Nylon 6 with high performance and low melting-point and preparation method thereof

A low-melting-point, high-performance technology, applied in the field of nylon 6, can solve the problem of low-melting-point nylon 6 performance and achieve the effect of improved comprehensive performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

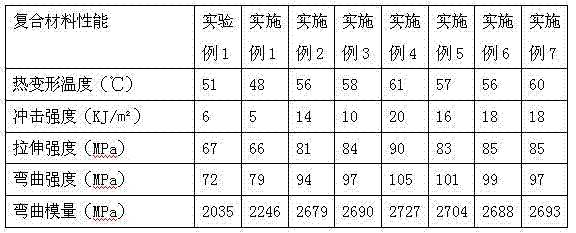

Examples

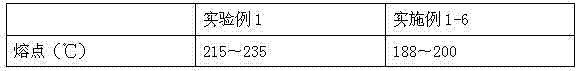

experiment example 1

[0023] Experimental Example 1: Take 92Kg of ordinary nylon 6 (Baling Petrochemical YH800) and dry it at 80°C for 8 hours, and dry 8 Kg of LiCl (Tianjin Kemiou Lithium Chloride Anhydrous) at 140°C for 2 hours, and the dried ordinary nylon 6 and LiCl were extruded and granulated on a co-rotating twin-screw extruder (the rotation speed of the host screw was 240r / min, and the temperatures in the 1st to 7th stages were 205°C, 210°C, 210°C, 215°C, 215°C, 220°C, 225°C, respectively. ℃), the granulated material was dried at 80 ℃ for 4 hours, and then injection-molded on an injection molding machine to obtain high-performance low-melting-point nylon 6.

Embodiment 1

[0024] Example 1: Take 92Kg of ordinary nylon 6 (Baling Petrochemical YH800) and dry it at 70°C for 9 hours, and dry 8 Kg of LiCl (Tianjin Kemiou Lithium Chloride Anhydrous) at 150°C for 1 hour, take the dried ordinary Nylon 6, LiCl, 3kg of epoxy resin and 1kg of other additives are extruded and granulated on a co-rotating twin-screw extruder (the speed of the main screw is 240r / min, and the temperatures of the 1st to 7th stages are 205°C, 210°C, and 210°C respectively , 215°C, 215°C, 220°C, 225°C), the granulated material was dried at 80°C for 4 hours, and injection molded on an injection molding machine to obtain high-performance low-melting point nylon 6.

Embodiment 2

[0025] Example 2: Take 94Kg of ordinary nylon 6 and dry it at 90°C for 7 hours, and dry LiCl 6 Kg at 130°C for 3 hours, take the dried ordinary nylon 6, LiCl, 3kg of epoxy resin and 1kg of other additives in the same direction Extruded and granulated on a twin-screw extruder (the speed of the main screw is 240r / min, and the temperatures of the 1st to 7th stages are 205°C, 210°C, 210°C, 215°C, 215°C, 220°C, 225°C). The material was dried at 80°C for 4 hours, and then injection-molded on an injection molding machine to obtain high-performance low-melting-point nylon 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com