Brake control method for induction motor

A technology of induction motor and brake control, applied in motor generator control, control system, motor/generator/inverter limiter, etc., can solve problems such as poor braking performance, high cost, and inability to automatically track the maximum braking torque , to achieve high safety and ensure the effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

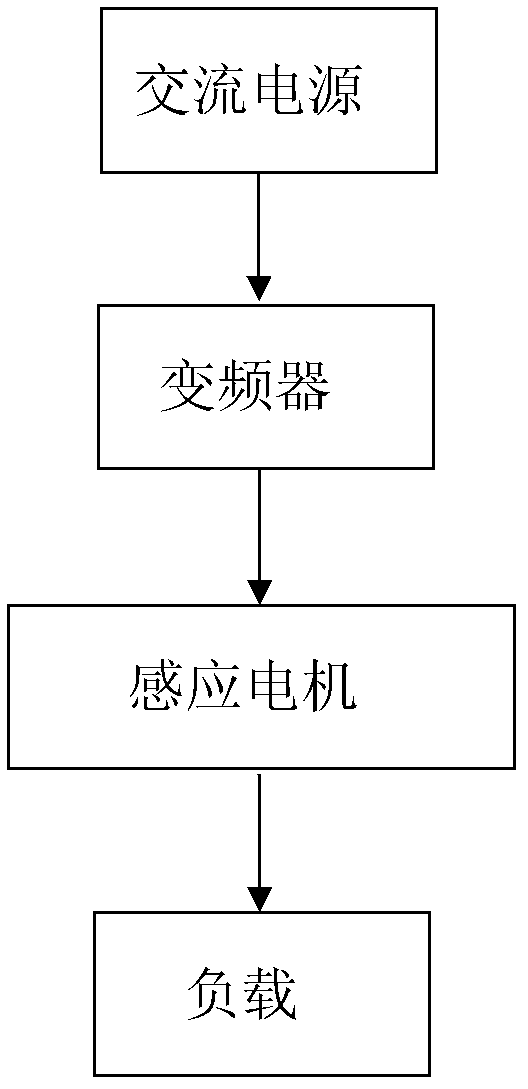

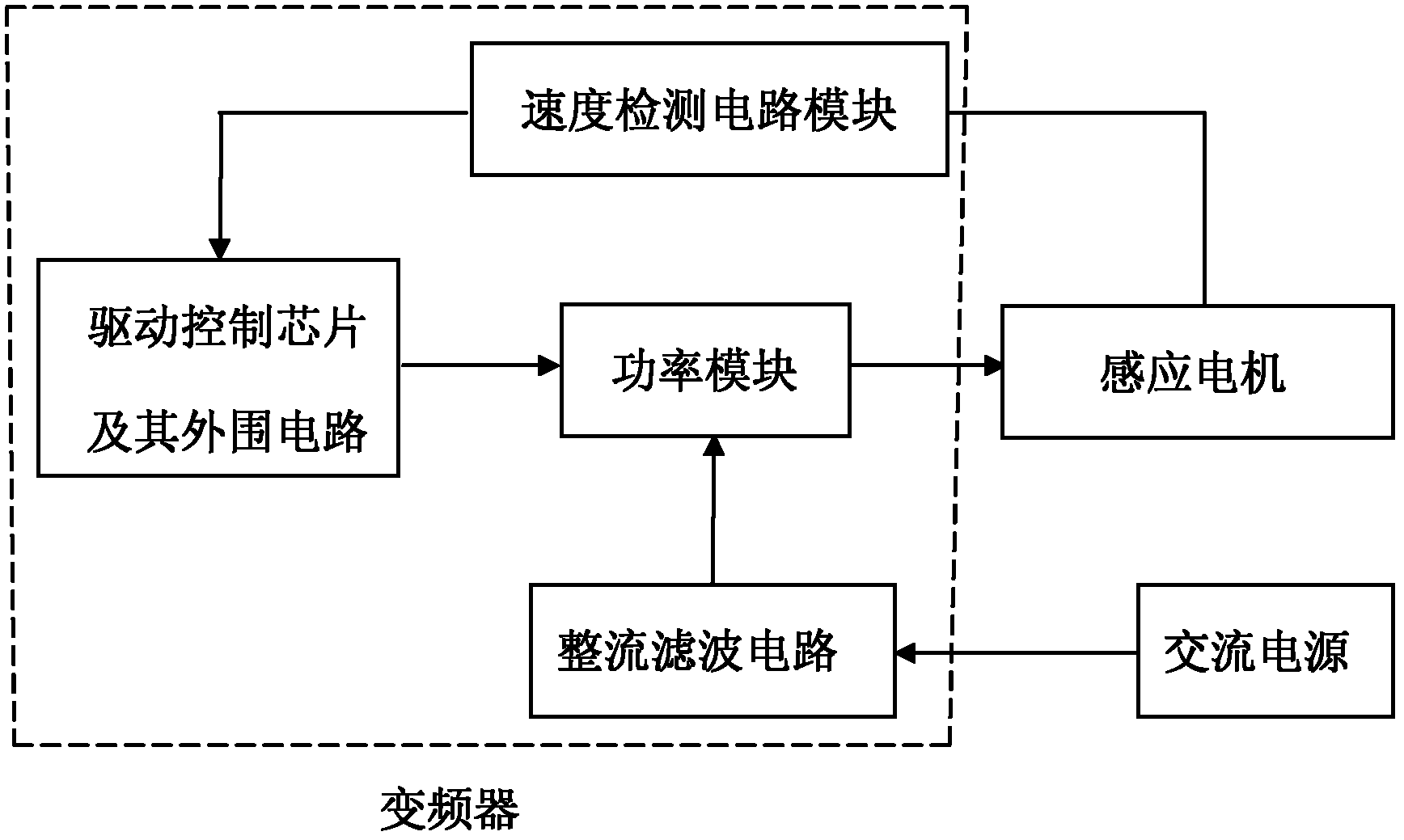

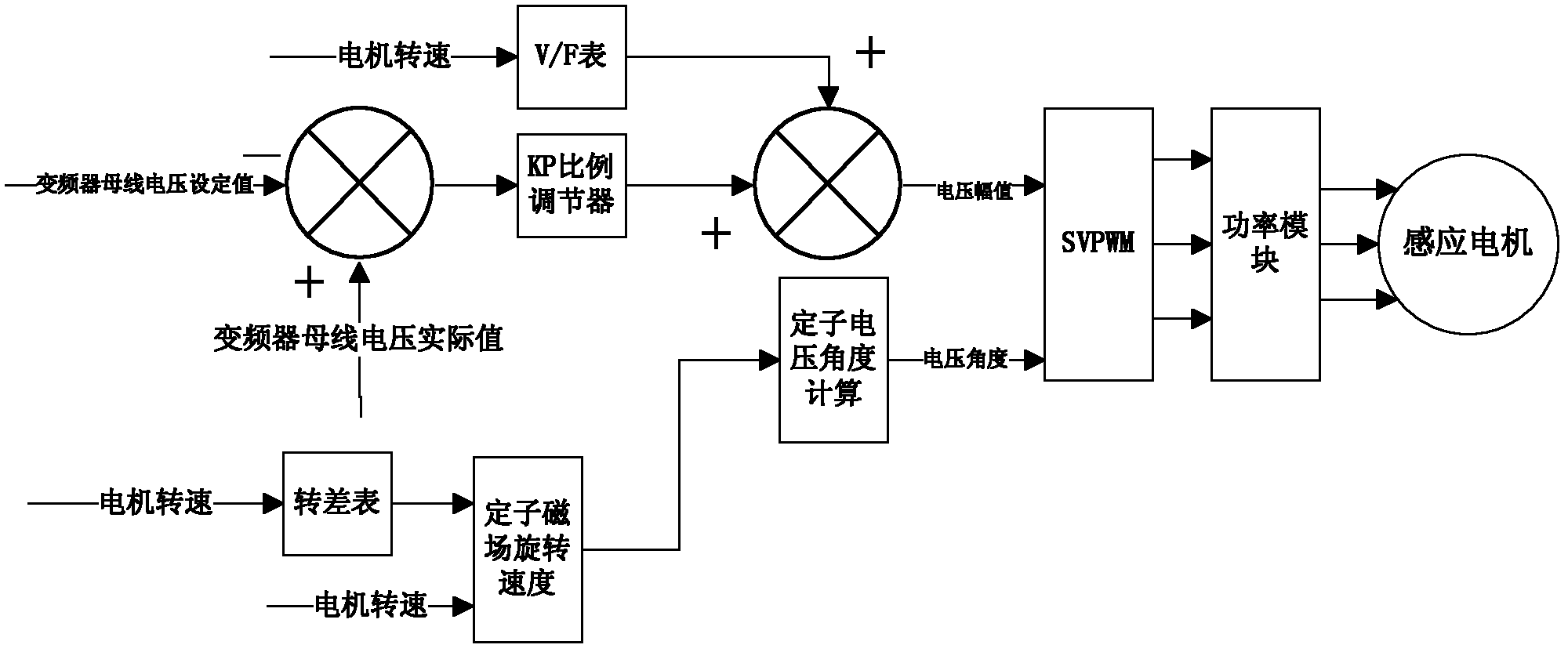

[0030]Such as figure 1 As shown, the application system of the present invention is composed of an AC power supply, a frequency converter, an induction motor and a load connected in sequence, such as figure 2 As shown, the frequency converter includes a rectification and filtering module, a drive control chip and its peripheral circuit modules, a speed detection module, and an IGBT or IPM power module. Controlled by the drive control chip and its peripheral circuits, the drive control chip and its peripheral circuit modules output the PWM signal, and the IGBT or IPM power module converts the PWM signal into a voltage and outputs it to the induction motor. In order to detect the speed of the induction motor in real time, between the induction motor and the drive There is also a speed detection module between the control chip and its peripheral circuit modules, so that the drive control chip and its peripheral circuit modules can carry out a series of protection measures or rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com