Three-dimensional plastic tensile net and manufacturing method thereof

A stretched net and plastic technology, applied in the field of geotechnical reinforced materials, can solve the problems that need to be improved, and achieve the effect of enhancing the effect of soil consolidation and vertical compression resistance, increasing drainage flux, and improving the effect of anti-slump slide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

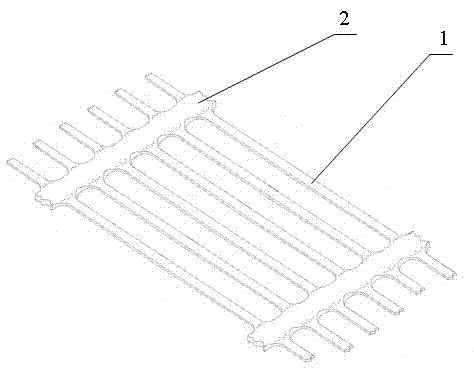

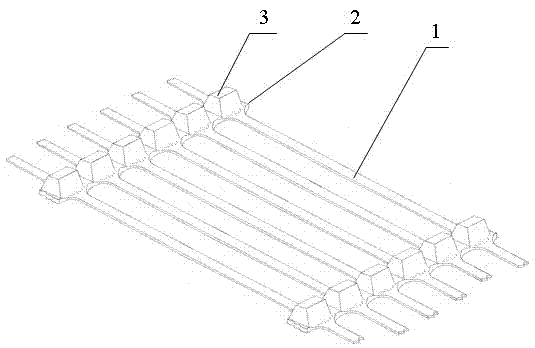

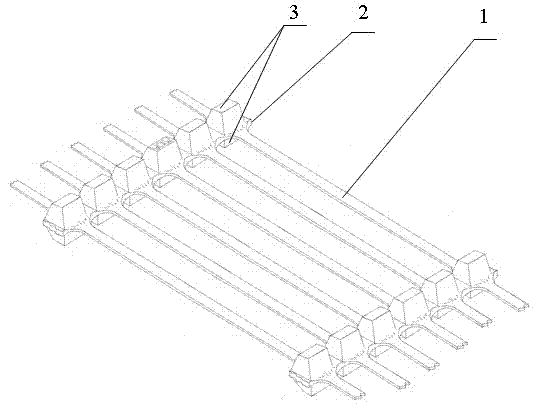

[0047] Embodiment 1: A kind of three-dimensional plastic stretching net, comprises rib, rib and the square, rectangle, circle, ellipse, rhombus, right triangle or equilateral triangle grid hole formed by rib and rib intersecting, its It is characterized in that: on the intersection node of the rib 1 / rib 2 of the unidirectional, bidirectional, three-directional or four-directional three-dimensional plastic stretched net or on the rib 1 / rib 2, there is a fusion with the rib 1 / rib 2 An integral flange, the shape of the flange includes a hemispherical flange, a conical flange, a truncated conical flange, a polygonal pyramid flange, and a pyramidal truncated flange with a polygonal table top. The height of the flange is 3-110mm .

[0048] The flange includes a flange perpendicular to the rib 1 / rib 2, or a flange inclined to the rib 1 / rib 2, or a flange 5 with a curved arc, and the polygonal pyramid flange includes a triangular pyramid flange , a quadrangular pyramid flange and a 5-...

Embodiment 6

[0054] Embodiment 6 is attached Figure 6 Shown: a unidirectionally stretched double-faced rib is provided with a three-dimensional plastic stretch net with a rectangular pyramidal truncated flange on the table surface, and the rectangular pyramidal truncated flange on the mesa continuously penetrates both sides of the rib 2.

Embodiment 7

[0055] Embodiment 7 is attached Figure 7 Shown: The two-roll calender directly forms the initial strip with a single-sided flange, the lower roll is a smooth roll, and the surface of the upper roll is provided with concave holes for pressing the flange, and the plastic extruder is fed between the upper roll and the lower roll The melted plastic, the upper roller rotates clockwise, directly forms the initial strip with a single-sided flange.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Overall density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com