o 3 As the raw material, convert the mass percentage of various oxides according to the ratio of metal elements in the above ferrite formula molecular formula. After accurate weighing, ball mill in a planetary ball mill for 4 hours at a time. After ball milling, the material is placed in an oven at 100 Dry at ℃.

[0028] Step 2: After sieving the dried material obtained in Step 1, compact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com