Electromechanical brake and automobile

An electronic mechanical brake and brake caliper technology, applied in mechanical equipment, brake actuators, gear shifting mechanisms, etc., can solve the problems of shortening life, increasing brake volume and cost, and achieving reduced volume and simple structure. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

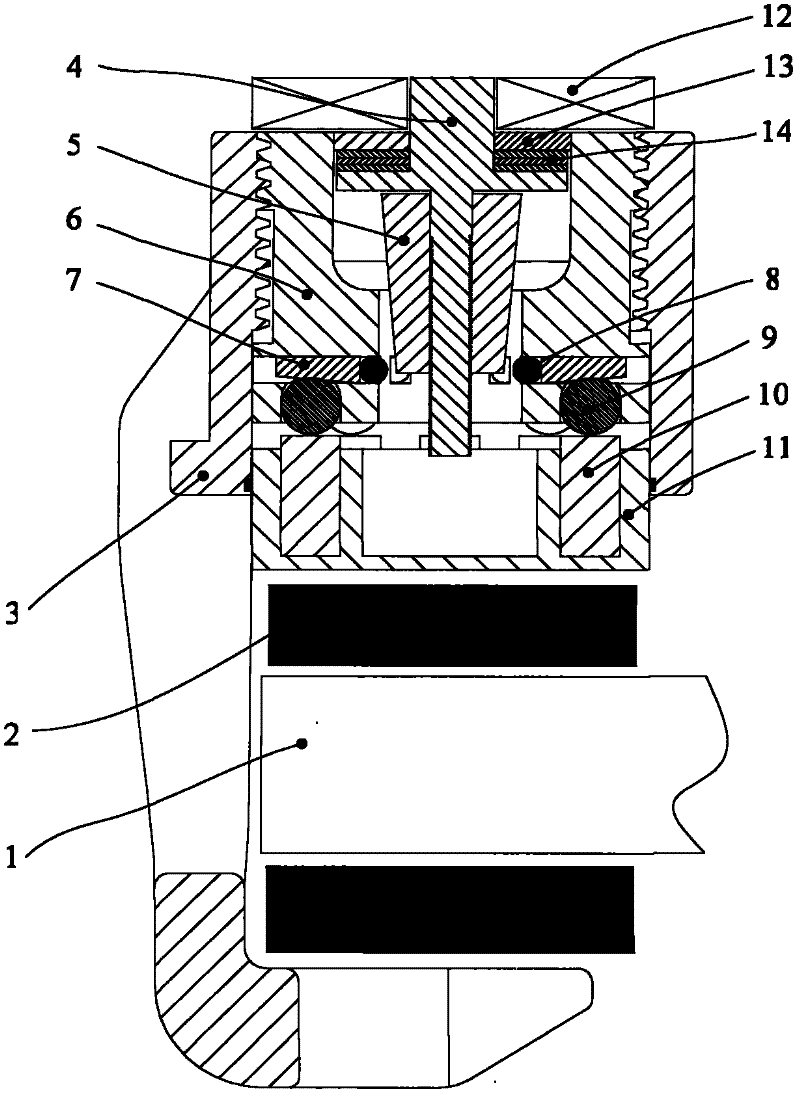

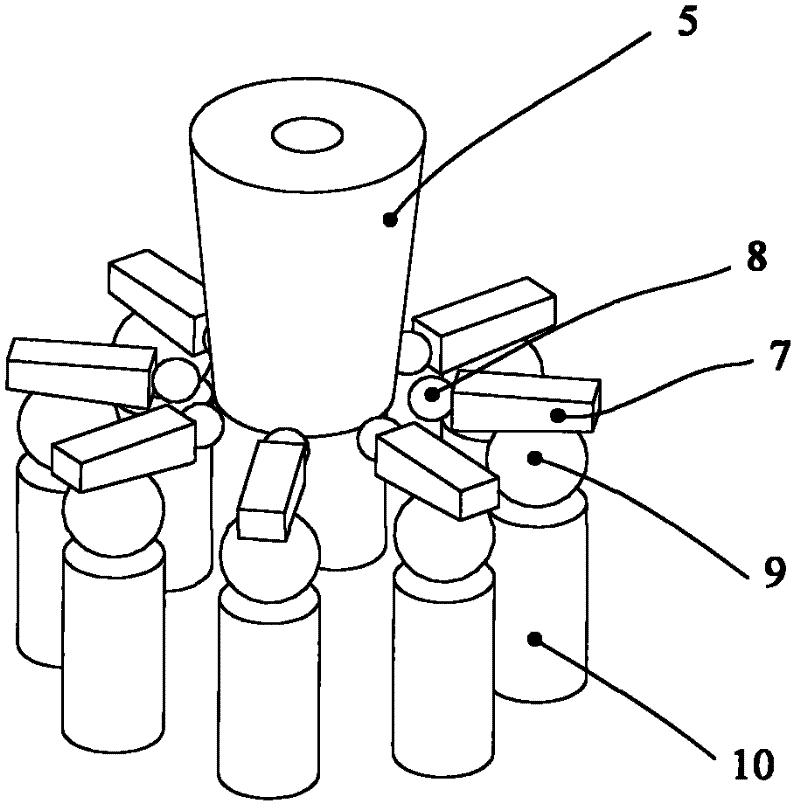

[0028] like figure 1 As shown, in this embodiment, the electromechanical brake includes a brake disc 1 , a friction plate 2 , a brake caliper body 3 , and a power mechanism that can push the friction plate 2 forward to clamp the brake disc 1 .

[0029] Wherein, the power mechanism includes a motor 12, a kinematic mechanism that converts the rotational motion of the motor 12 into a linear motion, a torque booster mechanism that is sleeved on the kinematic mechanism to amplify the torque output by the motor 12, and a torque booster mechanism that is sleeved on the torque booster mechanism and motion The front end of the mechanism and the piston cylinder 11 between the torque booster mechanism and the friction plate 2 .

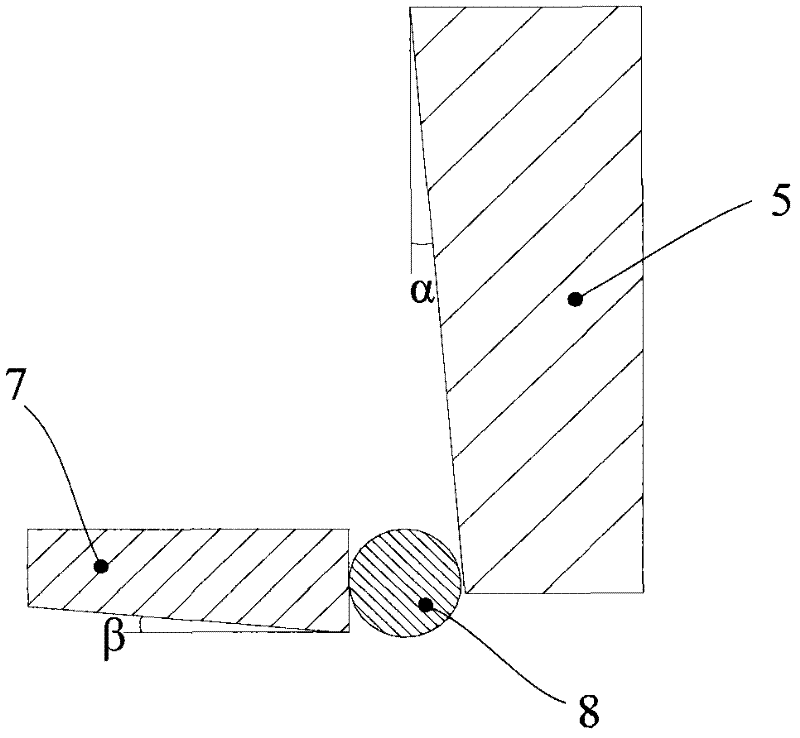

[0030] In this embodiment, the movement mechanism adopts a lead screw mechanism, and the lead screw mechanism includes a lead screw 4 and a first nut 5 sleeved on the lead screw 4. The first nut 5 is an inverted circle with a small front end and a large rear end...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the torque multiplier mechanism of this embodiment does not have the first roller 8 .

[0050] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that this embodiment does not have a piston cylinder 11 , the push rod 10 can directly contact the friction plate 2 , and the push rod 10 is fixedly connected with the corresponding second roller.

[0053] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0054] The electromechanical brake of the present invention reduces the torque on the lead screw 4 due to the arrangement of a torque increasing mechanism with small volume and simple structure, and also avoids setting a deceleration mechanism at the output end of the motor 12, thereby reducing the volume of the electromechanical brake , Save the cost and prolong the service life of the lead screw 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com