Device and method for detecting online plate width of float glass in real time

A technology for real-time detection and float glass, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of increasing manpower, failing to reflect the width and pulling amount of the glass plate in time, and measuring data that cannot objectively reflect the actual state of the glass plate in time and other problems, to achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the embodiments of the drawings:

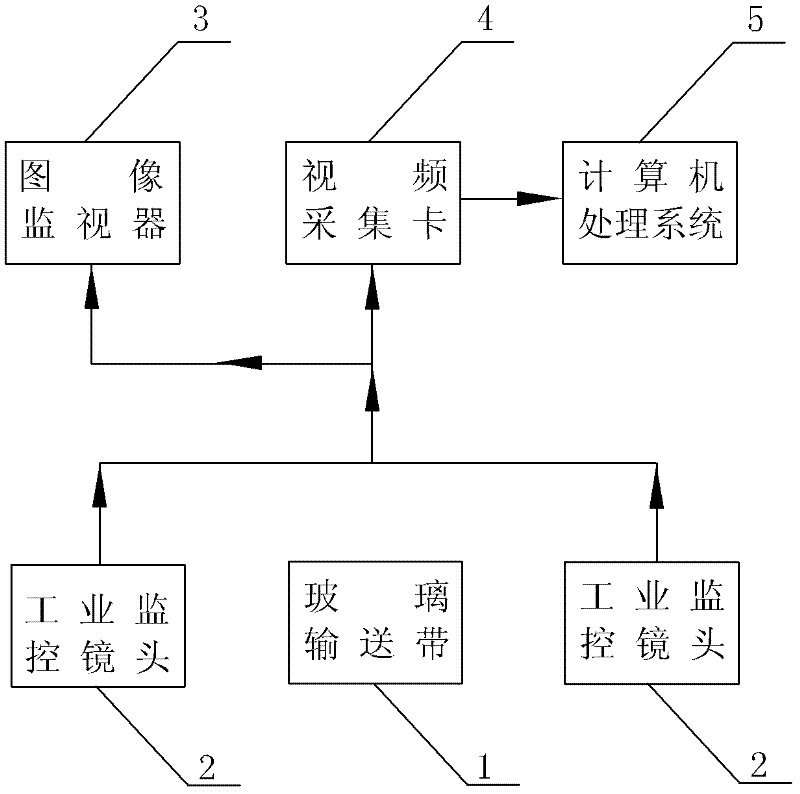

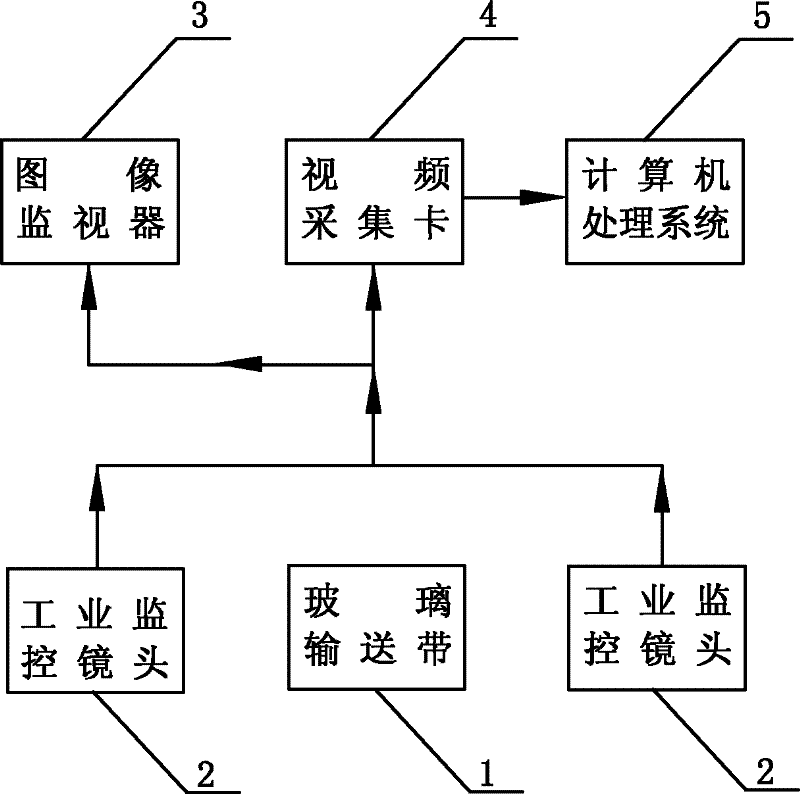

[0014] Such as figure 1 , 2 As shown, the float glass on-line real-time detection device for plate width includes a glass conveyor belt 1. On both sides of the edge of the glass conveyor belt 1, an industrial monitoring lens 2 is respectively set, and the imaging range of the industrial monitoring lens 2 covers the glass plate The area reached by the edge; the industrial monitoring lens 2 is electrically connected to the image monitor 3 and the video capture card 4 through a cable; the video capture card is electrically connected to the computer processing system 5.

[0015] The working principle and working process of the present invention are as follows:

[0016] Such as figure 1 , 2 As shown, the industrial monitoring lens 2 can be arranged in the float glass production line tin bath, tin bath outlet, annealing kiln and annealing kiln outlet. The preferred solution is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com