Distributed titanium alloy pipeline electrolytic antifouling apparatus

A titanium alloy tube, distributed technology, applied in the field of electrochemistry to achieve the effects of improving electrolysis efficiency, reducing maintenance workload and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

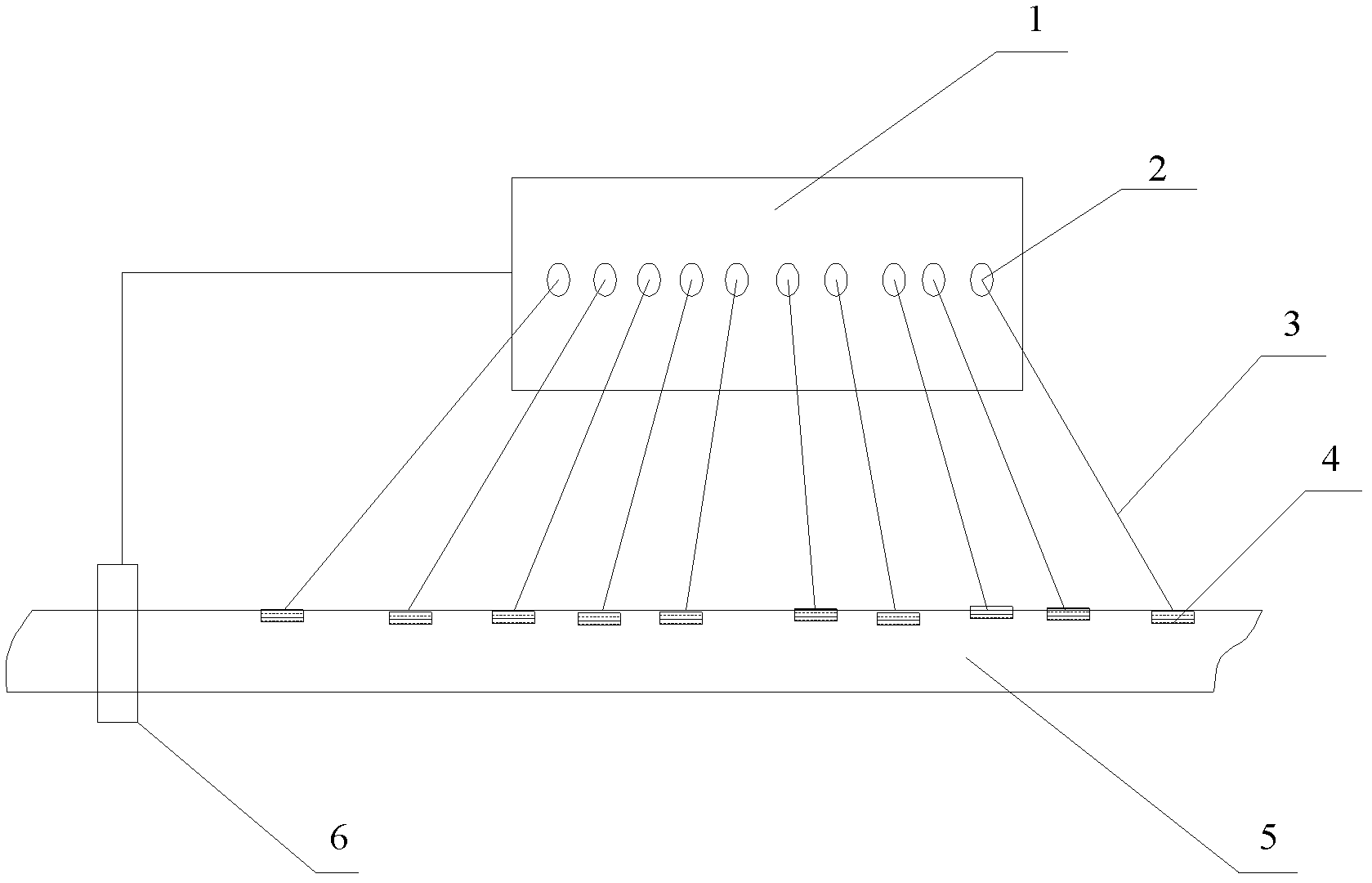

[0012] The distributed titanium alloy pipeline electrolysis antifouling device involved in this embodiment first processes the inner wall of the titanium alloy pipeline 5 to prepare an electrolytic anode 4 capable of electrolyzing seawater to produce effective antifouling agents (such as chlorine gas and hypochlorite); The electrolysis anode 4 is located at the junction of the titanium alloy pipeline 5, and the interval length of the electrolysis anode 4 is determined by the maximum flow of water and the output capacity of the power supply current; the device structure includes a DC power supply 1, an electrolysis anode 4, a flanged cathode 6, a cable 3. The switching element 2 and the titanium alloy pipeline 5 are respectively electrically connected to the positive output terminals of the selected DC power supply 1. Ten switching elements 2 are installed to form ten independent positive voltage output terminals. In the titanium alloy pipeline 5 There are ten electrolytic anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com