Self-excitation retarding device and control method thereof

A retarder, self-excited technology, applied in electromechanical devices, controlling mechanical energy, connecting with control/drive circuits, etc., can solve the problems of difficult installation, high cost, and low output braking torque of the self-excited retarder. The effect of volume and mass reduction, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

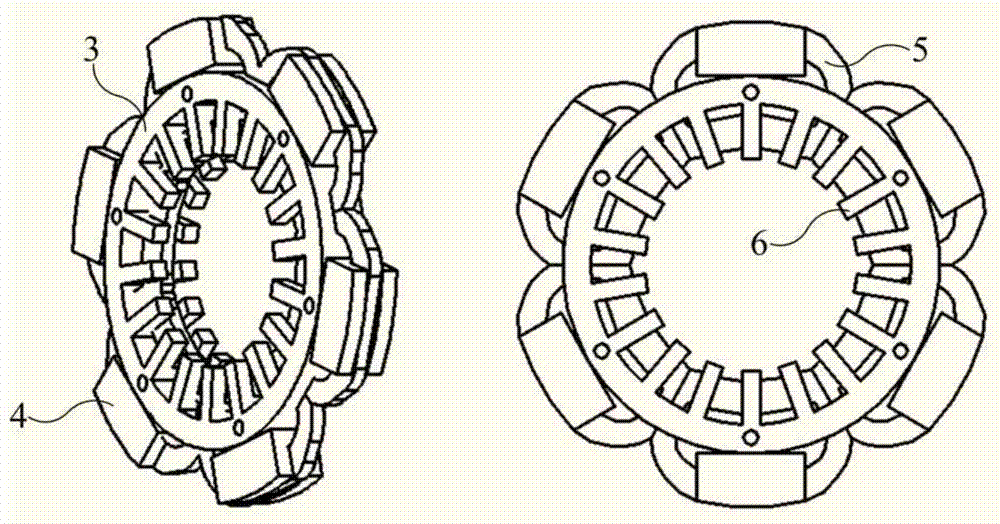

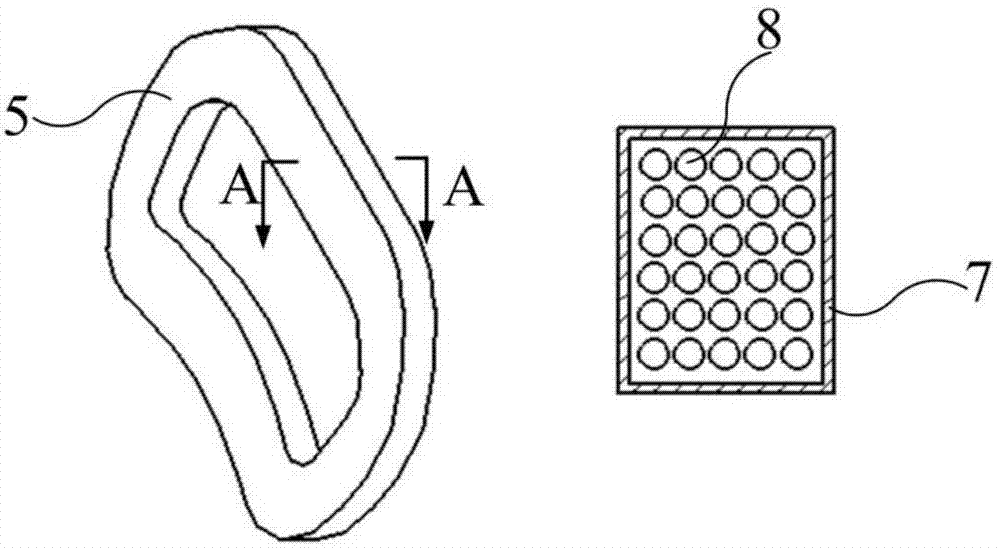

[0031] The structure of the self-excited retarder according to the present invention will be further described below in conjunction with the accompanying drawings. The self-excited retarder includes three parts: stator assembly, rotor assembly and control assembly.

[0032] joint figure 1 , Image 6 and Figure 7 As shown, the self-excited retarder rotor assembly includes an eddy current brake rotor 10 and a generator rotor 11 . The eddy current brake rotor 10 and the generator rotor 11 are coaxially and fixedly connected. Wherein, the rotor 10 of the eddy current brake is connected with the input end of the transmission shaft, and the rotor 11 of the generator is connected with the output end of the transmission. The eddy current brake rotor 10 and the generator rotor 11 rotate synchronously with the automobile drive train.

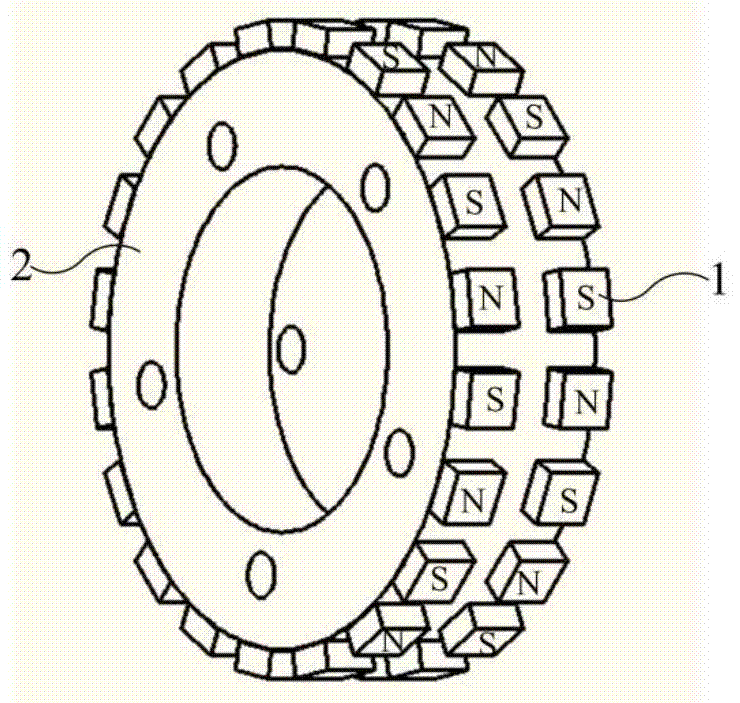

[0033] like figure 1 As shown, the generator rotor 11 includes a generator rotor bracket 2 and several permanent magnets 1 . Two circles of perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com